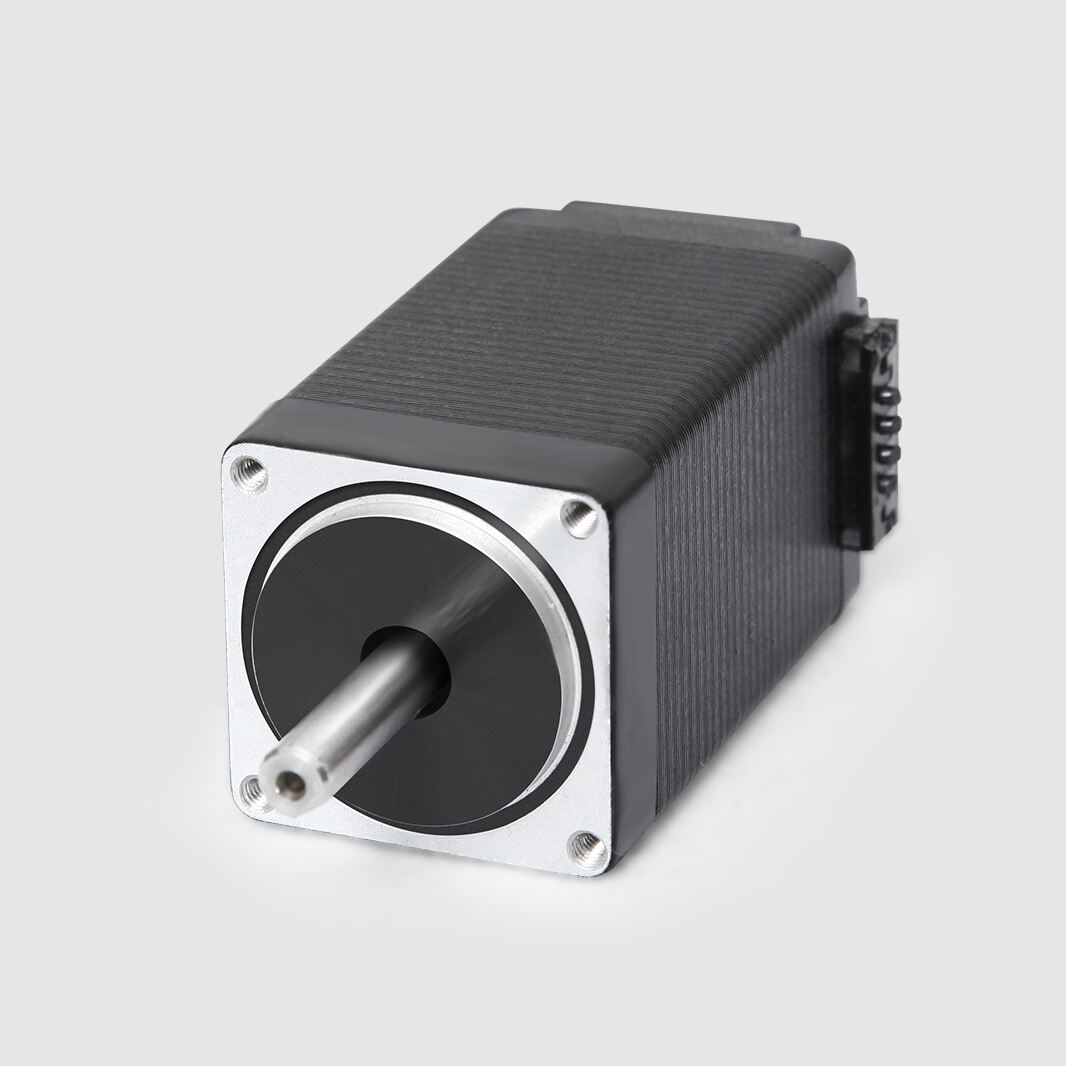

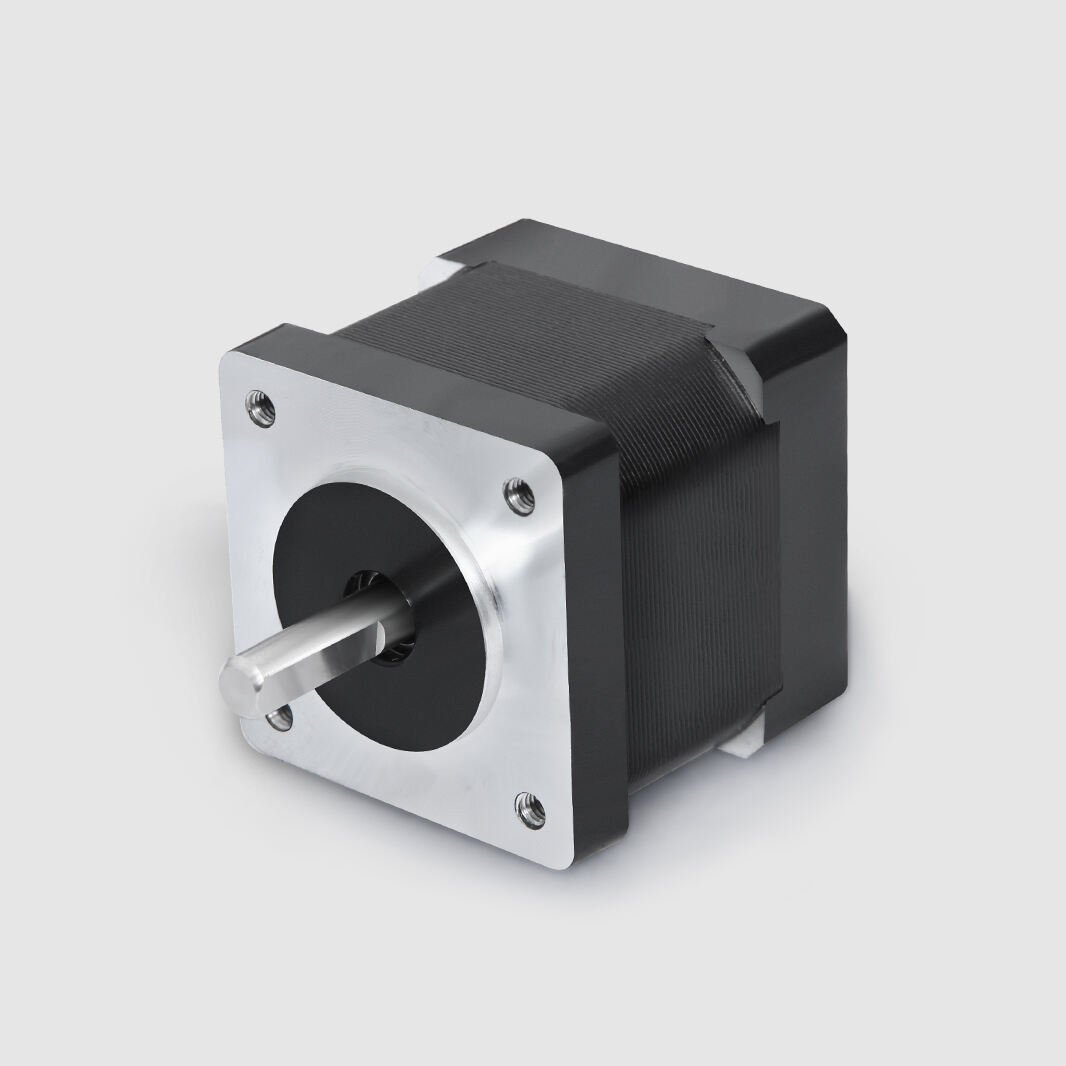

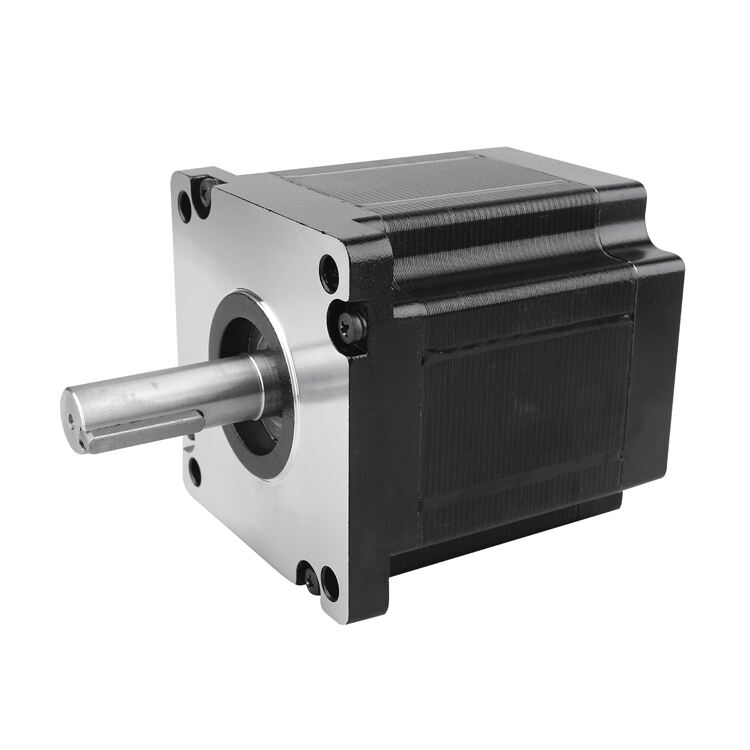

nema 17 geared stepper motor

The nema 17 geared stepper motor represents a sophisticated advancement in precision motion control technology, combining the reliable positioning capabilities of standard stepper motors with the enhanced torque multiplication benefits of integrated gear reduction systems. This compact yet powerful motor solution measures 42mm x 42mm in its mounting face, adhering to the internationally recognized NEMA 17 standard dimensions that ensure universal compatibility across diverse industrial applications. The fundamental operating principle involves precise electrical pulse conversion into discrete mechanical movements, where each input pulse corresponds to a specific angular rotation increment. The integrated planetary or spur gear system dramatically increases the output torque while simultaneously reducing the effective step resolution, enabling exceptionally precise positioning control for demanding applications. Key technological features include high holding torque capabilities ranging from 0.5 to 5.0 Nm depending on gear ratios, step accuracies typically within ±3 arc-minutes, and gear reduction ratios spanning from 3.71:1 to 100:1 configurations. The motor construction incorporates permanent magnet rotors with multi-phase stator windings, usually configured in bipolar arrangements for optimal performance characteristics. Advanced manufacturing techniques ensure minimal backlash in gear systems, typically maintained below 1 degree for superior positioning repeatability. Temperature resistance capabilities allow continuous operation in environments ranging from -20°C to +85°C, making these motors suitable for both indoor precision equipment and outdoor industrial machinery. The nema 17 geared stepper motor finds extensive applications in 3D printing systems, CNC machinery, robotics automation, medical equipment positioning systems, packaging machinery, and laboratory instrumentation where precise, repeatable motion control is essential for operational success and product quality maintenance.