Understanding Hybrid Stepper Motors

Hybrid stepper motors basically take what works from permanent magnet motors and variable reluctance designs, which gives them better torque and more accurate positioning. What makes these motors special is how they bring together elements from both worlds one side has a permanent magnet rotor while the other features those toothed components we see in variable reluctance systems. The way these parts work together means the motor can grab onto magnetic fields much better than either type alone. That's why engineers love seeing them in precision machinery where small movements matter a lot, like in medical devices or industrial automation setups where accuracy just cant be compromised.

Hybrid stepper motors show up all over the place in things like CNC machines, 3D printers and robots wherever someone needs really fine control over how something moves. Industry folks have been talking about this for a while now the market for these motors seems set to grow pretty fast as more industries realize they need better motion control solutions. What makes these motors so special? They can move things with pinpoint accuracy again and again without losing their precision. That's why manufacturers keep coming back to them whether it's for factory automation systems or even delicate medical equipment where getting the movement right matters a lot.

Hybrid stepper motors work by moving in distinct steps, which gives operators much better control when it comes to positioning things accurately. Because of this stepping mechanism, these motors are really good at jobs where exact placement matters a lot and speed needs to be carefully managed. Each move happens in tiny increments usually around 1.8 degrees per step allowing for pretty detailed control. That kind of precision makes them popular in areas like automated manufacturing systems or electronic devices where getting things just right is absolutely critical for proper function.

Lower Efficiency at High Speeds

When hybrid stepper motors run at higher speeds, they tend to struggle with efficiency issues mainly because of heat generation and torque ripple problems. The faster they spin, the worse these problems get as heat builds up and wastes a lot of energy. Take for example the various losses that happen inside these motors - things like hysteresis effects, those annoying eddy currents, plus regular old mechanical friction all combine to make them pretty inefficient compared to other options on the market. Servo motors and their controllers just handle high speed operations much better in practice, making them a smarter choice for applications where performance matters most.

When it comes to high speed operations, these inefficiencies really show themselves. Hybrid stepper motors often have trouble holding onto their rated torque when things start moving fast, which leads to performance drops that operators definitely notice. For industries where consistent torque matters most at those higher speeds, this becomes a real problem. Think about robotics assembly lines or any kind of rapid manufacturing setup. Sure, these motors work great for precise movements at slower speeds, but once things pick up pace, they just cant keep up. That means engineers need to look closely at what kind of motor makes sense for each application, especially if the system needs to handle demanding tasks without losing power or accuracy.

Complexity and Cost

Making hybrid stepper motors is no easy task for manufacturers who want them to perform at their best. The whole process demands extremely careful placement of parts and complicated design work just to get those precise movements right. Because of this attention to detail, producing these motors ends up being much harder work compared to basic motor types. And let's face it, all that extra care comes at a price tag that sits well above what we see with simpler options like brushed DC motors on the market today.

Hybrid stepper motors tend to cost more to manufacture compared to basic motor types, something that definitely eats into project budgets. The reason? These motors come packed with enhanced performance specs that require better quality components and more sophisticated manufacturing processes. As a result, manufacturers pass along these higher costs to customers, making the final price tag quite steep for anyone needing multiple units. For companies working within tight financial constraints, this added expense can create serious challenges when planning long term investments in automation systems that rely heavily on such specialized equipment.

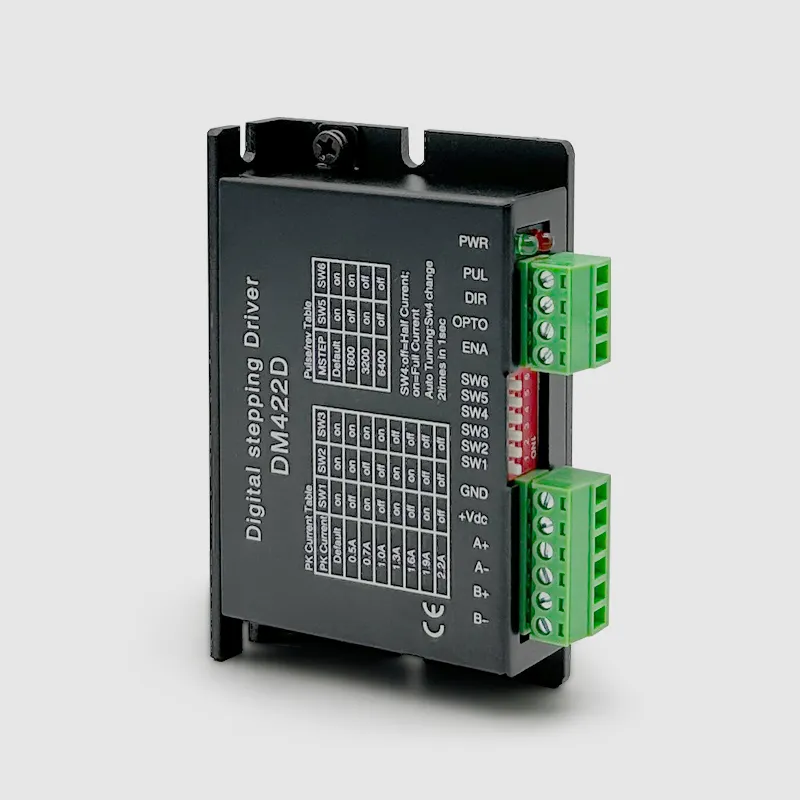

Hybrid stepper motor systems generally need pretty advanced controllers just to work properly. The controllers themselves are important because they handle all those complicated calculations needed to make sure the motor moves exactly where it needs to go. Getting into these control systems means extra money spent upfront and ongoing costs too. For companies thinking about switching to hybrid steppers, this is something worth keeping in mind when looking at options like brushless DC motors paired with encoders or even smaller DC servo motors which might be cheaper overall depending on the application requirements.

Heat Generation

Too much heat remains one of the biggest problems when running hybrid stepper motors, impacting how well they work and how long they last. When these motors run nonstop, they often push past their safe temperature thresholds, which knocks down their overall performance. Take for example most hybrid stepper motors that generally handle temperatures up to around 85 degrees Celsius before things start going wrong according to research from the Algerian Journal of Renewable Energy back in 2022. The extra heat doesn't just slow them down either it actually makes them fail sooner than expected. Windings inside the motor and its insulation layers tend to wear out faster under constant heat stress, eventually causing complete system failures if left unchecked.

Getting rid of excess heat is really important for keeping things running properly. Cooling fans work well for this job, along with those metal plates called heat sinks and some newer materials that sit between components. These all help push away heat so temperatures stay where they should be. Sometimes engineers will tweak how much power gets used through methods like micro-stepping, which cuts down on heat generation too. When manufacturers put these cooling approaches into their designs, it makes hybrid stepper motors last longer and run better over time. Motors last longer means fewer replacements needed, especially when they're working hard in tough environments day after day.

Noise and Vibration

Hybrid stepper motors tend to make quite a bit of noise and vibration because they have all those moving parts and that characteristic stepping action. What happens is these mechanical components start to resonate at particular frequencies, which creates unwanted disturbances. For many applications this becomes a real problem when silence matters most. Think about things like medical devices or lab equipment where even small amounts of background noise can interfere with sensitive measurements. The precision of the stepping motion is great for accuracy, but it also brings along those regular vibrations that engineers often need to find ways around in actual installations.

Noise and vibration really throw things off in places that need exact measurements. When working with equipment that demands pinpoint accuracy, it's essential to get rid of these unwanted movements somehow. There are several ways to tackle this problem. Some folks install those rubbery mounts between machines and surfaces, while others slap on special materials that soak up the shakes. These methods work pretty well for keeping instruments running smoothly. The whole point is to make sure everything stays accurate over time, especially when dealing with delicate operations where even tiny disruptions matter a lot. Factories save money too because fewer breakdowns mean less downtime and wasted materials.

Limited Torque at Low Speeds

When running at slower speeds, hybrid stepper motors tend to lose some of their torque power, which can be pretty limiting for specific uses. Because of how their torque works, these motors just aren't great choices whenever there's a need for strong force at low speeds. Think about things like those conveyor belts that move really slowly through factories, or machines where exact control matters a lot during production processes. For situations like this, other options start looking better. Small DC servo motors work well here, along with brushless DC motors equipped with encoders. These alternatives deliver steadier torque no matter what speed they're operating at, so many engineers actually prefer them when dealing with applications where consistent performance is critical.

Getting familiar with torque limitations matters a lot when building systems that need to work across different speed ranges. Many applications require steady performance and good torque whether running fast or slow, so sometimes going with integrated setups makes sense. Stepper motors paired with controllers often handle these situations better since they're built for exactly this kind of workload. Take hybrid servo motors as another option. These combine features from both stepper and DC motors but avoid the problem where torque drops off at lower speeds. That's why they show up in so many industrial settings nowadays. When engineers actually look at what their systems need instead of just picking whatever's available, they tend to select motors that perform well under all conditions, not just in theory.

Conclusion

Hybrid stepper motors come with quite a few downsides worth noting. They tend to be inefficient when running at higher speeds, plus they're complex systems that generate heat and make noise. Not to mention their torque drops off pretty badly at lower speeds. All these issues really matter for certain applications where performance counts. Before going with hybrid steppers, anyone working on a project should take time to weigh these limitations against what their particular setup actually needs. Looking into other options such as servo motors might offer better results for those demanding top notch performance from their equipment. At the end of the day, knowing exactly what kind of workload an application will face makes all the difference in picking the right motor technology for the job.

FAQ

What are the main advantages of hybrid stepper motors?

Hybrid stepper motors offer higher torque and precision by combining features of permanent magnet and variable reluctance motors. They are highly suitable for applications requiring meticulous positioning and speed regulation, making them valuable in fields such as CNC machinery, 3D printing, and robotics.

Why do hybrid stepper motors experience inefficiencies at high speeds?

Hybrid stepper motors face energy losses in the form of heat and torque ripple at high speeds. This is due to hysteresis, eddy current losses, and mechanical friction, leading to decreased performance compared to solutions like servo motor systems that can efficiently handle high speeds.

How does heat generation affect hybrid stepper motor performance?

Excessive heat output can degrade motor performance and lead to component failure. Effective cooling solutions, like fans and heat sinks, and power management techniques like micro-stepping, can help maintain operational efficiency and extend motor life.

What applications might not be suitable for hybrid stepper motors?

Applications requiring high torque at low speeds, such as slow-moving conveyor systems, may not be ideal for hybrid stepper motors. In these cases, alternatives like small DC servo motors or brushless DC motors with an encoder are recommended due to their ability to deliver consistent torque regardless of speed.