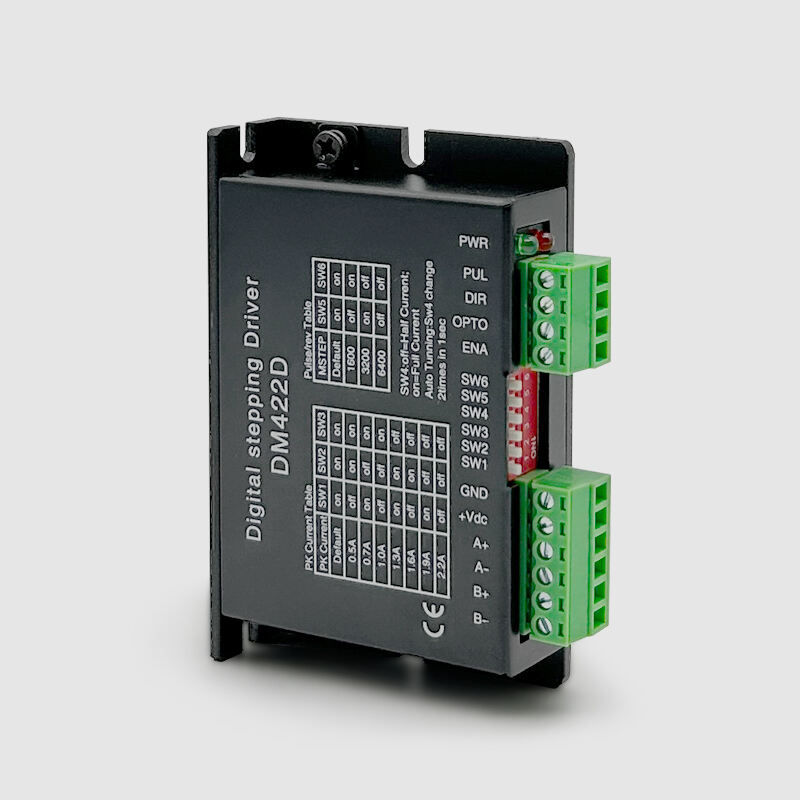

closed loop stepper motor driver

A closed loop stepper motor driver represents a sophisticated advancement in motor control technology, combining the precision of traditional stepper motors with intelligent feedback systems for enhanced performance and reliability. Unlike conventional open-loop stepper motor drivers that operate without position verification, the closed loop stepper motor driver incorporates encoder feedback to continuously monitor and correct motor position, ensuring accurate positioning even under varying load conditions. This innovative technology fundamentally transforms how stepper motors operate by creating a self-correcting system that adapts to real-world conditions. The main functions of a closed loop stepper motor driver include position monitoring through encoder feedback, automatic error correction, stall detection and prevention, and dynamic torque adjustment based on load requirements. The driver processes encoder signals in real-time, comparing actual motor position with commanded position to identify and correct any deviations instantly. Technologically, these drivers feature advanced microprocessor control, high-resolution encoder interfaces, adaptive current control algorithms, and comprehensive fault detection systems. The encoder feedback mechanism typically utilizes optical or magnetic encoders that provide precise position data back to the driver, enabling microsecond-level response times for position corrections. Applications for closed loop stepper motor driver systems span across numerous industries, including CNC machining centers where precise positioning is critical, 3D printing applications requiring consistent layer accuracy, medical equipment demanding reliable movement control, packaging machinery needing synchronized operations, and laboratory automation systems where repeatability is essential. Manufacturing environments particularly benefit from these drivers in assembly line automation, pick-and-place operations, and quality control systems. The closed loop stepper motor driver excels in applications where traditional stepper motors might lose steps due to mechanical interference, sudden load changes, or electrical disturbances, making it an ideal solution for mission-critical positioning tasks that cannot tolerate positioning errors.