Understanding the Fundamentals of Step Motor Technology

Step motors, also known as stepper motors, are the workhorses of precision motion control in modern automation and engineering. These versatile devices convert electrical pulses into precise mechanical movements, making them essential components in everything from 3D printers to industrial machinery. To make an informed decision about the right step motor for your application, it's crucial to understand how these remarkable devices operate and what makes them uniquely suited for precise positioning tasks.

At their core, step motors operate by converting digital pulses into discrete mechanical movements. Each pulse rotates the motor shaft through a fixed angle, allowing for precise control over position, speed, and rotation. This fundamental characteristic sets them apart from conventional motors and makes them invaluable in applications requiring exact positioning and repeatable motion control.

Essential Step Motor Specifications and Parameters

Torque Ratings and Performance Metrics

When selecting a step motor, torque specifications serve as a critical starting point. The holding torque indicates the maximum force the motor can maintain at standstill, while dynamic torque relates to the motor's capability during rotation. Understanding these specifications helps ensure your motor can handle the intended load without losing steps or stalling.

Engineers must consider both the starting torque and running torque requirements of their application. A motor that seems adequate based on holding torque alone might struggle when dealing with dynamic loads or high-speed operations. It's essential to factor in safety margins and account for varying load conditions throughout the operating cycle.

Resolution and Step Accuracy Requirements

The step angle and positioning accuracy of a step motor directly influence its suitability for specific applications. Standard step motors typically offer step angles of 1.8 or 0.9 degrees, translating to 200 or 400 steps per revolution respectively. Modern microstepping techniques can further divide these steps, achieving even finer resolution.

When evaluating resolution requirements, consider both the basic step angle and the potential benefits of microstepping. While microstepping can provide smoother operation and finer positioning, it may come at the cost of reduced torque and increased system complexity.

Mechanical and Environmental Considerations

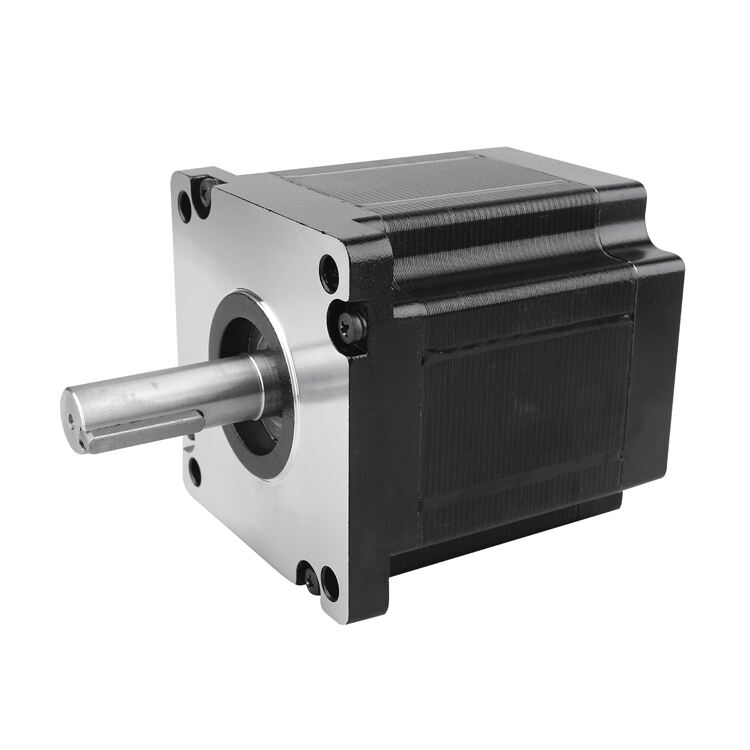

Physical Dimensions and Mounting Options

The physical size and mounting configuration of a step motor must align with your project's space constraints and mechanical interface requirements. Standard NEMA frame sizes provide a consistent mounting pattern, but overall motor length, shaft dimensions, and bearing configurations can vary significantly between models.

Consider not just the current space requirements but also future maintenance accessibility and potential system modifications. Proper mounting and alignment are crucial for optimal performance and longevity of the step motor system.

Environmental Protection and Operating Conditions

Step motors must withstand the environmental conditions of their intended application. Temperature ranges, humidity levels, and exposure to dust or chemicals can all impact motor selection. IP ratings indicate the level of environmental protection, with higher ratings necessary for harsh industrial environments or outdoor applications.

Heat dissipation capabilities become particularly important in high-duty-cycle applications or enclosed spaces. Proper ventilation or additional cooling measures may be necessary to maintain reliable operation and prevent thermal damage to the motor windings.

Electrical Integration and Control Requirements

Power Supply and Current Specifications

The electrical characteristics of a step motor system significantly influence both performance and driver requirements. Voltage ratings, current per phase, and inductance values must be compatible with your available power supply and chosen driver circuit. Higher voltage ratings generally allow for better high-speed performance, while current ratings directly affect torque output.

Modern step motor drivers offer various current control features to optimize performance and efficiency. Understanding the relationship between motor electrical specifications and driver capabilities ensures proper system integration and reliable operation.

Control Interface and Communication Protocols

The control requirements of your application may influence motor selection, particularly when considering integrated solutions. Some step motors come with built-in controllers or encoders, while others require external control systems. The choice between open-loop and closed-loop control can affect both system cost and performance reliability.

Communication protocols and control interfaces must align with your existing automation infrastructure. Consider whether you need simple step/direction control or more advanced features like network connectivity and real-time position feedback.

Cost Considerations and Long-term Value

Initial Investment versus Operating Costs

While the initial purchase price of a step motor is important, it shouldn't be the sole determining factor. Consider the total cost of ownership, including installation, maintenance requirements, and energy efficiency. Higher-quality motors may command premium prices but often deliver better reliability and performance over their operational lifetime.

Factor in the cost of associated components such as drivers, controllers, and power supplies. A more expensive motor with integrated features might prove more economical than a cheaper option requiring additional external components.

Reliability and Maintenance Requirements

The reliability of a step motor system directly impacts long-term operational costs. Quality construction, proper sizing, and appropriate protection features can significantly reduce maintenance requirements and prevent costly downtime. Consider the manufacturer's reputation and warranty terms when evaluating different options.

Preventive maintenance schedules and spare parts availability should also factor into the selection process. Some applications may justify redundant systems or quick-change mounting options to minimize potential disruption to operations.

Frequently Asked Questions

What is the difference between a step motor and a servo motor?

Step motors operate by converting digital pulses into discrete mechanical movements, typically in an open-loop configuration. Servo motors, in contrast, use closed-loop feedback control and can provide smoother operation with higher dynamic performance. Step motors excel in applications requiring precise positioning at lower speeds, while servo motors are better suited for high-speed, variable-load applications.

How does microstepping affect step motor performance?

Microstepping divides the basic step angle into smaller increments, resulting in smoother operation and finer position control. However, it typically reduces the available torque and may introduce some position uncertainty at very fine resolutions. The practical benefits of microstepping depend on the specific application requirements and the quality of the control system.

Can step motors be used in continuous rotation applications?

While step motors are designed for precise positioning, they can certainly be used in continuous rotation applications. However, they tend to be most efficient at lower speeds and may require careful consideration of heat dissipation and torque requirements. For high-speed continuous operation, other motor types might be more suitable.