In recent years, with the rapid development of power electronics and the widespread adoption of intelligent and automated machinery, motor technology has entered a new era. High-precision industries such as electronics manufacturing, medical devices, aerospace, and robotics are placing increasingly stringent requirements on motor performance—especially in terms of speed accuracy, torque stability, noise control, and long-term reliability.

Against this backdrop, the Permanent Magnet Brushless DC Motor (BLDC Motor) has become one of the mainstream and most trusted choices in the global market.

Why Choose a Brushless DC Motor? — Precision, Performance & Durability All in One

Compared with brushed DC motors, BLDC motors eliminate mechanical brushes and rely on electronic commutation, offering significant advantages:

Thanks to these features, BLDC motors are widely used in UAVs, robotics, AGV vehicles, ventilators, power tools, compressors, pumps, and smart home appliances.

Internal Structure of a Permanent Magnet Brushless DC Motor

A BLDC motor is a three-phase motor powered by a DC supply and driven through electronic commutation. It consists mainly of:

Depending on the method used to detect rotor position, BLDC motors can be classified into two types:

1. Hall Sensor Brushless DC Motors (Sensored BLDC)

Equipped with position sensors (e.g., Hall sensors) to monitor rotor magnetic pole position. The MCU performs accurate commutation based on the sensor signal.

Ideal for:

2. Sensorless Brushless DC Motors

Rotor position is detected through the back-EMF of the windings.

Advantages include:

Both types of BLDC motors can be fully customized according to your voltage, torque, KV value, dimensions, shaft type, and wiring requirements.

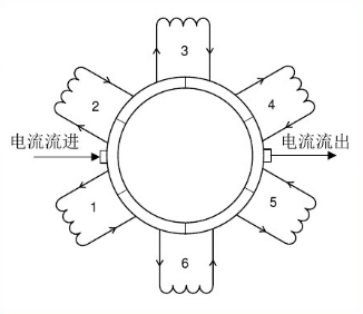

Motor Winding & Commutation Principle

The stator contains six coils forming three winding pairs (A, B, C phases). Within each cycle, only two phases are energized. The commutation sequences are:

To minimize losses and maximize torque, commutation must occur when the stator magnetic field is perpendicular to the rotor magnetic field—this is critical for achieving high performance in BLDC motors.

Motor Performance Formulas (Frequently Asked by Buyers)

1. Speed formula

n = 60f / P

n: speed (r/min) f: electrical frequency P: number of pole pairs

2. Torque formula

T = 9550P / n

T: torque (N·m) P: output power (kW) n: speed (r/min)

For example:

Our engineering team can assist with motor selection based on your required torque, power, and speed.

Applications: From Industrial Systems to Consumer Electronics

With exceptional efficiency and reliability, Permanent Magnet BLDC Motors are now used in:

Whether your priority is low noise, high speed, stability, or long-term durability, a BLDC motor remains the superior choice.

Our Advantages as a Professional BLDC Motor Supplier

We are committed to providing global customers with high-performance, precise, and reliable Brushless DC Motor solutions for long-term operation.

Copyright © 2026 Changzhou Jinsanshi Mechatronics Co., Ltd. All rights reserved. - Privacy policy