The JSS86P is an innovative integrated hybrid servo drive system with communication capabilities. It is merged the stepper servo driver and motor together. Featuring closed-loop technology, it prevents step loss and ensures precision. Its high-speed torque decay is significantly lower than traditional open-loop drives, dramatically enhancing the stepper motor's high-speed performance and torque. The load-based current control technology effectively reduces motor temperature rise, extending service life. Built-in position completion and alarm outputs enable convenient monitoring and control by the host computer. The position overrun alarm ensures safe operation of processing equipment.

Features

It uses advanced 32-bit ARM chip and closed-loop control technology;

It operates in closed-loop mode without losing steps, and also supports open-loop mode.

Increasing the output torque and running speed of the motor;

The current is intelligently adjusted according to the load to reduce motor temperature rise, with locked electromagnet current and adjustable closed-loop peak current;

It can adapt to all kinds of mechanical load conditions (including low rigidity pulley and pulley load), and does not need to adjust the gain parameters;

The time of position command smoothing filter can be set, the motor running more smoothly, the vibration is less, the dynamic performance of acceleration and deceleration is improved;

After positioning, the zero-speed static capability without vibration;

Supports single and dual pulse input, with a maximum pulse response frequency of 200kHz;

Supports 15 fixed fractional divisions and allows software-defined subdivisions (200 to 65535);

Supports Modbus RTU protocol on RS232, enabling position and speed control via communication;

Supports monitoring of motor operating conditions, including speed, position deviation, bus voltage, and operating current;

Voltage range: DC+24V to 80V;

It has over current, over voltage, and position deviation protection;

Electrical specifications

Model No. |

Step Angle |

Motor Length |

Current /Phase |

Resistance /Phase |

Inductance /Phase |

Holding Torque |

|

( °) |

(L1)mm |

(L2)mm |

A |

Ω±10% |

mH±20% |

N.m |

|

|

JSS86P-4.5N-BC38

|

1.8 |

82 |

128 |

4.5 |

0.7 |

5.5 |

4.5 |

|

JSS86P-6.5N-BC38

|

1.8 |

100 |

145 |

5.0 |

0.5 |

4 |

6.5 |

|

JSS86P-8.5N-BC38

|

1.8 |

118 |

163 |

6.0 |

0.5 |

4.5 |

8.5 |

|

JSS86P-10N-BC38

|

1.8 |

128 |

173 |

6.0 |

0.6 |

5 |

10 |

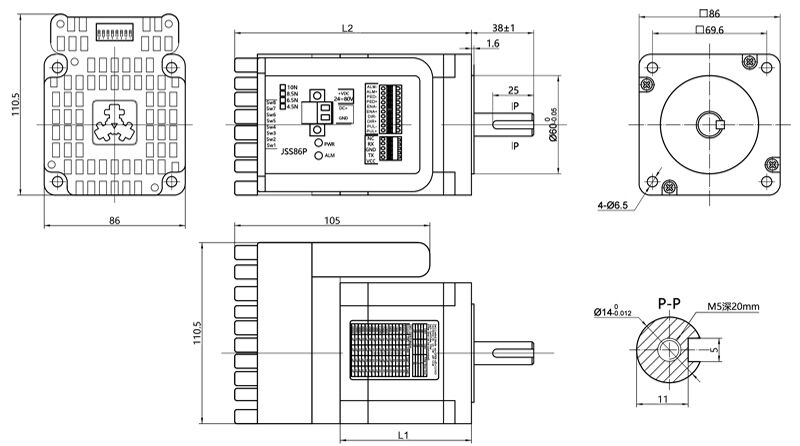

Overall Dimensions

Electrical indicators

Power supply |

DC+24~80V, recommended power supply: DC+60V |

Output current |

Peak 7.0A ((current varies with load) |

Logic input current |

7~16mA, recommended 10mA |

Pulse frequency |

0~200kHz |

Encoder line number |

1000 |

Insulation resistance |

≥500MΩ |

Usage environment and parameters

Cooling method |

Natural cooling or external radiator |

|

Use environment |

Use occasion |

Try to avoid dust, oil and corrosive gases |

Temperature |

0~40℃ |

|

Humidity |

40~90%RH |

|

Vibration |

5.9m/s2Max |

|

Storage temperature |

-20℃~80℃ |

|

Interface definition

Power input port

Terminal number |

Symbol |

Name |

Explain |

1 |

+Vdc |

Positive terminal of DC power supply |

DC+24V~48V Recommended DC+60V power supply |

2 |

GND |

DC power ground |

Control signal port

Terminal number |

Symbol |

Name |

Description |

1 |

PUL+ |

Pulse positive input |

Support 5~24V |

2 |

PUL- |

Pulse negative input |

|

3 |

DIR+ |

Direction Positive input |

|

4 |

DIR- |

Direction Negative input |

|

5 |

EN+ |

Enable positive input |

|

6 |

EN- |

Enable negative input |

|

7 |

PEND+ |

The arrival signal is outputting |

The OC gate output indicates that the closed position is the default, while the open position is not yet detected. |

8 |

PEND- |

Arrival signal negative output |

|

9 |

ALM+ |

Alarm signal is active |

The OC door output has an alarm signal for the default closed indicator, and no alarm signal for the open indicator. |

10 |

ALM- |

Negative alarm signal output |

RS232 communication port

Terminal number |

Symbol |

Name |

1 |

+5V |

Positive terminal of the power supply |

2 |

TXD |

RS232 transmitter |

3 |

GND |

Power supply ground |

4 |

RXD |

RS232 receiver |

5 |

NC |

|

Status indication

PWR: Power Indicator Light. The green light turns on when powered.

ALM: Fault indicator light. A single red light flash within 3 seconds indicates over current or phase-to-phase short circuit; two consecutive flashes within 3 seconds indicate over voltage fault; five consecutive flashes within 3 seconds trigger position error alarm.

DIP switch setting

JSS86 uses 8-bit DIP switch to set the filter time, motor rotation direction and subdivision precision.

SW1 controls the mode selection: on for open-loop control, off for closed-loop control.

SW2 controls the motor rotation direction: on (CW) for clockwise, off (CCW) for counterclockwise.

SW3~SW4 controls the filtering time for position commands. A longer filtering time ensures smoother motor operation and reduced noise. The filtering time can be flexibly adjusted via the host computer software.

SW3 |

SW4 |

Filter time (ms) |

ON |

ON |

0 (You can modify the filter time through communication in this gear) |

OFF |

ON |

3 |

ON |

OFF |

15 |

OFF |

OFF |

30 |

SW5, SW6, SW7, SW8: Subdivision settings.

Steps / circle |

SW5 |

SW6 |

SW7 |

SW8 |

Default |

ON |

ON |

ON |

ON |

800 |

OFF |

ON |

ON |

ON |

1600 |

ON |

OFF |

ON |

ON |

3200 |

OFF |

OFF |

ON |

ON |

6400 |

ON |

ON |

OFF |

ON |

12800 |

OFF |

ON |

OFF |

ON |

25600 |

ON |

OFF |

OFF |

ON |

51200 |

OFF |

OFF |

OFF |

ON |

1000 |

ON |

ON |

ON |

OFF |

2000 |

OFF |

ON |

ON |

OFF |

4000 |

ON |

OFF |

ON |

OFF |

5000 |

OFF |

OFF |

ON |

OFF |

8000 |

ON |

ON |

OFF |

OFF |

10000 |

OFF |

ON |

OFF |

OFF |

20000 |

ON |

OFF |

OFF |

OFF |

40000 |

OFF |

OFF |

OFF |

OFF |

Application

Our JSS86P Integrated Stepper Servo Motor is suitable for various small and medium-sized automated equipment and instruments, such as industrial robots, textile machinery, specialized industrial sewing machines, wire stripping machines, marking machines, cutting machines, laser typesetting systems, plotters, CNC machine tools, engraving machines, and automatic assembly equipment. Particularly effective in applications requiring low noise and high speed.

Custom Service

We provide a variety of customization options in the design, such as output shaft type, connectors, brakes, encoders and gearboxes, etc. Users can flexibly choose according to actual needs. Also can be designed & manufactured with special customized request.

Certificate

We have passed the ISO-9001 quality certification system and obtained a number of application patents. Our products have international certifications such as CE and ROHS.

|

|

|

|

|

|

|

Review

Copyright © 2026 Changzhou Jinsanshi Mechatronics Co., Ltd. All rights reserved. - Privacy policy