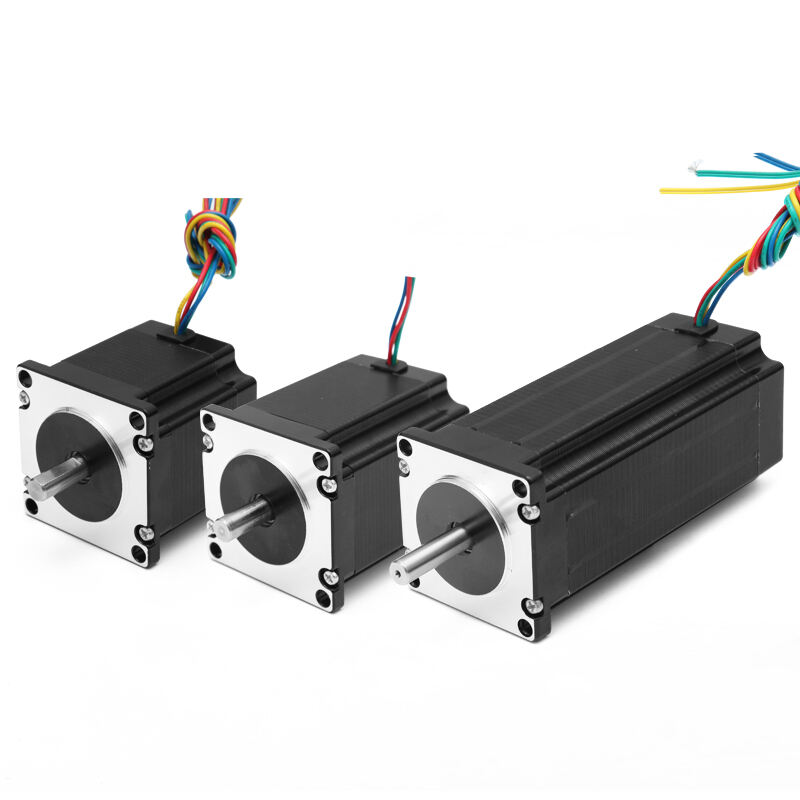

Overview of NEMA 23 Stepper Motors

NEMA 23 stepper motors have become pretty popular because they pack decent power into a small package. Most models feature that standard 2.3 inch square faceplate design which gives them enough strength to handle plenty of different jobs around the shop floor. What makes these motors stand out is how straightforward they are to swap out when needed. The standardized dimensions mean mechanics can quickly replace faulty units without major headaches. This reliability factor explains why so many CNC machine builders and robotics engineers rely on NEMA 23 motors for everything from simple positioning tasks to more complex automation setups where consistent performance matters most.

The motors come with some pretty advanced two phase and hybrid stepper technology built right in, which really boosts their precision and control capabilities. What makes these different from regular old DC motors is how much better they perform when it comes to resolution and smooth operation. They just work so much better for tasks where getting things exactly right matters a lot. Take 3D printing or milling machines for example the way these motors step through each movement gives them an edge in precision that most other systems simply cant match up to. That kind of accuracy makes all the difference in those kinds of applications where even small errors can throw off the whole process.

Constructed with high-quality permanent magnets and diverse winding configurations, NEMA 23 stepper motors can be customized to meet specific operational needs. This flexibility allows for improved efficiency and optimal performance. The various configurations can adapt to different power sources and operation conditions, providing enhanced versatility in automation and robotics.

With holding torque specifications ranging from 1.0 to 3.0 Nm, NEMA 23 stepper motors ensure reliable performance across applications, from light-load robotics to demanding CNC setups. The consistent torque availability helps in maintaining accuracy without sacrificing speed or stability, thereby offering a balanced blend of power and precision.

Common Applications in CNC Machines

Used in Milling Machines, Lathes, and Laser Cutters

NEMA 23 stepper motors are pretty much indispensable for most CNC machines because they deliver both accuracy and consistent torque when needed. When running these machines, even small deviations can ruin complex parts, so having motors that stay on track matters a lot for detailed work in milling operations. What makes these motors stand out is how well they handle torque at slower speeds, something that becomes really important when working with tough materials like steel or titanium in lathes and mills. For laser cutting setups too, NEMA 23 motors help position components just right, resulting in cleaner cuts and less wasted material over time. The level of control these motors provide isn't just nice to have it directly affects how efficiently shops run their operations while maintaining high quality standards across different manufacturing processes.

Provides Precise Positioning for Automated Machining

In automated machining setups, NEMA 23 stepper motors play a key role when it comes to getting those precise positions right, especially since they work alongside sophisticated control systems featuring various feedback mechanisms. What makes these motors stand out is their microstepping feature, which lets operators control movements at much finer levels than standard stepping allows. This translates into better accuracy overall and smoother surface finishes on manufactured parts. Because of this high level of resolution and repeatable performance, manufacturers can count on consistent results across entire production batches meeting even the toughest quality specs. The fact that so many shops depend on these motors speaks volumes about how critical they are for keeping things accurate enough to produce quality products while still running operations efficiently day after day.

Role in 3D Printing

Controls Extruder Movement and Print Bed Positioning

When it comes to 3D printing, NEMA 23 stepper motors are pretty much the backbone of what makes good prints happen. They handle both the extruder movement and control over the print bed, which means layers get deposited exactly where they need to be. Without this kind of motor power, we'd see all sorts of issues creeping into our prints. These motors keep things moving consistently so mistakes don't happen too often, which cuts down on those frustrating defective parts everyone hates. What makes them stand out is how well they work with different types of filament materials. Whether someone's printing with PLA or something trickier like nylon, these motors can tweak their speed and flow rate accordingly. That flexibility helps maintain that important level of detail in finished prints. For anyone serious about getting reliable results from their 3D printer, investing in quality NEMA 23 motors really pays off in the long run.

Ensures High Accuracy in Layer Deposition

NEMA 23 stepper motors play a key role in keeping layer deposition accurate when creating 3D models. When layers aren't deposited properly, details get lost in the print. These motors help maintain consistent layer thickness throughout the build process. What really sets them apart is their ability to do microstepping, which allows for much finer control over movement. This matters a lot when printing intricate shapes or tight curves that require precise positioning. With advancements happening all the time in 3D printing tech, manufacturers continue to rely on this motor type because they simply deliver better results than alternatives. Many prototyping shops have switched to NEMA 23 motors after seeing improvements in surface finish and dimensional accuracy across various materials.

Applications in Robotics

Used in Robotic Arms and Autonomous Vehicles

NEMA 23 stepper motors form the backbone of many robotic arms and self-driving cars on the market today. What makes these motors so important? They deliver just enough power and fine-tuned speed control to let robotic arms perform their programmed tasks accurately. Think about manufacturing plants where robots need to put together intricate parts or handle fragile components without damaging them. That kind of pinpoint accuracy comes straight from NEMA 23 motors. When we look at autonomous vehicles, these same motors become critical for steering mechanisms and drive systems. They allow vehicles to react quickly when road conditions change suddenly. The best part? These motors don't break down often and require minimal upkeep. For manufacturers looking to keep production lines running smoothly, this reliability means fewer unexpected shutdowns and better overall productivity across different applications.

Enables Controlled and Repeatable Movements

NEMA 23 stepper motors have really good control over their movements, which is why they work so well for tasks that need to be done again and again in automated systems and robots. When paired with the right controller board, these motors follow programmed instructions pretty accurately most of the time, keeping things running smoothly day after day. Precision matters a lot in certain situations, such as when robotic arms grab components from one spot and place them somewhere else on an assembly line. The fact that these motors can move the same way every single time helps factories keep producing at high speeds while still meeting quality standards. For manufacturers dealing with tight tolerances and fast production cycles, this kind of repeatability just makes sense both operationally and economically.

Use in Automated Manufacturing Equipment

Drives Conveyor Systems, Pick-and-Place Machines, and Textile Machinery

NEMA 23 stepper motors are now indispensable in automated manufacturing setups, driving everything from conveyor belts to those little pick-and-place robots we see on assembly lines, plus all sorts of textile machines too. When it comes to conveyor systems specifically, these motors really shine at keeping materials moving smoothly through factories without hiccups, which helps keep production flowing consistently. For pick-and-place applications, their accuracy matters a lot since they need to grab tiny components and place them exactly where needed without messing things up. Textile manufacturers have also found value in NEMA 23 motors for tasks like sewing and fabric cutting operations. The speed and control these motors provide makes all the difference when trying to hit those tight production targets while still maintaining quality standards across batches.

Enhances Efficiency in Industrial Automation

NEMA 23 stepper motors have become essential components in industrial automation systems, going well beyond just controlling motion. These motors allow machines to operate reliably and accurately, which means factories can produce goods faster while wasting less material during the process. The technology also makes it easier to incorporate sophisticated automation features, cutting down on the need for workers to perform repetitive manual tasks day after day. What's really interesting is how these motors enable manufacturers to build modular equipment that can be quickly reconfigured when production needs change. A factory might switch from making one type of component to another within hours simply by adjusting the motor settings. This flexibility has made NEMA 23 steppers a go-to choice for many plants looking to stay competitive in markets where customer demands constantly shift.

Applications in Medical Devices

Applied in Lab Equipment, Fluid Pumps, and Imaging Systems

Medical devices rely heavily on NEMA 23 stepper motors because they offer both precision and dependability. Labs across the country use these motors all the time for automating delicate procedures, especially when handling tiny sample volumes during testing. The motors can move components back and forth repeatedly without losing accuracy, something labs need day after day for consistent results. When we look at fluid pumps used in various medical contexts, these motors really shine too. They control how much liquid moves through tubes with amazing accuracy, critical for things like drug delivery systems where even small errors matter a lot. Even in imaging equipment, NEMA 23 motors play an important role. Their precise positioning capabilities help create clearer images, whether it's MRI scans or X-rays, ultimately leading to better diagnoses for patients. Many technicians actually prefer working with these motors because they just work so reliably over long periods.

Provides Precise Control in Critical Applications

In medical settings where things need to work right every time, NEMA 23 stepper motors bring exactly what's needed. These motors keep medical equipment running smoothly day after day, giving doctors and nurses the precision they rely on for important procedures. What makes them stand out is how durable they are plus minimal upkeep requirements, which matters a lot when hospitals can't afford downtime. From MRI machines to patient monitors, these motors help power through daily operations without breaking a sweat. As healthcare technology continues evolving, having reliable components like NEMA 23 motors becomes even more crucial for meeting today's high standards in patient care.

Conclusion

NEMA 23 stepper motors play a big role across many different industries because they deliver really good precision and reliability when accuracy matters most. Take CNC machining for instance where tiny details need to be repeated over and over again, or look at medical devices that must operate with extreme care. These motors give the kind of control needed for such delicate work. Built tough from the start, they keep performing reliably even after years of use, which explains why so many manufacturers rely on them day in and day out.

NEMA 23 stepper motors bring something special to the table for manufacturers across many industries. Their ability to work well in so many different situations means machines can do more than just basic functions. We see these motors everywhere now, powering everything from factory assembly lines right down to precision instruments used in hospitals. The real value comes when companies realize how much better their equipment performs with these motors installed. For example, some medical device makers report faster response times and greater accuracy in their diagnostic tools since switching to NEMA 23 technology. As industries continue looking for ways to improve efficiency without breaking the bank, these versatile motors keep finding new roles that push what's possible in modern manufacturing.

FAQ

What are NEMA 23 stepper motors used for?

NEMA 23 stepper motors are used in various applications, including CNC machines, 3D printing, robotics, automated manufacturing equipment, medical devices, and surveillance systems, due to their precision and reliability.

What is the torque range of NEMA 23 stepper motors?

The holding torque specifications for NEMA 23 stepper motors range from 1.0 to 3.0 Nm, ensuring reliable performance across different applications.

What makes NEMA 23 stepper motors suitable for CNC machines?

NEMA 23 stepper motors offer precision and reliable torque output, making them ideal for CNC machines, as they help maintain accuracy and minimize deviations during operations.