Our 3HSS2260 is a hybrid high power stepper servo drive. It fits the NEMA 34 and NEMA 42 three-phase stepper motor. Compared to the traditional open-loop stepper driver, this stepper servo driver can completely avoid the stepper motor lost step problem, the high speed torque decrease is extremely lower than the open-loop stepper driver, greatly enhance the performance and torque of high speed motor. The driver current can be automatic controlled based on the load, it effectively restrain the temperature rise of the motor, extend the motor working life. Build-in position and alarm signal output are convenient for host computer to monitor and control the motor running state. The function of over position error alarm ensure the equipment working safely. It is the ideal replacement and upgrade of traditional open loop driver, and it is also with part functions of AC servo system, price is only half of the AC system.

1.Features

● 32-bit DSP and vector closed-loop control technology

● Without losing step, high accuracy in position

● Improve the motor output torque and working speed

● Variable current control technology, restrain motor temperature rise

● Adapt to variety of mechanical load conditions(including low-rigidity pulleys), no

need to adjust the gain parameter

● Smooth and reliable moving, low vibration, great improvement in accelerate and decelerate

● The ability of zero speed static without vibration

● Adapt to 3-phase NEMA34 and NEMA 42 hybrid servo motor

● Maximum step-pulse frequency 200KHZ

● Micro step 400-60000 pulse/rev

● Voltage range AC150-240V

● Over current, over voltage and over position protection

● Six digital tube display, easy to set parameters and monitor the motor running state

2.Electrical Parameter

Input Voltage |

AC150~240V (Typically use 220VAC) |

Current output |

Peak 6.0A(current variable based on load) |

Logic Current Input |

7~20mA |

Frequency |

0~200KHz |

Suitable motor |

3-phase nema 34 and nema 42 hybrid servo motor |

Encoder Resolution |

1000 |

Insulation Resistance |

≥500MΩ |

3.Environment Parameter

Cooling Method |

Natural cooling or forced air cooling |

Working Environment |

Avoid dust, oil fog and corrosive gasses |

Working Temperature |

0~50℃ |

Humidity |

40~90%RH |

Vibration |

5.9m/s²Max |

Storage temperature |

-20℃~65℃ |

3.Power Interface Ports1

Port |

Symbol |

Definition |

Remark |

1 |

L |

Motor power Connector to 220AC |

|

2 |

N |

|

|

3 |

NC |

Not Connected |

|

4 |

BR |

Braking Resistor |

External braking resistor connected between Br and P+ |

5 |

P+ |

DC Bus Voltage |

4.Power Interface Ports2

Port |

Symbol |

Definition |

NEMA34 |

NEMA42 |

1 |

U |

Motor Connection Port U |

Red |

Black |

2 |

V |

Motor Connection Port V |

Black |

Brown |

3 |

W |

Motor Connection Port W |

Blue |

Blue |

4 |

PE |

Ground |

yellow |

yellow |

5 |

L |

Controller power Connect to 220VAC |

Range AC150-220V |

|

6 |

N |

|||

5.Control Signal Interface Ports

Port |

Symbol |

Definition |

Remark |

3 |

PUL+ |

Pulse Signal Input + |

|

4 |

PUL- |

Pulse Signal Input - |

|

5 |

DIR+ |

Direction Signal Input + |

|

6 |

DIR- |

Direction Signal Input - |

|

7 |

ALM+ |

Alarm Signal Output + |

|

8 |

ALM- |

Alarm Signal Output - |

|

9 |

PEND+ |

Position Signal Output + |

|

10 |

PEND- |

Position Signal Output - |

|

11 |

ENA+ |

Enable Signal Input + |

|

12 |

ENA- |

Enable Signal Input - |

|

23 |

OA+ |

Encoder A Output |

Encoder A,B,Z Signal differential drive(26LS31) output, non-isolated output. If the motor only with A,B two channel encoder, then ignore Z channel. |

24 |

OA- |

||

25 |

OB+ |

Encoder B Output |

|

26 |

OB- |

||

27 |

OZ+ |

Encoder Z Output |

|

28 |

OZ- |

||

29 |

CZ |

Encoder Z open collector output |

|

30 |

GND |

Ground |

|

6.Encoder Signal Input Interface Ports

Port |

Symbol |

Definition |

Remark |

1 |

EA+ |

Encoder A+ Input |

If the motor only with A,B two channel encoder, then ignore Z channel. |

11 |

EA- |

Encoder A- Input |

|

2 |

EB+ |

Encoder B+ Input |

|

12 |

EB- |

Encoder B- Input |

|

7 |

EZ+ |

Encoder Z+ Input |

|

8 |

EZ- |

Encoder Z- Input |

|

13 |

VCC |

+5V |

|

3 |

GND |

Ground |

7.RS232 Communication Interface Ports

Port |

Symbol |

Definition |

1 |

NC |

Not Connected |

2 |

+5V |

For External HISU |

3 |

TxD |

RS232 Transmission Port |

4 |

GND |

Ground |

5 |

RxD |

RS232 Receiving Port |

6 |

NC |

Not Connected |

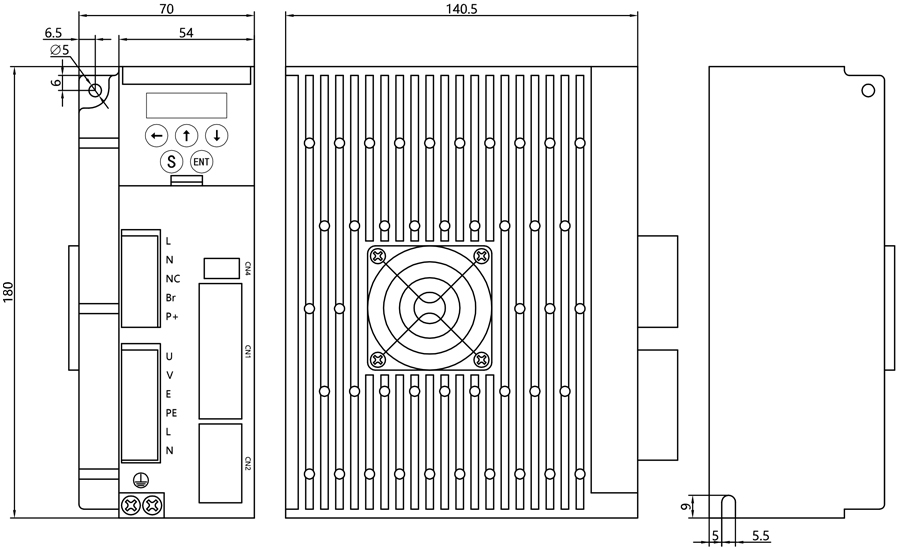

8.Overall Dimensions(unit=mm)

9.Custom Service

We provide a variety of customization options in the design, such as output shaft type, connectors, brakes, encoders and gearboxes, etc. Users can flexibly choose according to actual needs. Also can be designed & manufactured with special customized request.

10.Options

Wires |

Flange |

Shaft |

Screw |

|

|

|

|

Encoder |

Brake |

Gearbox |

And More |

|

|

|

+ |

11.Certificate

We have passed the ISO-9001 quality certification system and obtained a number of application patents. Our products have international certifications such as CE and ROHS.

12.Review

Copyright © 2026 Changzhou Jinsanshi Mechatronics Co., Ltd. All rights reserved. - Privacy policy