Our JSS57P is a type of hybrid servo motor integrated with driver system which has communication function. Using a new generation of 32-bit DSP control technology and closed-loop control technology, it can prevent out-of-step and ensure the accuracy of the product. High-speed torque attenuation is much lower than traditional open-loop drive, which can greatly improve the high-speed performance and torque of stepper motor. Load-based current control technology can effectively reduce motor temperature rise and extend motor life. Built-in position and alarm output signal, convenient for monitoring and control of the host computer. The position error alarm function ensures the safe operation of the processing equipment. It is an ideal upgrade for traditional open-loop stepper drives and can replace some traditional AC servo systems at a price of only 50% of the AC servo system.

1.Features

2.Electrical specifications

Model No. |

Step Angle |

Motor Length |

Current /Phase |

Resistance /Phase |

Inductance /Phase |

Holding Torque |

Encoder lines |

( °) |

(L)mm |

A |

Ω |

mH |

N.m |

No. |

|

JSS57P1.5N |

1.8 |

56 |

4.2 |

0.4

|

1.2 |

1.2 |

1000 |

JSS57P2N |

1.8 |

76 |

4.2 |

0.5 |

1.8 |

2 |

1000 |

JSS57P3N |

1.8 |

112 |

4 |

0.9 |

4.0 |

3 |

1000 |

3.Electrical indicators

Power supply |

Recommended power supply DC36V |

Output current |

Peak 6.0A (current varies with load) |

Logic input current |

10mA~16mA, recommended 10mA |

Pulse frequency |

0~200KHz |

Encoder line number |

1000 |

Insulation resistance |

≥500MΩ |

4.Usage environment and parameters

Cooling method |

Natural cooling or external heat sink |

|

Use environment |

Use occasion |

Try to avoid dust, oil and corrosive gases |

Temperature |

0~40℃ |

|

Humidity |

40~90%RH |

|

Vibration |

5.9m/s2Max |

|

Storage temperature |

-20℃~80℃ |

|

Weight |

About 1.3Kg |

|

5.Interface definition

(1)Power input port

Terminal number |

Symbol |

Name |

Description |

1 |

+Vdc |

DC power positive terminal |

DC+24V~48V Recommended DC+36V power supply |

2 |

GND |

DC power ground |

(2)Control signal port

Terminal number |

Symbol |

Name |

Description |

1 |

PUL+ |

Pulse positive input |

Support 5~24V |

2 |

PUL- |

Pulse negative input |

|

3 |

DIR+ |

Positive input |

|

4 |

DIR- |

Negative input |

|

5 |

ENA+ |

Enable positive input |

|

6 |

ENA- |

Enable negative input |

|

7 |

PEND+ |

In-position signal positive output |

OC gate output, the default closure indicates that the positioning is completed, and the open indication indicates that the positioning is not completed. |

8 |

PEND- |

In-position signal negative output |

|

9 |

ALM+ |

Alarm signal positive output |

OC gate output, the default close indication has an alarm signal, and the open indication indicates no alarm signal. |

10 |

ALM- |

Alarm signal negative output |

(3)RS232 communication port

Terminal number |

Symbol |

Name |

1 |

+5V |

Positive power terminal |

2 |

TXD |

RS232 sender |

3 |

GND |

Power ground |

4 |

RXD |

RS232 receiver |

5 |

NC |

|

(4)Status indication

PWR: Power Indicator. The green indicator lights when power is applied.

ALM: Fault indicator. Red light flashes 1 time within 3 seconds: Over-current or phase-to-phase short-circuit fault; Red light flashes continuously 2 times in 3 seconds: Over-voltage fault; Red light flashes continuously in 7 seconds 7 times: position error tolerance alarm.

6.DIP switch setting

JSS57P uses a six-digit dial switch to set the filter time, motor rotation direction and subdivision accuracy.

SW1, filter time setting. The default on=3ms, off=25ms, the larger the filtering time, the smoother the motor runs and the lower the noise. Moreover, in the on state, the filtering time can be flexibly set by the upper computer software setting.

SW2, motor rotation direction setting. On=CW, off=CCW.

SW3, SW4, SW5, SW6:Subdivision setting

Steps / circle |

SW3 |

SW4 |

SW5 |

SW6 |

default |

ON |

ON |

ON |

ON |

800 |

OFF |

ON |

ON |

ON |

1600 |

ON |

OFF |

ON |

ON |

3200 |

OFF |

OFF |

ON |

ON |

6400 |

ON |

ON |

OFF |

ON |

12800 |

OFF |

ON |

OFF |

ON |

25600 |

ON |

OFF |

OFF |

ON |

51200 |

OFF |

OFF |

OFF |

ON |

1000 |

ON |

ON |

ON |

OFF |

2000 |

OFF |

ON |

ON |

OFF |

4000 |

ON |

OFF |

ON |

OFF |

5000 |

OFF |

OFF |

ON |

OFF |

8000 |

ON |

ON |

OFF |

OFF |

10000 |

OFF |

ON |

OFF |

OFF |

20000 |

ON |

OFF |

OFF |

OFF |

40000 |

OFF |

OFF |

OFF |

OFF |

The default file segmentation defaults to 400, which can be modified by the host computer software.

7.Overall Dimensions

8.Certificate

We have passed the ISO-9001 quality certification system and obtained a number of application patents. Our products have international certifications such as CE and ROHS.

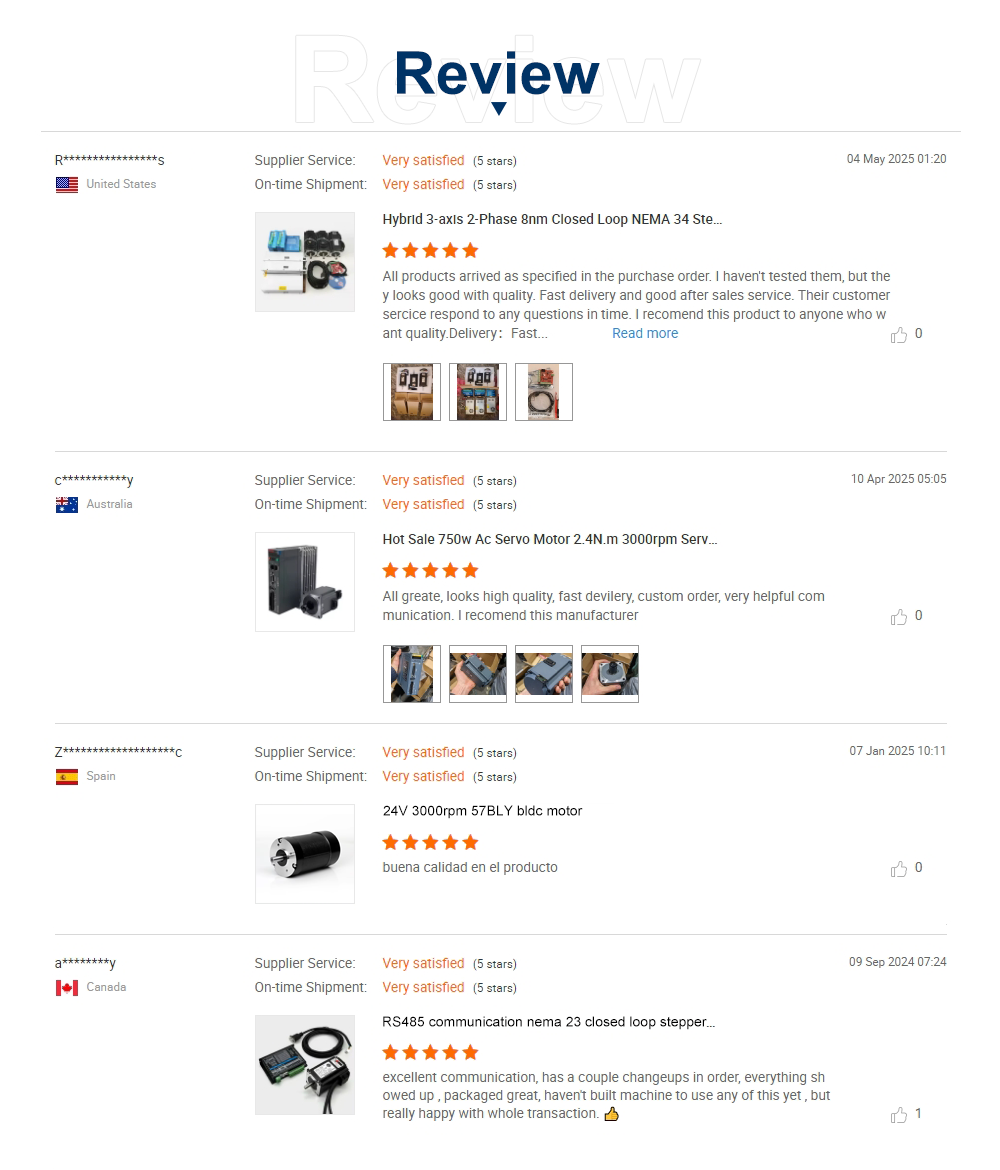

9.Review

Copyright © 2026 Changzhou Jinsanshi Mechatronics Co., Ltd. All rights reserved. - Privacy policy