Overview of NEMA 23 Stepper Motors and Their Applications

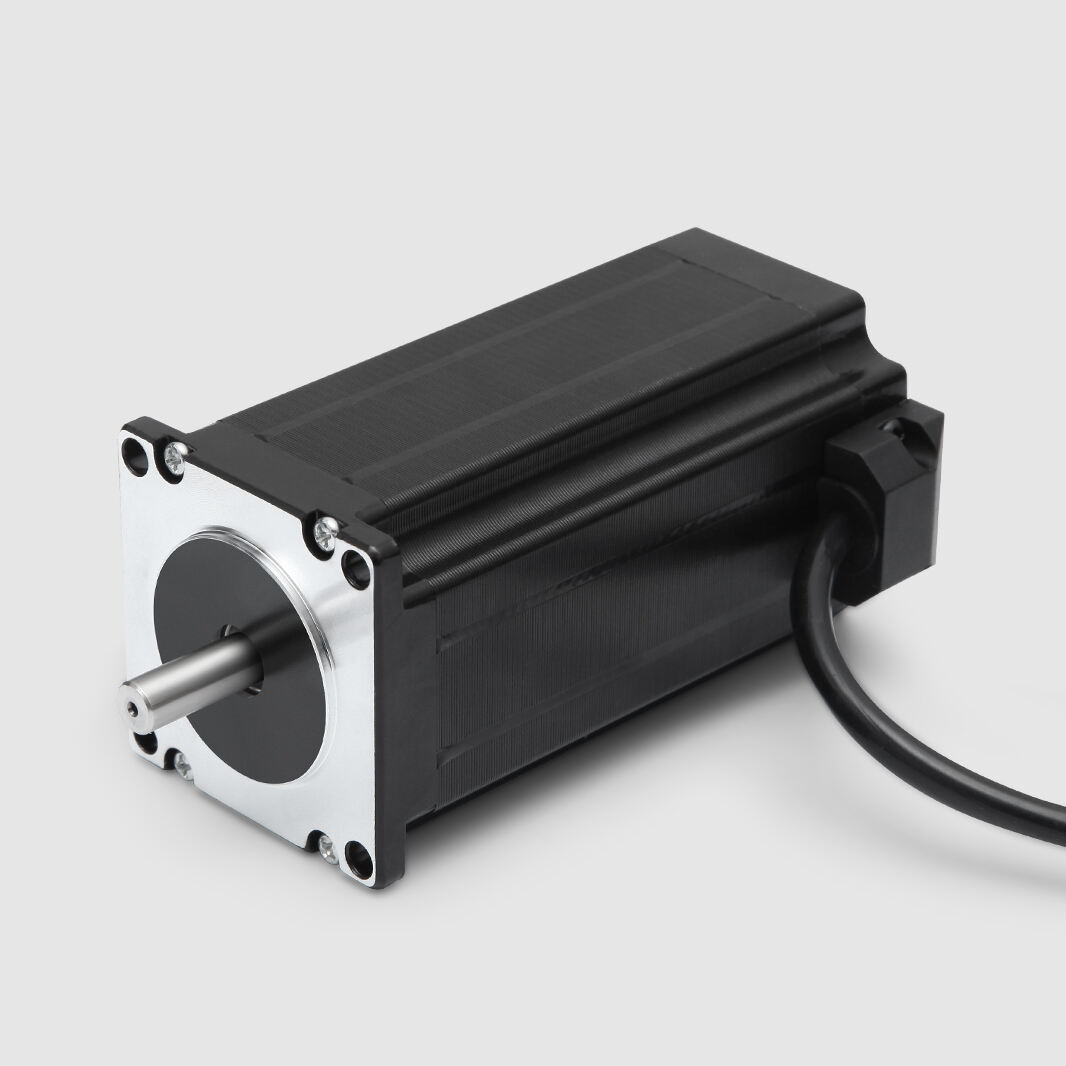

The NEMA 23 stepper motor gets a lot of praise for how accurately it controls movement, which makes these motors really useful across different engineering projects and robot designs. What sets them apart is that they follow standard size specifications set by the National Electrical Manufacturers Association (NEMA). This means engineers can plug them into all sorts of tech setups without major headaches over fitting issues. The benefits become especially clear when looking at things like 3D printers, computer controlled cutting machines, and robotic arms where getting the motion just right matters a ton. Take a CNC machine for example the way it handles angles determines whether it cuts metal or plastic properly every single time it runs.

When looking at design specs, NEMA 23 stepper motors get evaluated mainly through three key factors: step angle, current rating per phase, and how much torque they can hold when stopped. Most models come with a standard step angle around 1.8 degrees, meaning they take about 200 steps to complete one full rotation. This allows pretty good control over movement precision. These motors show up everywhere now - from hobbyist 3D printers all the way up to sophisticated robotic arm systems in factories. People really like them because they work well across so many different situations and tend to be pretty dependable over time. Their presence in both small scale projects and large manufacturing setups highlights why engineers keep coming back to them for tasks needing exact positioning. The level of control these motors provide has become essential in today's tech driven world where accuracy matters most.

Frame Size and Dimensions of NEMA 23 Stepper Motors

Standard NEMA 23 Size: 56.4mm x 56.4mm

NEMA 23 stepper motors typically measure around 56.4mm on each side, giving them their distinctive square faceplate shape. This standard sizing makes these motors work well with most mounting systems out there. For engineers working on designs, having this common dimension really helps streamline the whole setup process since everyone knows what they're dealing with. Getting the exact measurements right matters because otherwise the motor won't fit properly into whatever system it needs to go into. That affects both how easy it is to install and how well it performs once running, especially important stuff like robotic arms or CNC machinery where precision counts. The square faceplate isn't some random design decision either. It actually plays a key role in whether the motor lines up correctly with whatever components need to connect to it during operation.

Variations in Length and Their Impact on Torque and Power

The NEMA 23 stepper motor comes in various lengths, and these different sizes really affect how much torque and power they deliver. Longer motors tend to generate more torque, something that matters a lot when tackling tough jobs like drilling through thick materials on a CNC machine or controlling fine movements in robotic arms. Anyone working with these motors needs to understand how changing the length affects things like torque output before picking out the right one for their particular setup. When engineers match the motor size to what the job actually requires, they get better performance overall. This makes sure the motor works properly without overworking or underperforming for whatever application it ends up in.

Step Angle and Resolution in NEMA 23 Stepper Motors

Common Step Angles: 1.8° and 0.9°

NEMA 23 stepper motors come in two main varieties when it comes to step angles: most commonly 1.8 degrees or half that at 0.9 degrees. The bigger 1.8 degree version takes 200 steps to complete one full turn around, whereas the smaller 0.9 degree model needs double that number, 400 steps, for the same rotation. What does this actually mean? Well, the difference in these step sizes has a real impact on how finely we can control movement. Smaller steps allow much better precision which is exactly what many modern machines need. Take 3D printers for instance they rely heavily on those tiny increments to create detailed prints layer by layer. Similarly robots working on assembly lines benefit greatly from being able to position components with pinpoint accuracy instead of just approximate guesses.

How Step Angle Affects Precision and Smoothness

The step angle matters just as much as resolution when it comes to how well a motor performs. Motors that have smaller step angles around 0.9 degrees tend to run smoother because they take more steps during each full rotation. The difference really shows up in situations where things need to move precisely without jerking around. Think about those automated inspection systems that check tiny components for defects they absolutely need that kind of smooth motion. For anyone picking out a NEMA 23 motor for their project, getting familiar with how step angle affects actual performance makes all the difference. It's not just theory stuff this knowledge helps pick the right motor for jobs where accuracy simply cannot be compromised.

Holding Torque Specifications of NEMA 23 Stepper Motors

Typical torque range: 0.5 Nm to 3 Nm

NEMA 23 stepper motors generally offer holding torques somewhere between 0.5 Newton meters and 3 Newton meters depending on the model. What makes this feature so valuable is that it keeps the motor locked in place even when power isn't running through it, which stops accidental shifts or drifts. For things like 3D printing heads or CNC routers where exact positioning matters, this kind of stability ensures parts come out right every time. When engineers look at these torque specs during design phase, they get a good sense of whether the motor will stand up under different workloads throughout its operation cycle. That's why manufacturers pay close attention to these numbers especially in high precision manufacturing environments where even minor deviations can lead to quality issues down the line.

Higher torque motors for demanding applications like CNC machines

When working on high performance applications like CNC machining centers or industrial robots, going for NEMA 23 stepper motors with better torque specs becomes really important. These particular motors are built tough enough to manage heavy workloads without locking up mid-operation, which means they run smoother and last longer in practice. The key thing for engineers is matching the right amount of torque to what the machine actually needs. Getting this right helps pick the best motor for the job, making sure everything runs efficiently while extending how long the equipment stays functional. Proper motor selection makes all the difference in day to day operations too. It cuts down on breakdowns, saves money over time, and ultimately creates a manufacturing setup that works better without breaking the bank.

Current and Voltage Ratings of NEMA 23 Stepper Motors

Importance of Matching Power Supply with Motor Requirements

Getting the right power supply for a NEMA 23 stepper motor makes all the difference when it comes to how well it works and staying safe during operation. When the amps and volts from the power source line up with what the motor needs, things run smoothly without wasting energy or risking damage. If these specs don't match up properly, problems start showing up fast. Motors might overheat or just plain underperform, which means they won't last as long as expected and could bring down entire systems unexpectedly. Anyone working with these motors should take time to figure out exactly what kind of electrical demands they have and where their limits lie. Matching components correctly not only saves money on wasted electricity but also keeps equipment running reliably day after day without surprises.

Common Current Ratings from 2A to 4A per Phase

Most NEMA 23 stepper motors work within a current range of around 2A to 4A per phase. This current window really affects how much torque the motor can produce and how it handles heat buildup during operation. Getting the right current rating matters when building those driver circuits and setting up proper cooling solutions. Tweak these settings properly and the motor will deliver better torque while running smoothly through different applications like automated manufacturing lines or robotics systems. When engineers pay attention to these specs, they match what the motor can do with what the job actually needs, making everything fit together better and run more efficiently in practice rather than just on paper.

Shaft and Mounting Specifications of NEMA 23 Stepper Motors

Standard Shaft Diameter (e.g., 6.35mm or 8mm)

NEMA 23 stepper motors come with standard shaft sizes most commonly at 6.35mm or 8mm across the industry. These measurements matter quite a bit because they decide whether the motor will work properly with different kinds of gears and other attachments. Anyone working on engineering projects really needs to know about these shaft specs when putting together mechanical systems. Getting the right shaft size makes sure everything fits together correctly without problems down the road. Wrong sizing can lead to all sorts of headaches later on like things not aligning properly or parts just not fitting at all which nobody wants in their design project.

Compatibility with Couplings and Mounting Brackets

Getting motor performance right starts with knowing the mounting specs that work together, things like flange patterns and different shaft types. When couplings and brackets fit properly, NEMA 23 stepper motors actually run better in real world applications. Engineers who take time to check these details find they can pick the correct accessories without headaches later on. The payoff comes from smoother installation into current setups. Beyond just making things work today, proper compatibility means motors last longer too. Misaligned parts wearing out prematurely becomes less of a problem when everything matches up correctly from the start.

Conclusion

Understanding what specs matter most when working with NEMA 23 stepper motors makes all the difference for engineers and designers trying to pick the right motor for their projects. When someone knows exactly what they need in terms of torque, how many steps per revolution the motor can handle, and its electrical characteristics, they're able to match motors to actual application demands much better. Take step angle and holding torque as two critical factors. A motor with too small a step angle might not provide enough resolution for certain tasks, while insufficient holding torque could lead to positioning errors during operation. Getting these details right upfront saves time and money down the road by avoiding mismatched components.

Getting the right match between motor specs and their corresponding drivers plus power supplies makes a big difference in how well systems actually perform day to day. When everything works together properly, equipment runs smoother which means less time spent fixing breakdowns and lower bills for repairs. Mismatched parts tend to wear out faster too, so getting this right from the start saves money long term. Industrial facilities especially need reliable operation since production lines cant afford unexpected stoppages. Engineers who take care to check compatibility upfront typically see better results across the board, both in terms of energy savings and reduced risk of sudden failures during critical operations.

FAQ

What are the advantages of using NEMA 23 stepper motors in CNC machines?

NEMA 23 stepper motors are advantageous in CNC machines due to their precision and ability to manage angular positions accurately, which is essential for cutting materials with accuracy and repeatability.

How does the length of a NEMA 23 stepper motor affect its torque and power?

The length impacts torque and power; longer motors generally deliver higher torque, making them suitable for demanding tasks like heavy-duty drilling in CNC machines.

Why is matching the power supply important for NEMA 23 stepper motors?

Matching the power supply ensures that the current and voltage ratings align with the motor's, preventing inefficiencies, potential damage, and overheating while enhancing system reliability.

What is the role of step angle in NEMA 23 stepper motors?

The step angle determines the number of steps per revolution, affecting the resolution and precision of motionâkey factors in applications requiring exact positioning like 3D printing.

What are bipolar and unipolar configurations in NEMA 23 stepper motors?

Bipolar configurations use a 4-wire setup and provide better torque by utilizing all windings, while unipolar, with 6 or 8 wires, offer simpler wiring and may suit specific applications better.

Table of Contents

- Overview of NEMA 23 Stepper Motors and Their Applications

- Frame Size and Dimensions of NEMA 23 Stepper Motors

- Step Angle and Resolution in NEMA 23 Stepper Motors

- Holding Torque Specifications of NEMA 23 Stepper Motors

- Current and Voltage Ratings of NEMA 23 Stepper Motors

- Shaft and Mounting Specifications of NEMA 23 Stepper Motors

- Conclusion

-

FAQ

- What are the advantages of using NEMA 23 stepper motors in CNC machines?

- How does the length of a NEMA 23 stepper motor affect its torque and power?

- Why is matching the power supply important for NEMA 23 stepper motors?

- What is the role of step angle in NEMA 23 stepper motors?

- What are bipolar and unipolar configurations in NEMA 23 stepper motors?