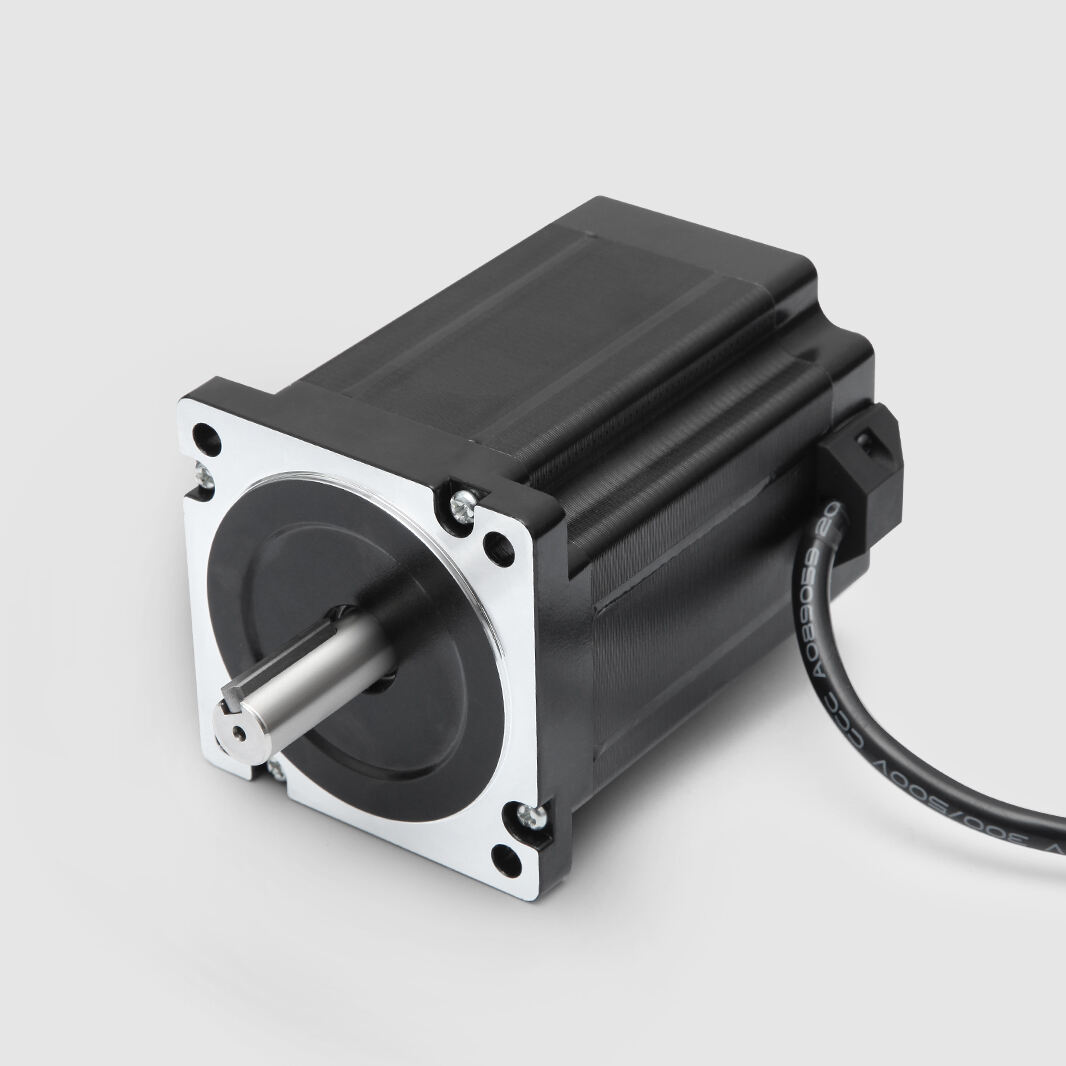

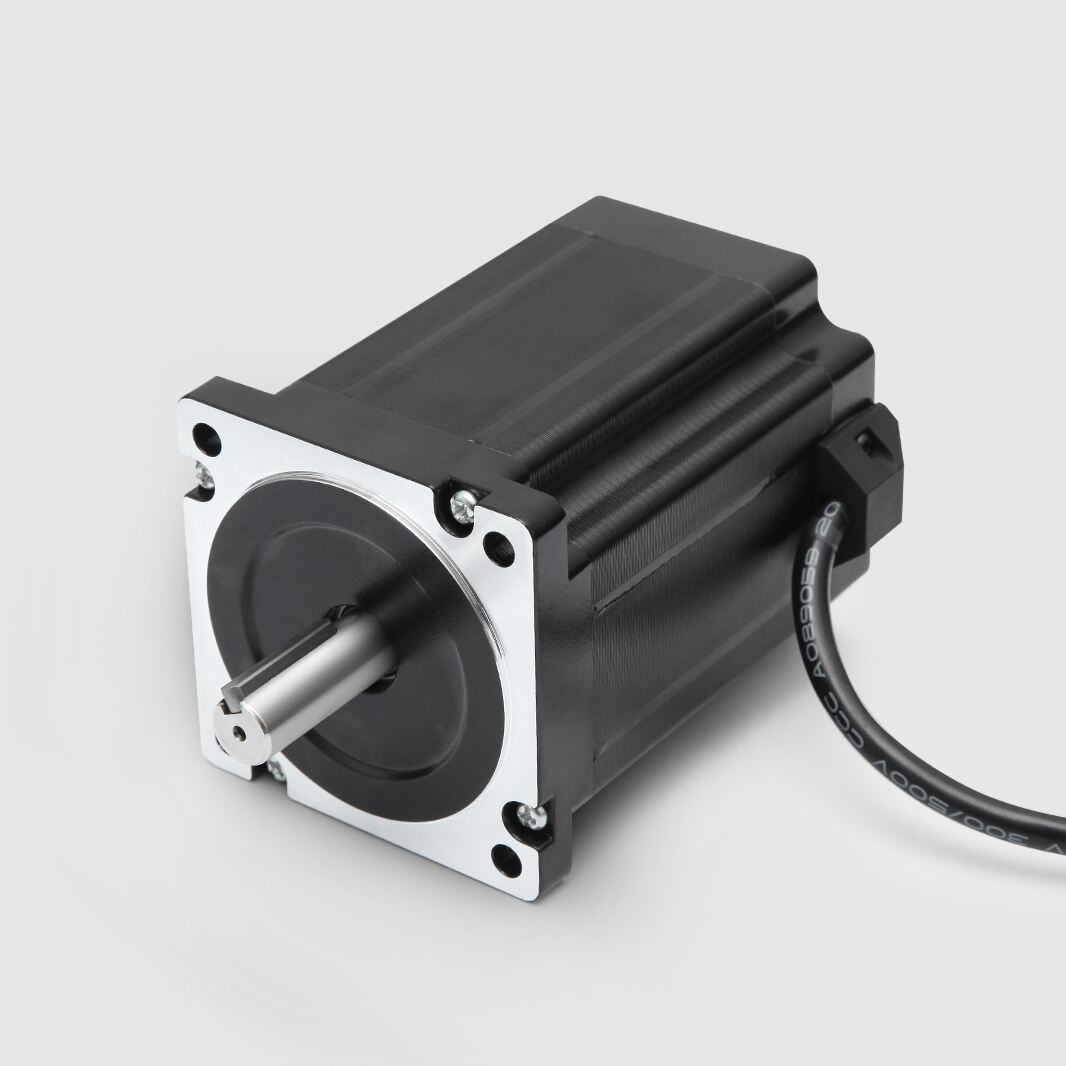

Advanced Protection Features

The NEMA 34 motor driver comes equipped with advanced protection features, including overload protection and thermal shutdown. These features work together to safeguard the motor and driver from damage caused by excessive current or heat. In the event of an overload, the driver automatically reduces the current to safe levels, preventing potential damage to the motor windings. Similarly, if the temperature exceeds safe limits, the thermal shutdown feature activates, ceasing operation until the driver cools down. These protective measures extend the lifespan of the motor driver, minimize downtime, and reduce maintenance costs. For customers, this translates to a more reliable and durable solution that offers peace of mind and lower total cost of ownership.