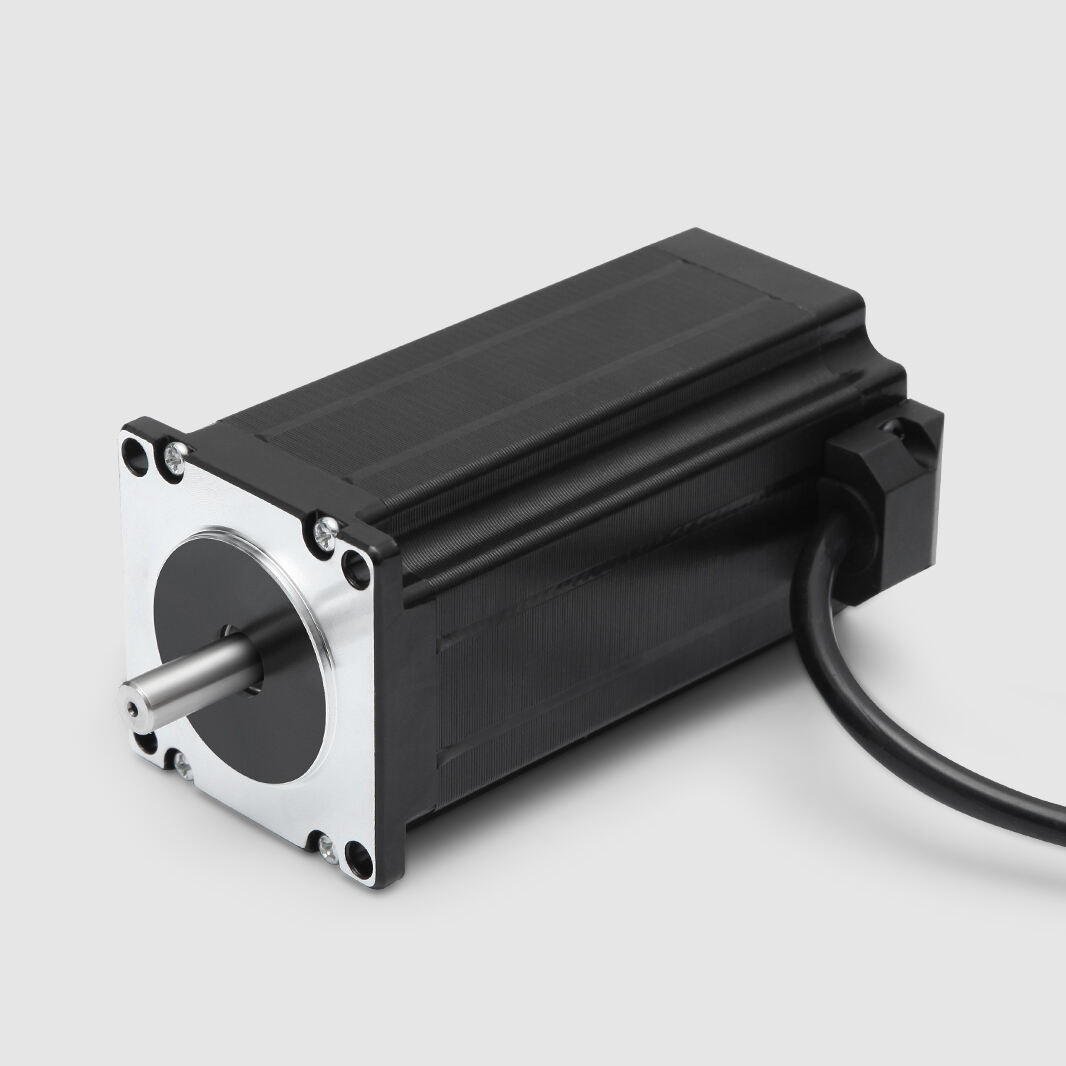

motor motor driver

A motor motor driver represents a sophisticated electronic control system that serves as the essential interface between control circuits and electric motors. This critical component regulates power delivery, manages motor speed, controls direction, and ensures optimal performance across various industrial and commercial applications. The motor motor driver functions as an intelligent bridge that translates low-power control signals into high-power outputs capable of driving different motor types including DC motors, stepper motors, and servo motors. Modern motor motor driver systems incorporate advanced semiconductor technology, utilizing power transistors, MOSFETs, and integrated circuits to achieve precise control over motor operations. These systems feature built-in protection mechanisms such as overcurrent protection, thermal shutdown, and voltage regulation to safeguard both the driver and connected motors from potential damage. The motor motor driver typically includes pulse width modulation capabilities, enabling smooth speed control and energy-efficient operation. Advanced models offer programmable parameters, allowing users to customize acceleration curves, deceleration rates, and torque characteristics according to specific application requirements. Communication interfaces such as SPI, I2C, or UART enable seamless integration with microcontrollers and automation systems. The motor motor driver architecture often incorporates feedback systems that monitor motor performance in real-time, providing closed-loop control for enhanced accuracy and reliability. Temperature monitoring, current sensing, and position feedback capabilities ensure consistent operation under varying load conditions. Many motor motor driver units support multiple motor configurations, from single-axis control to complex multi-motor coordination systems used in robotics and manufacturing automation.