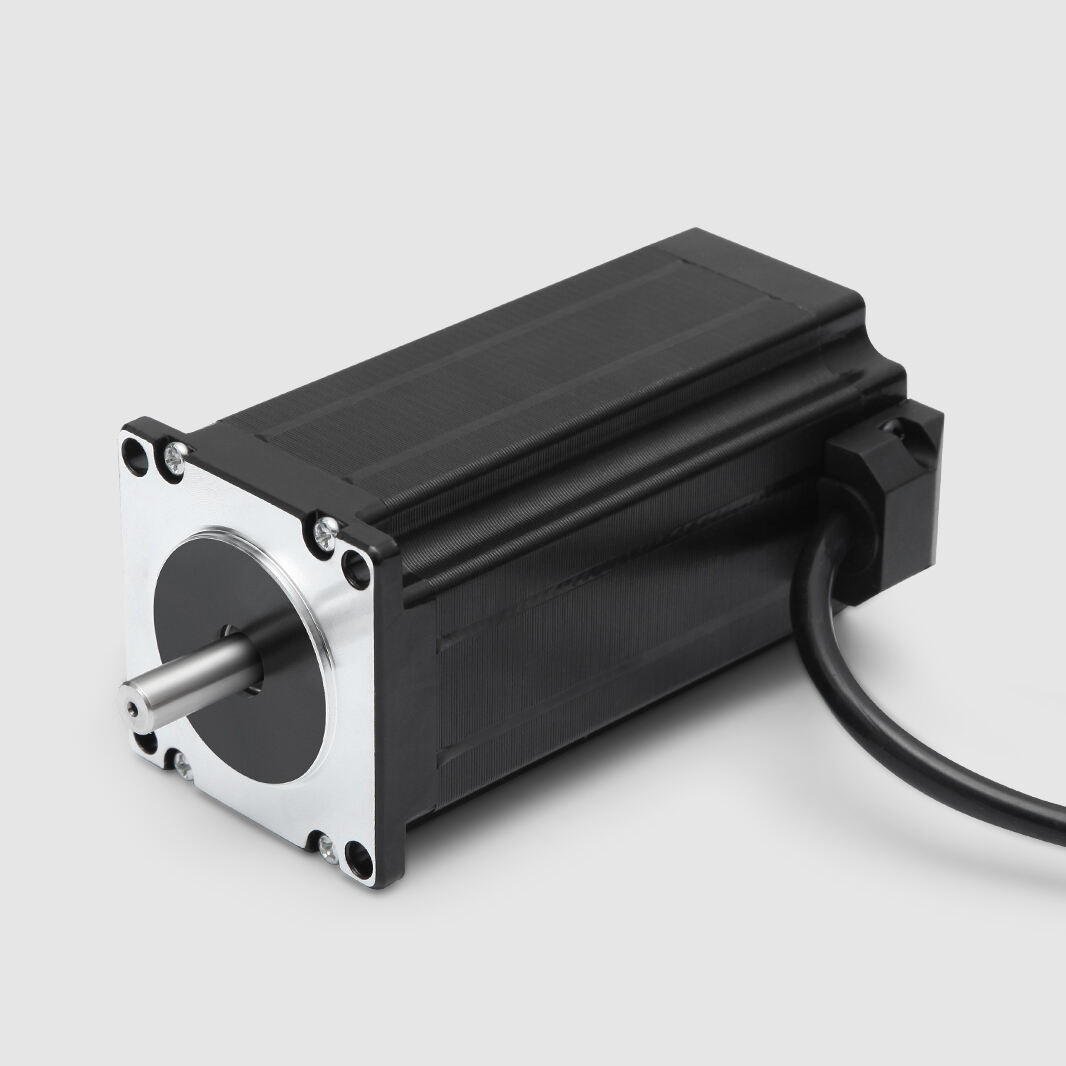

ac and dc servo motor

The AC and DC servo motor are precision devices that convert electrical energy into mechanical rotation with exceptional accuracy and control. Their main function is to provide precise positioning, speed, and torque control in a variety of applications. Technological features of these motors include high efficiency, rapid response to input signals, and the ability to operate over a wide range of speeds and loads. The AC servo motor uses a rotating magnetic field to induce current in the rotor, while the DC servo motor operates with a brushed or brushless commutation system. Applications span across industries from robotics and automation to aerospace and manufacturing, wherever precision and reliability are critical.