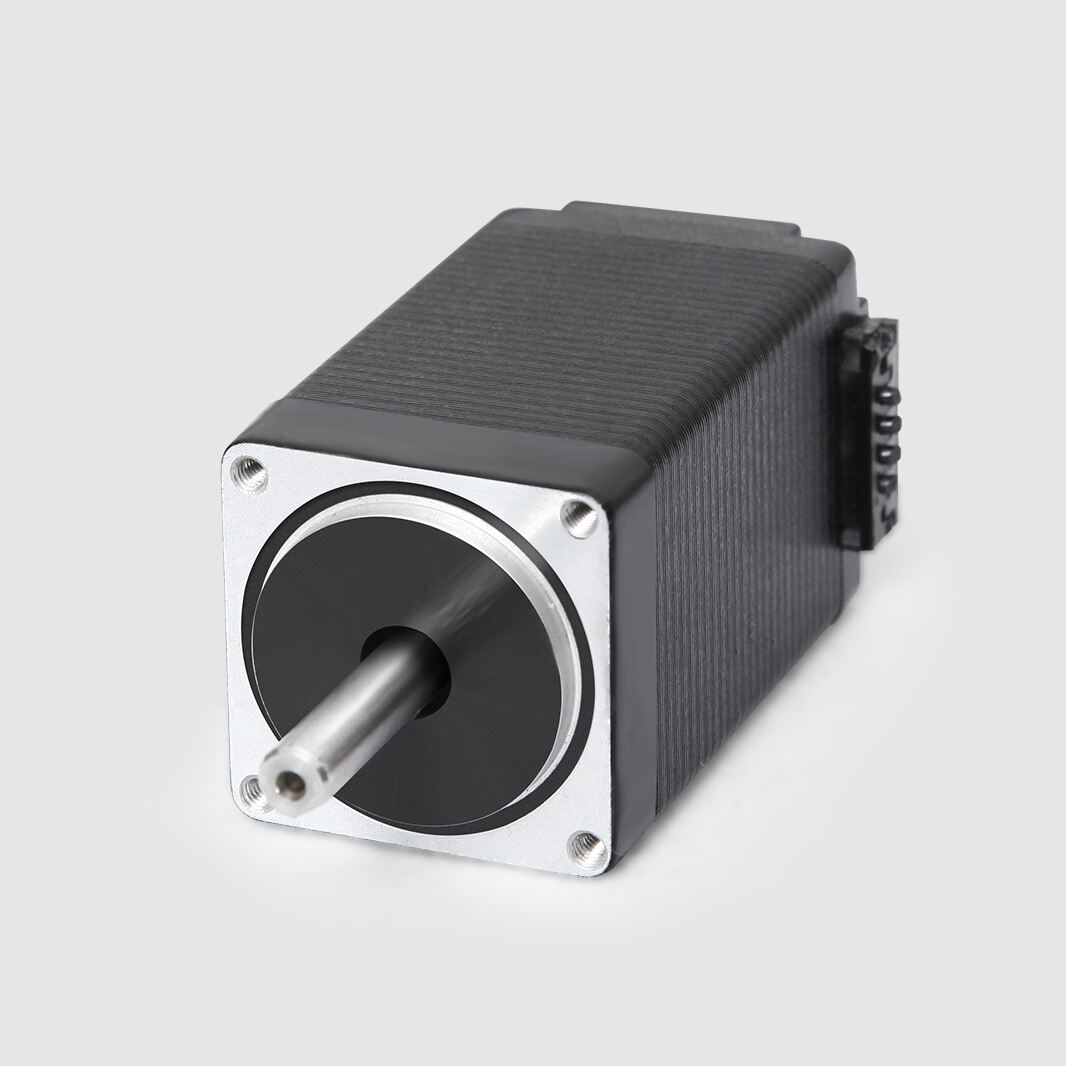

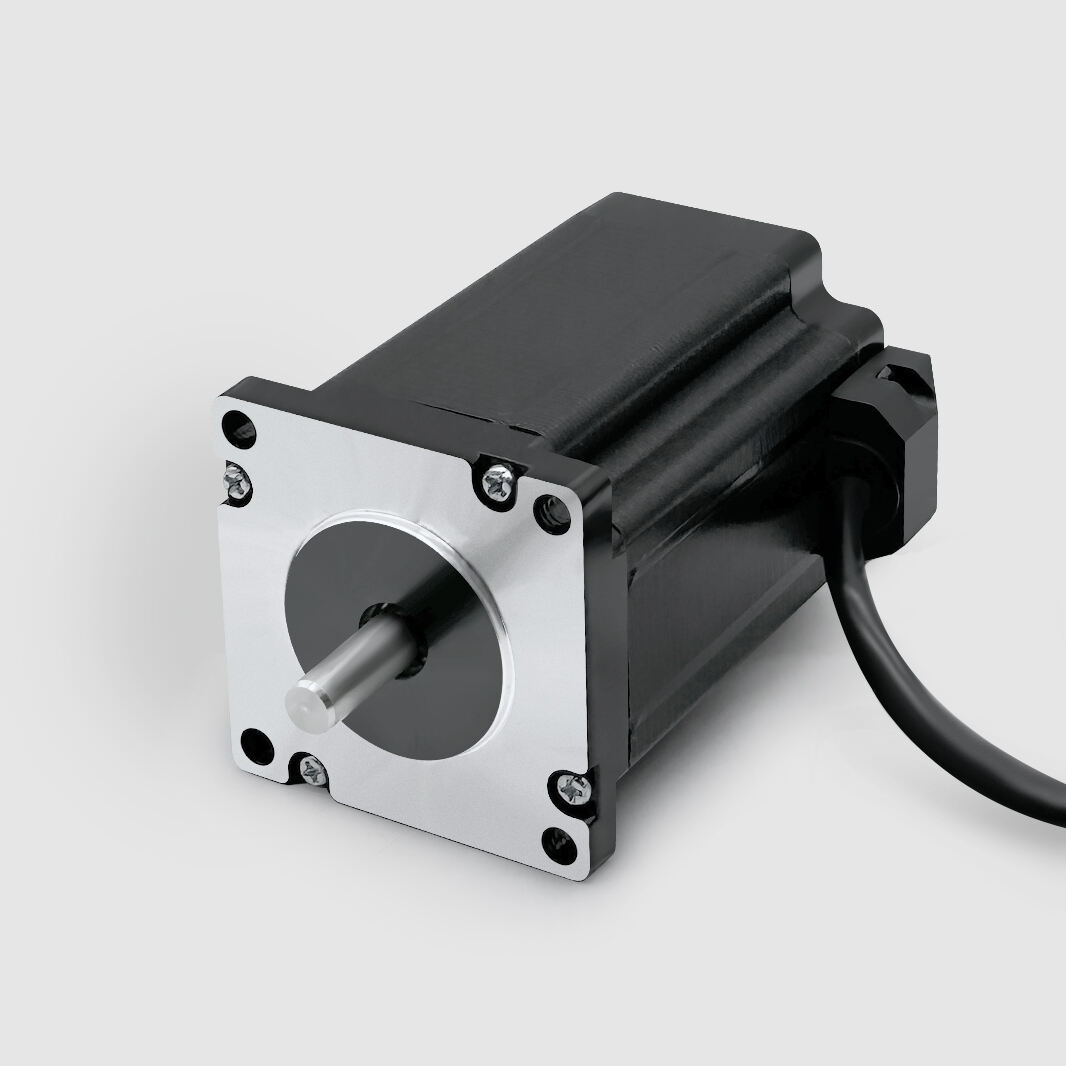

24v stepper driver

The 24v stepper driver is a sophisticated electronic device designed to control the motion of stepper motors by regulating the electrical current. Its main function is to convert a digital input signal into precise mechanical movements. Technological features include compatibility with a wide range of stepper motors, current control that prevents overheating and ensures optimal performance, and advanced microstepping technology that allows for smooth and precise movements. This driver is also equipped with an anti-collision function that protects both the motor and the mechanism. Applications span across various industries, from industrial automation and robotics to 3D printing and CNC machines, where precision and reliability are crucial.