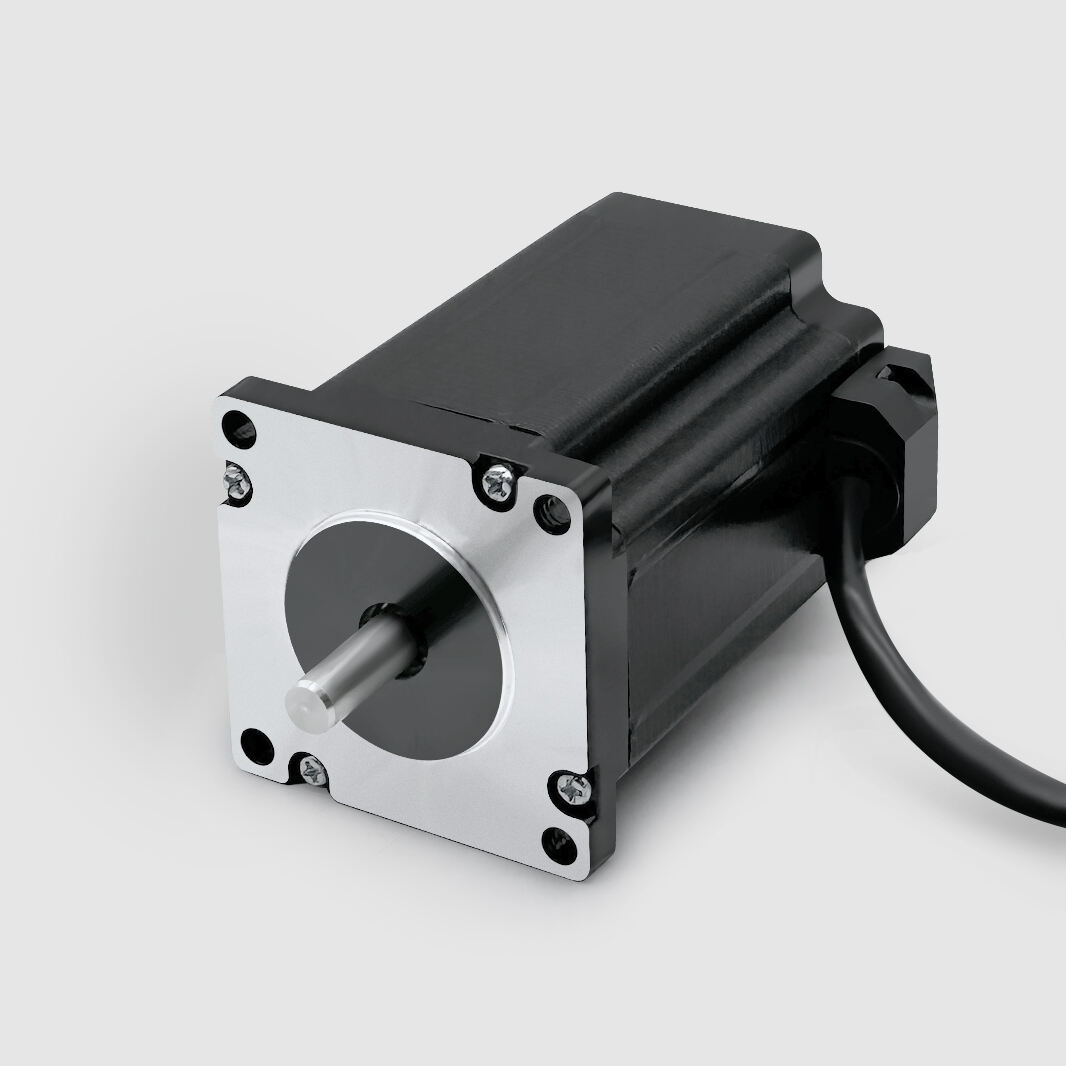

ac servo motor control system

The AC servo motor control system is a sophisticated technology designed to provide precise and efficient control over the operation of AC servo motors. Its main functions include speed control, position control, and torque control, enabling a wide range of applications from industrial automation to robotics. Technological features such as high responsiveness, accurate positioning, and excellent stability make it a preferred choice for systems that require high-precision and reliable performance. With features like closed-loop feedback and adaptive control, the system ensures that the motor operates with optimal efficiency and minimal error. Applications of the AC servo motor control system span across various industries including manufacturing, packaging, textiles, and medical devices, where precision and reliability are paramount.