Our JSS42P is a type of hybrid servo motor integrated with driver system which has communication function. Using a new generation of 32-bit ARM control technology and closed-loop control technology can prevent lose step and ensure product accuracy; The high-speed torque attenuation is much lower than that of traditional open-loop drivers, which can greatly improve the high-speed performance and torque of the stepper motor; The latest current control technology based on the current can effectively reduce the temperature rise of the motor and extend the service life of the motor; The built-in position in-place and alarm output signals facilitate monitoring and control by the upper computer; the position out-of-tolerance alarm function ensures the safe operation of the processing equipment. It is an ideal upgrade product for traditional open-loop stepper drivers, and can replace some traditional AC servo systems, and the price is only 50% of AC servo systems. Our JSS42P integrated stepper

1.Features

2.Electrical indicators

Input voltage |

DC24V |

Output current |

peak 2.5A (changes with load) |

Logic input current |

7~ 16mA, recommend 10mA |

Pulse frequency |

0~200KHz |

Encoder resolution |

1000 |

Insulation resistance |

≥500MΩ |

3.Usage environment and parameters

Cooling type |

Natural cooling or external radiator |

|

Usage environment |

Use occasions |

Try to avoid dust, oil and corrosive gases |

Temperature |

0~40℃ |

|

Humidity |

40~90%RH |

|

Vibration |

5.9m/s²Max |

|

storage temperature |

-20℃~80℃ |

|

Weight |

About 0.5Kg |

|

4.Interface definition

(1)Power input port

Pin No |

Symbol |

Name |

Description |

1 |

+Vdc |

DC power supply positive terminal |

DC+24V input |

2 |

GND |

DC power ground |

|

3~6 |

NC |

(2)Control signal port

Pin No |

Symbol |

Name |

Description |

1 |

PU+ |

Pulse positive input |

Accept 5V |

2 |

PU- |

Pulse negative input |

|

3 |

DR+ |

Direction positive input |

|

4 |

DR- |

Direction negative input |

|

5 |

MF+ |

Enable positive input |

|

6 |

MF- |

Enable negative input |

|

7 |

ALM+ |

Alarm signal positive output |

OC door output, default closed indicates an alarm signal, open circuit indicates no alarm signal. |

8 |

ALM- |

Alarm signal negative output |

(3)Status indication

PWR: power indicator light. When power is on, the green indicator light is on.

ALM: fault indicator light. Flashing red light once within 3 seconds: over-current or phase-to-phase short circuit fault; Flashing red light 2 times continuously within 3 seconds: over-voltage fault; Flashing red light 7 times continuously within 3 seconds: position error alarm.

5.DIP switch setting

JSS42P uses a five-digit DIP switch to set the motor rotation direction and subdivision accuracy.

SW1: motor rotation direction setting. on=CW, off=CCW.

SW2, SW3, SW4, SW5: Subdivision settings.

Pulse/Rev |

SW2 |

SW3 |

SW4 |

SW5 |

400 |

ON |

ON |

ON |

ON |

800 |

OFF |

ON |

ON |

ON |

1600 |

ON |

OFF |

ON |

ON |

3200 |

OFF |

OFF |

ON) |

ON |

6400 |

ON |

ON |

OFF |

ON |

12800 |

OFF |

ON |

OFF |

ON |

25600 |

ON |

OFF |

OFF |

ON |

51200 |

OFF |

OFF |

OFF |

ON |

1000 |

ON |

ON |

ON |

OFF |

2000 |

OFF |

ON |

ON |

OFF |

4000 |

ON |

OFF |

ON |

OFF |

5000 |

OFF |

OFF |

ON |

OFF |

8000 |

ON |

ON |

OFF |

OFF |

10000 |

OFF |

ON |

OFF |

OFF |

20000 |

ON |

OFF |

OFF |

OFF |

40000 |

OFF |

OFF |

OFF |

OFF |

This subdivision number can be modified by the upper computer software.

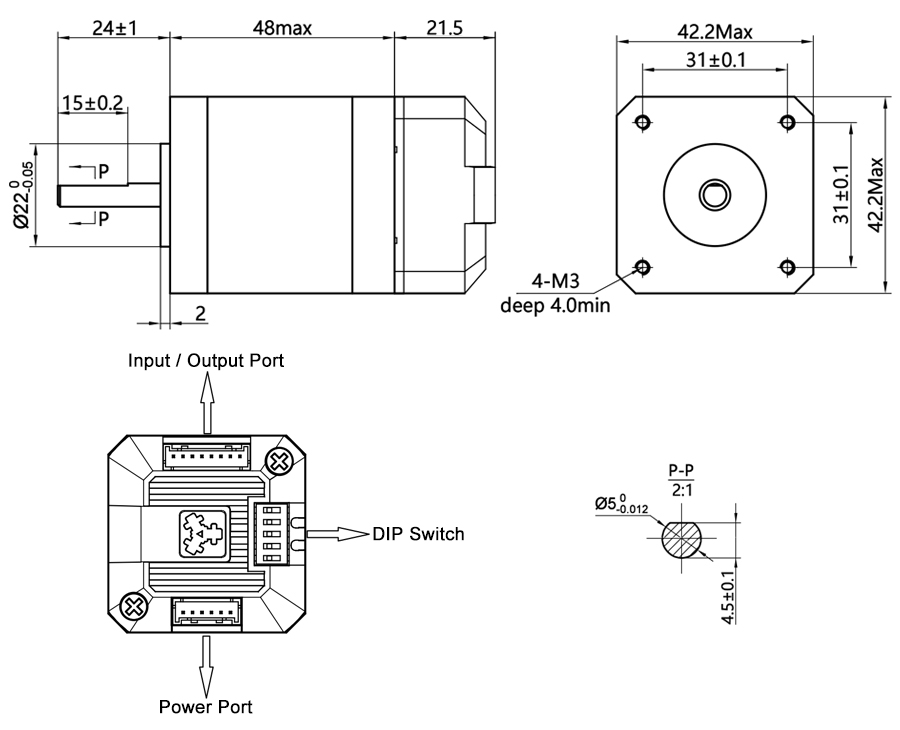

6.Overall Dimensions

7.Certificate

We have passed the ISO-9001 quality certification system and obtained a number of application patents. Our products have international certifications such as CE and ROHS.

8.Review

Copyright © 2026 Changzhou Jinsanshi Mechatronics Co., Ltd. All rights reserved. - Privacy policy