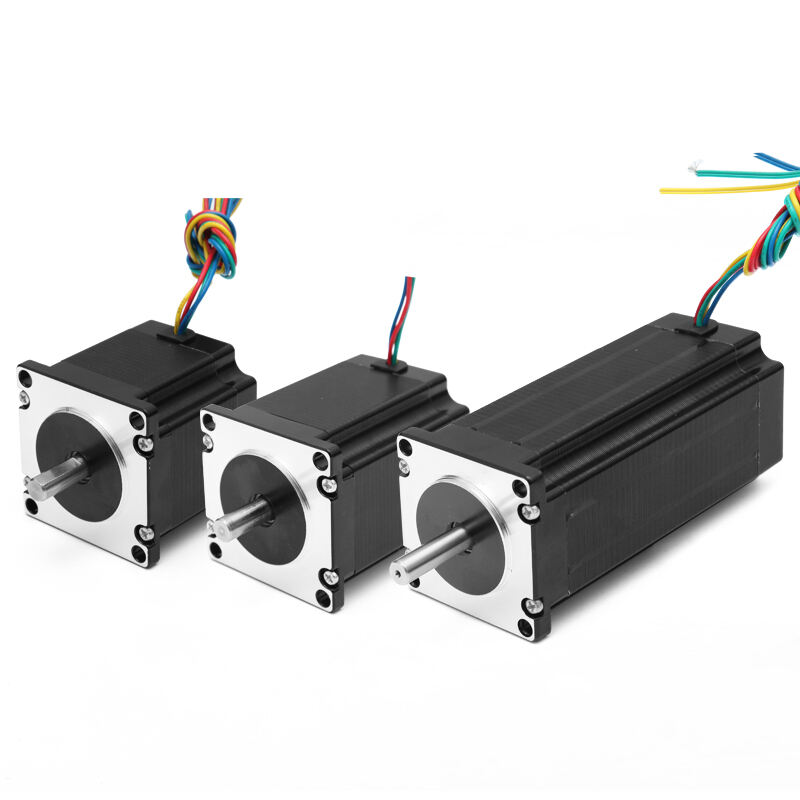

Apžvalga apie NEMA 23 žingsnių variklius

NEMA 23 žingsniniai varikliai įgijo gana didelio populiarumo, nes jie siūlo pakankamai galią mažame korpuso korpuse. Daugelio modelių konstrukcijoje yra standartinis 2,3 colio kvadratinis priekinis skydelis, kuris suteikia pakankamai jėgos atlikti įvairias užduotis gamybos patalpose. Šių variklių išskirtinė savybė yra paprastumas, kai reikia juos pakeisti. Standartiniai matmenys leidžia technikams greitai pakeisti sugedusius vienetus be didelių sunkumų. Būtent ši patikimumo savybė paaiškina, kodėl tiek daug CNC staklių kūrėjų ir robototechnikos inžinierių pasikliauja NEMA 23 varikliais – tiek papratosioms pozicionavimo užduotims, tiek sudėtingesnėse automatizacijos sistemose, kur svarbiausia yra nuolatinis našumas.

Varikliuose jau įdiegta gana pažangi dviejų fazių ir hibridinė žingsninė technologija, kuri tikrai padidina jų tikslumą ir valdymo galimybes. Tai, kas skiria šiuos variklius nuo įprastų nuolatinės srovės variklių, yra jų geresnis našumas, kalbant apie skiriamąją gebą ir sklandžią veiklą. Jie tiesiog geriau veikia užduotims, kur svarbu viską atlikti kuo tiksliau. Paimkime, pavyzdžiui, 3D spausdintuvus ar frezavimo mašinas – šių variklių judesių tikslumas suteikia jiems pranašumą, kurio daugelis kitų sistemų negali pasiekti. Toks tikslumas yra labai svarbus tose srityse, kur net menkiausios klaidos gali sutrikdyti visą procesą.

Sukurta iš aukštos kokybės pastovinių magnetų ir įvairių apdengimo konfigūracijų, NEMA 23 žingsnio varikliai gali būti pritaikyti pagal specifines eksploatacijos reikalavimus. Ši flexibilumas leidžia pagerinti efektyvumą ir užtikrinti optimalią našumą. Įvairios konfigūracijos gali pritaikytis prie skirtingų jėgos šaltinių ir eksploatacijos sąlygų, suteikiant didesnį verslumo lygį automatysoje ir robotikoje.

Su momentu, kuris kinta nuo 1,0 iki 3,0 Nm, NEMA 23 žingsnio varikliai užtikrina patikimą veikimą įvairiose programose – nuo lengvų robotikos sistemų iki griežtų CNC montažo schemų. Stabilus momentas padeda išlaikyti tikslumą, neprarandant greičio ar stabilumo, taip suteikiant pusiausvyringą jėgos ir tikslumo derinį.

Populiarios programos CNC mašinose

Naudojamos frazežuose, torniuose ir laseriniuose pjovimuose

NEMA 23 žingsniniai varikliai yra beveik būtini daugelyje CNC mašinų, nes jie užtikrina tikslumą ir pastovų sukiojantį momentą, kai jis reikalingas. Kai šios mašinos veikia, net menkiausios paklaidos gali sugadinti sudėtingas dalis, todėl variklių, kurie išlaiko tikslų judėjimą, svarba detaliam darbui frezavimo operacijose yra labai didelė. Tai, kas išskiria šiuos variklius, yra jų gebėjimas tvarkingai valdyti sukiojantį momentą esant lėtesniam judėjimui, o tai tampa ypač svarbu dirbant su sunkiai apdirbamu metalu, tokiu kaip plienas ar titanas, naudojant gręžtuvus ir frezavimo mašinas. Taip pat lazerio pjaustymo konfigūracijoms NEMA 23 varikliai padeda tiksliai pozicionuoti komponentus, todėl pjaustymas yra švaresnis ir mažiau iššvaistoma medžiagos per tam tikrą laiką. Valdymo lygis, kurį šie varikliai suteikia, nėra tik papildomas privalumas – jis tiesiogiai veikia gamybos įmonių veiklos efektyvumą, kartu užtikrindamas aukšto lygio kokybę per įvairius gamybos procesus.

Tikslus padėties nustatymas automatizuotam gaminiui

Automatizuotuose apdirbimo įrenginiuose NEMA 23 žingsniniai varikliai svarbūs siekiant tikslaus pozicionavimo, ypač dirbant kartu su sudėtingomis valdymo sistemomis, turinčiomis įvairių grįžtamąjį ryšį užtikrinančių mechanizmų. Šių variklių ypatingumas – mikrožingsnių funkcija, leidžianti operatoriams valdyti judėjimus kur kas smulkesniais etapais nei leidžia standartinė žingsniavimo sistema. Tai padeda pasiekti geresnį tikslumą ir lygesnes pagamintų detalių paviršių būklę. Dėl šio aukšto tikslumo ir kartojimo patikimumo gamintojai gali pasikliauti nuosekliais rezultatais visose gamybos partijose, atitinkančiomis net griežčiausius kokybės reikalavimus. Faktas, kad daugelis įmonių pasikliauja šiais varikliais, byloja apie jų svarbą užtikrinant pakankamą tikslumą, reikalingą kokybiškai produkcijai gaminti, o tuo pačiu leidžianti efektyviai valdyti kasdienes operacijas.

Vaidmuo 3D spaudimo procese

Valdo ekstruderio judėjimą ir spaudos platformos padėtį

Kai kalbama apie 3D spausdintuvus, NEMA 23 žingsniniai varikliai yra beveik pagrindinė konstrukcijos dalis, leidžianti gauti kokybiškus spausdintus objektus. Jie valdo tiek ekstruderio judėjimą, tiek spausdintuvo plokštės judėjimą, todėl sluoksniai yra dedami tiksliai ten, kur reikia. Be tokio variklių naudojimo, spausdintuose objektuose atsirastų įvairių defektų. Šie varikliai užtikrina nuoseklų judėjimą, todėl klaidos pasitaiko retai, mažėja nereikalingų, klaidingų dalių skaičius, kurie visiems nepatinka. Jų privalumas yra tas, kad jie puikiai veikia su įvairių tipų filamento medžiagomis. Ar tai būtų PLA ar sudėtingesnė medžiaga kaip nilonas, šie varikliai gali pritaikyti judėjimo greitį ir filamento padavimo intensyvumą. Toks lankstumas padeda išlaikyti svarbų detalės lygį galutiniuose spausdintuose objektuose. Tiems, kas rimtai rūpinasi dėl 3D spausdintuvo patikimumo ir rezultatų, kokybiškų NEMA 23 variklių įsigijimas išsimoka ilgalaikėje perspektyvoje.

Užtikrina aukštą sluoksnių depozicijos tikslumą

NEMA 23 žingsniniai varikliai svarbūs spausdinant 3D modelius, nes jie užtikrina sluoksnių tikslų nešiojimą. Kai sluoksniai nėra tinkamai dedami, detalės prarandamos spausdinant. Šie varikliai padeda išlaikyti nuoseklų sluoksnių storį visą gamybos procesą. Tai, kas išskiria šiuos variklius, yra jų gebėjimas atlikti mikrožingsnius, kurie leidžia tiksliau valdyti judėjimą. Tai ypač svarbu spausdinant sudėtingas formas arba glaudžius lankstus, kuriems reikia tikslaus pozicionavimo. Nuo to, kad 3D spausdinimo technologijoje nuolat vyksta pažanga, gamintojai ir toliau pasikliauja šiuo variklių tipu, nes jie tiesiogiai suteikia geresnius rezultatus nei alternatyvos. Daugelis prototipų dirbtuvių pereina prie NEMA 23 variklių, pastebėjusios pagerėjimą paviršiaus apdorojime ir matmenų tikslumo įvairiomis medžiagomis.

Taikymai robotikoje

Naudojami robotiniuose rankų ir automatinėse transporto priemonėse

NEMA 23 žingsniniai varikliai sudaro daugelio robotų rankų ir automobilių be vairuotojo pagrindą, esančią šiandieninėje rinkoje. Kodėl šie varikliai yra tokie svarbūs? Jie suteikia pakankamai galią ir tikslų greičio valdymą, kuris leidžia robotų rankoms tiksliai atlikti jų suprogramuotus darbus. Įsivaizduokite gamybos įmones, kuriose robotai turi surinkti sudėtingas dalis arba tvarkyti trapius komponentus, kad jie nenukentėtų. Toks tikslumas tiesiogiai priklauso nuo NEMA 23 variklių. Nagrinėjant autonominius automobilius, šie patys varikliai tampa kritiškai svarbūs vairavimo mechanizmams ir varomosioms sistemoms. Jie leidžia automobiliams greitai reaguoti, kai kelių sąlygos netikėtai pasikeičia. Geriausia yra tai, kad šie varikliai retai sugenda ir reikalauja minimalaus priežiūros. Gamintojams, siekiantiems užtikrinti sklandžią gamybos linijų veiklą, tokia patikimumo savybė reiškia mažiau netikėtų sustojimų ir geresnį visų srities našumą.

Leidžia kontroliuojamus ir pakartojamus judėjimus

NEMA 23 žingsniniai varikliai turi labai gerą judesių kontrolę, todėl jie puikiai tinka užduotims, kurios daug kartų kartojamos automatizuotuose sistemose ir robotuose. Kartu su tinkama valdymo plokšte, šie varikliai dažnai tiksliai vykdo suprogramuotas instrukcijas, užtikrindami sklandžią veiklą iš dienos į dieną. Tikslumas yra labai svarbus tam tikrose situacijose, pavyzdžiui, kai robotų rankos paima komponentus iš vienos vietos ir perkelia į kitą vietą gamybos linijoje. Tai, kad šie varikliai gali judėti ta pačia linkme kiekvieną kartą, padeda gamykloms išlaikyti aukštą gamybos tempą, kartu užtikrinant kokybės standartus. Gamintojams, susiduriantiems su mažomis paklaidomis ir greitomis gamybos ciklais, tokia kartojamumo savybė yra prasminga tiek operacijų, tiek ekonomikos požiūriu.

Vartojimas automatinėje gamybos įrenginyje

Varo konvejerinius sistemos, prievadinimo mašinas ir tekstilės įrangą

NEMA 23 žingsniniai varikliai dabar tapo būtini automatizuotose gamybos sistemose, kurie varo viską – nuo konvejerinių juostų iki mažų montavimo robotų, kuriuos matome surinkimo linijose, taip pat įvairios tekstilės mašinos. Kalbant konkrečiai apie konvejerines sistemas, šie varikliai išsiskiria gebėjimu be pertraukimų sklandžiai perleisti medžiagas per gamyklas, todėl gamyba vyksta nuosekliai. Montavimo operacijoms svarbu tikslumas, nes jie turi užfiksuoti mikrokomponentus ir tiksliai juos nukeliauti ten, kur reikia, neprarandant tikslumo. Tekstilės gamintojai taip pat įvertino NEMA 23 variklius siuvimo ir medžiagos pjaustymo operacijoms. Greitis ir valdymas, kuriuos suteikia šie varikliai, leidžia pasiekti glaudžius gamybos terminus, išlaikant kokybės standartus visose partijose.

Gerina efektyvumą pramoninėje automatizacijoje

NEMA 23 žingsniniai varikliai tapo būtinomis pramonės automatizacijos sistemų dalimis, einančiomis daugiau nei tik judėjimo kontrolė. Šie varikliai leidžia mašinoms veikti patikimai ir tiksliai, todėl gamykloms galima greičiau gaminti prekes ir mažiau švaistyti medžiagų per procesą. Ši technologija taip pat palengvina sudėtingų automatizacijos funkcijų diegimą, sumažinant poreikį darbuotojams kasdien atlikti kartotinus rankinius darbus. Tikrai įdomu, kad šie varikliai leidžia gamintojams kurti modulinę įrangą, kurią galima greitai pakeisti, kai pasikeičia gamybos poreikiai. Gamykla gali perjungti nuo vieno komponento tipo gamybos prie kito vos per kelias valandas tiesiog pakeitus variklio nustatymus. Toks lankstumas padarė NEMA 23 žingsninius variklius daugelio įmonių, siekiančių išlikti konkurencingomis rinkose, kur vartotojų poreikiai nuolat kinta, pirmo pasirinkimo pasirinkimu.

Taikymai medicinos prietaisais

Panaudojama laboratoriniame aprėptiniame įrenginyje, skysčių pompuose ir vaizdavimo sistemose

Medicinos įrenginiai labai pasiklia NEMA 23 žingsniniais varikliais, nes jie siūlo tiek tikslumą, tiek patikimumą. Visos šalių laboratorijos nuolat naudoja šiuos variklius, kad automatizuotų jautrias procedūras, ypač kai tenka valdyti mažytes mėginių apimtis tyrimų metu. Šie varikliai gali perkelti komponentus pirmyn ir atgal pakartotinai, neprarandant tikslumo, o tai laboratorijoms yra būtina kasdieniškai, kad būtų pasiekiami nuoseklūs rezultatai. Kai pažvelgiame į įvairiose medicinos sąvokose naudojamus skysčių siurblius, šie varikliai taip pat puikiai veikia. Jie valdo skysčio judėjimą per vamzdelius su nepaprastu tikslumu, o tai ypač svarbu vaistų tiekimo sistemose, kur net menkiausios klaidos turi didelės įtakos. Net vaizdų gavimo įrenginiuose NEMA 23 varikliai vaidina svarbų vaidmenį. Dėl jų tikslaus pozicionavimo galima gauti aiškesnius vaizdus, nepriklausomai nuo to, ar tai yra magnetinio rezonanso tyrimų (MRI) ar rentgeno nuotraukos, o tai galiausiai leidžia geriau diagnozuoti pacientus. Daugelis technikų iš tiesų mėgsta dirbti su šiais varikliais, nes jie veikia patikimai ilgam laikui.

Tiksliai valdo kritiniuose taikymuose

Medicinos įrenginiuose, kuriuose kiekvieną kartą turi viskas veikti be priekaištų, NEMA 23 žingsniniai varikliai suteikia būtent tai, ko reikia. Šie varikliai užtikrina medicinos įrangos sklandžią veiklą iš dienos į dieną, suteikiant gydytojams ir slaugytojams tikslumą, nuo kurio priklauso svarbūs procedūros. Tai, kas juos išskiria – jų ilgaamžiškumas bei minimalus priežiūros reikalavimas, kas ypač svarbu, kai ligoninės negali sau leisti prastovų. Nuo MRT įrenginių iki pacientų stebėjimo monitorių, šie varikliai padeda įveikti kasdienes operacijas nesukeldami jokio prakaito. Plėtojantis sveikatos priežiūros technologijoms, patikimi komponentai, tokie kaip NEMA 23 varikliai, tampa dar svarbesni siekiant šių dienų aukšto lygio pacientų priežiūros standartų.

Išvada

NEMA 23 žingsniniai varikliai svarbiai prisideda prie daugelio skirtingų pramonės šakų, nes užtikrina puikią tikslumą ir patikimumą, kai tikslumas yra svarbiausias. Paimkite, pavyzdžiui, CNC apdirbimą, kai mažiausios detalės turi būti kartojamos iš naujo, arba pažvelkite į medicinos prietaisus, kuriems reikia veikti su didžiausiu atsargumu. Šie varikliai suteikia tokio tipo kontrolę, kuri reikalinga atlikiant tokį delikatų darbą. Pradžioje sukurti patikimi, jie toliau veikia patikimai net po metų metus, todėl daugelis gamintojų kasdien pasikliauja jais.

NEMA 23 žingsniniai varikliai įmonėms iš visų sektorių suteikia kažką išskirtinio. Jų gebėjimas puikiai veikti daugelyje situacijų leidžia mašinoms dirbti ne tik pagrindines funkcijas. Šiuos variklius šiuolaikinėje visuomenėje galima rasti visur – jie varo gamyklų montavimo linijas ir netgi tikslumą užtikrinančius medicinos įrenginius. Tikra nauda pasirenka, kai įmonės suvokia, kaip geriau jų įranga veikia sumontavus šiuos variklius. Pavyzdžiui, kai kurie medicinos priemonių gamintojai nurodo, kad diagnozavimo įrenginiai tapo tikslesni ir reagavo greičiau, kai pradėjo naudoti NEMA 23 technologijas. Kol sektoriai ieško būdų kaip padidinti efektyvumą nesunaikinant biudžeto, šie universalius variklių modeliai nuolat suranda naujas paskirtis, kurios keičia tai, kas įmanoma modernioje gamyboje.

DUK

Kuo naudojami NEMA 23 žingsnio varikliai?

NEMA 23 žingsnio varikliai naudojami įvairiose programose, įskaitant CNC mašinas, 3D spausdintuvas, robotiką, automatizuotus gamybos įrangas, medicinos prietaisus ir stebėsenos sistemos, dėl jų tikslumo ir patikimumo.

Koks yra NEMA 23 žingsnio variklių sukimo momentų diapazonas?

NEMA 23 žingsnio variklių sukimo momentų specifikacijos kinta nuo 1,0 iki 3,0 Nm, užtikrinant patikimą veikimą skirtingose programose.

Kas daro NEMA 23 žingsnio variklius tinkamas CNC mašinoms?

NEMA 23 žingsnio varikliai siūlo tikslumą ir patikimą sukimo momento išmetimą, todėl jie yra puikiai tinka CNC mašinoms, nes padeda palaikyti tikslumą ir sumažinti nuokrypius operacijų metu.