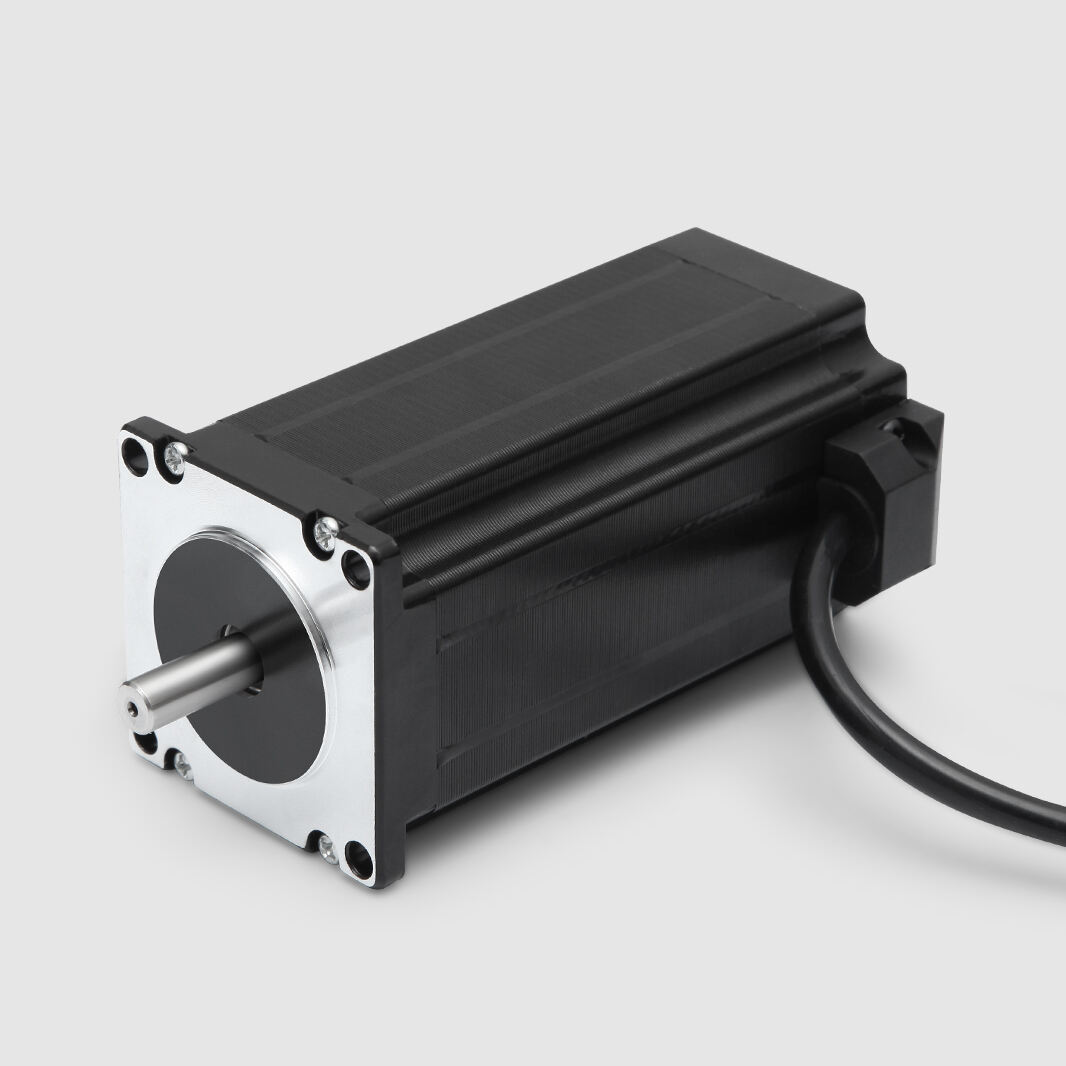

Introduction to NEMA 23 Hybrid Stepper Motors

NEMA 23 stepper motors are integral components in automation systems thanks to their optimal balance of size and capability. These motors fall under the National Electrical Manufacturers Association (NEMA) standard, which ensures uniform dimensions and mounting specifications, making them a consistent choice for various mechanical and electrical applications.

NEMA 23 motors have become pretty much standard equipment in many different sectors thanks to how adaptable they are. We see them everywhere from small workshops running 3D printers to big manufacturing floors where they power those precise CNC machines that cut metal with surgical accuracy. What really keeps these motors going strong in the market is their unique hybrid setup. Basically, they take what works best from two types of motor technology - the magnets that stay charged forever and the ones that rely on magnetic resistance changes. This mix gives manufacturers something special: extra force when needed without sacrificing control over tiny movements, which matters a lot when making parts that need to fit together perfectly.

By blending these features, NEMA 23 hybrid stepper motors offer enhanced stability and efficiency, making them a popular choice in both industrial and hobbyist settings. Their consistent performance and adaptability set the standard for stepper motors, fostering innovation and efficiency in applications requiring precise motion control.

Structural Differences Between Standard and High-Precision Hybrid Motors

Basic Design of Standard Hybrid Motors

Most standard hybrid motors come with a stepper rotor and stator setup, focusing on keeping costs down while still covering a wide range of functions. The materials used in these motors tend to be pretty basic, not really built for extreme precision but just fine for everyday tasks. Efficiency levels usually hit right around what's needed for regular automation work, making them decent performers without breaking the bank. When it comes to configuration options, manufacturers typically offer straightforward adjustments that work well enough for common industrial jobs we see in places like textile factories or entry level CNC shops where complex motor requirements aren't part of daily operations.

Enhanced Construction of High-Precision Hybrid Motors

The latest generation of high precision hybrid motors comes from some pretty impressive engineering work that really boosts how well they perform. These motors feature better magnetic circuits along with rotor designs that have been fine tuned over time, all working together to cut down on those annoying operational errors we see in older models. What makes these motors stand out is the quality of materials used during production plus manufacturing methods that push the boundaries of what's possible. The end result? Motors that make fewer mistakes and respond much quicker than traditional ones. Take step angles for example - while most standard motors operate at around 1.8 degrees per step, these new hybrids manage just 0.9 degrees. That means twice the precision when moving parts need to be positioned accurately, something that matters a lot in industries where even small movements count.

Additionally, the integration of such advanced features allows high-precision hybrid motors to maintain high standards of movement smoothness and low vibration levels, essential for intricate operations in medical devices and high-end CNC machines. This technological enhancement ensures their wide adoption in industries where precision and reliability are critical.

Step Angle and Resolution: Standard vs. High-Precision

Standard Hybrid: 1.8° Step Angle

Most standard hybrid motors come with a step angle around 1.8 degrees, meaning they take about 200 steps to complete one full rotation. This particular step size strikes a good middle ground when it comes to both torque output and how finely we can control movement, so it works pretty well across many different situations. Take hobby robotics projects for instance. When building robots at home, people often care more about keeping costs down while still getting decent accuracy from their movements. The 1.8 degree step angle fits right into that sweet spot most of the time. Many makers turn to NEMA 23 stepper motors for these kinds of projects because they deliver solid performance without needing super high resolution capabilities that would drive up prices unnecessarily.

High-Precision Hybrid: 0.9° or Smaller Step Angle

Hybrid motors that offer high precision typically feature step angles around 0.9 degrees or even smaller, resulting in over 400 steps for each full rotation. This level of detail gives better control, making them great choices for tough situations where things need to be just right, especially in areas like computer controlled machining tools and robotic systems used in hospitals. When there's more resolution available, movements become much smoother and positioning gets really accurate. That kind of precision matters a lot when working on delicate procedures with surgical robots or running complex manufacturing machines that demand exact measurements. These motors work by having twice as many rotor teeth compared to standard models, which cuts down on vibrations quite a bit and makes everything run more smoothly overall. The result? Better performance across all sorts of advanced machinery setups.

Torque and Holding Power Comparison

Standard: Balanced Torque for General Applications

Hybrid stepper motors of the standard variety generally offer good torque balance, which works well for many everyday applications. Most models put out enough torque to handle regular machine operations while keeping costs reasonable for budget conscious buyers. When looking at different work conditions, these motors tend to maintain stable torque levels that can be counted on day after day. They show up everywhere from weekend DIY setups to entry level robotic systems. The fact that they strike this middle ground makes them pretty popular among folks who need something functional but don't require extreme power output for their mechanical projects.

High-Precision: Higher Torque Stability for Precision Tasks

Hybrid motors with high precision really stand out when it comes to delivering stable torque, something absolutely necessary for jobs where performance needs to be spot on. What makes these motors special is their ability to keep torque levels steady even when loads change around them, and this matters a lot in situations where precision is everything. Take laser cutting operations or those complicated industrial automation setups we see everywhere now. The extra stable torque means machines run exactly how they should. Looking at actual usage stats, things like CNC machining centers and top tier robotic systems get major benefits from these motors because they can hold that higher torque for much longer than standard alternatives. That's why so many manufacturers specify them for work that demands both complexity and pinpoint accuracy.

Performance in Motion Control Applications

Standard: Suitable for Basic Automation and Robotics

Hybrid motors work pretty well for straightforward automation jobs and robots that operate in stable environments. Most factories install these motors on entry level robotic arms, conveyors moving parts around assembly lines, and similar equipment found throughout industrial facilities. People keep coming back to them because they just plain work reliably day after day. Manufacturing plants have been using them extensively for years now, especially when dealing with repetitive motions that don't require fancy features. What makes these motors stand out is how they deliver enough power without overcomplicating things, meeting most factory needs while keeping maintenance costs down and operations running smoothly.

High-precision: Ideal for CNC, Medical, and Scientific Applications

Hybrid motors with high precision work really well in situations that need tight control over tolerances. Think about things like CNC machines, medical gear, and lab instruments. These motors keep performing consistently, which matters a lot when mistakes could cost big time. Just small changes in operation might result in major problems down the line. Take medical devices for instance - getting the measurements right there literally saves lives. Looking at actual experiences in the CNC world shows us how these motors help remove materials exactly as needed, making complex designs possible and boosting what comes out of production lines. No wonder so many industries rely on them whenever they need something both accurate and dependable.

Cost and Application Considerations

Standard: Cost-effective, widely used in general motion control

Hybrid motors in standard configurations tend to save money, which explains why so many companies pick them for basic motion control tasks. Businesses wanting to keep expenses down but still get decent performance often go this route since these motors deliver good results without charging what the high precision versions demand. Take Moons' standard hybrids for instance they're priced lower than their specialized counterparts and show up all over places where spending isn't the main concern. The bottom line remains affordability makes these motors stand out when budgets matter most in project planning.

High-precision: More expensive but necessary for ultra-precise positioning

When it comes to applications needing pinpoint accuracy, high precision hybrid motors just make sense even though they come with a bigger price tag. These motors command top dollar because they simply cannot be replaced in situations where exact control matters most and errors aren't an option. Manufacturing shops and hospitals spend extra on them all the time since there's literally no room for mistakes in things like CNC machines or surgical tools. Industry insiders have been pushing for these motors across various sectors for years now, mainly because nothing else matches their level of accuracy when it counts. Most manufacturers run the numbers through cost benefit analyses before pulling the trigger on purchase decisions. What they find usually confirms what anyone who works closely with machinery already knows the long term gains from better quality and fewer breakdowns far outweigh the initial expense.

Conclusion

Picking out the correct hybrid stepper motor isn't something to take lightly. It takes some serious thinking about what level of accuracy matters most and what kind of work the motor will actually be doing day to day. When looking at different options, it's pretty important to know whether we're dealing with regular motors or those fancy high precision ones. Regular models tend to be cheaper and work fine for basic movement tasks around the shop floor. But when things need pinpoint accuracy, like in medical equipment or precision manufacturing setups, that's where the high end motors shine. Getting this straight helps match motor capabilities to actual job requirements without spending extra money on features nobody really needs.

Industry professionals need to carefully match their project requirements with what standard and high precision motors can actually deliver. Making sure the selected motor fits the job at hand means getting good results without overspending on unnecessary features. A proper assessment helps avoid wasted resources while still meeting all necessary performance standards. Smart selection based on real-world needs leads to better long term value and keeps budgets under control without compromising quality.

FAQ Section

What are the main applications of NEMA 23 hybrid stepper motors?

NEMA 23 hybrid stepper motors are commonly used in CNC machines, 3D printers, and robotic systems due to their reliable performance and precision.

What is the difference between standard and high-precision hybrid motors?

Standard hybrid motors are more cost-effective and provide balanced torque and precision for general applications, while high-precision motors offer enhanced accuracy and stability for demanding tasks requiring minimal error.

Why are high-precision hybrid motors more expensive?

The premium cost of high-precision hybrid motors is due to their advanced engineering, superior materials, and enhanced performance metrics. They are designed for environments where precise motion control is critical, justifying their higher price.

How do step angles affect motor performance?

Step angles determine the motor's resolution and torque balance. Smaller angles (e.g., 0.9°) provide greater resolution and smoother motion, suitable for high-precision tasks, whereas larger angles (e.g., 1.8°) are adequate for general applications.

Table of Contents

- Introduction to NEMA 23 Hybrid Stepper Motors

- Structural Differences Between Standard and High-Precision Hybrid Motors

- Step Angle and Resolution: Standard vs. High-Precision

- Torque and Holding Power Comparison

- Performance in Motion Control Applications

- Cost and Application Considerations

- Conclusion

- FAQ Section