Versatile Integration and Control Simplicity

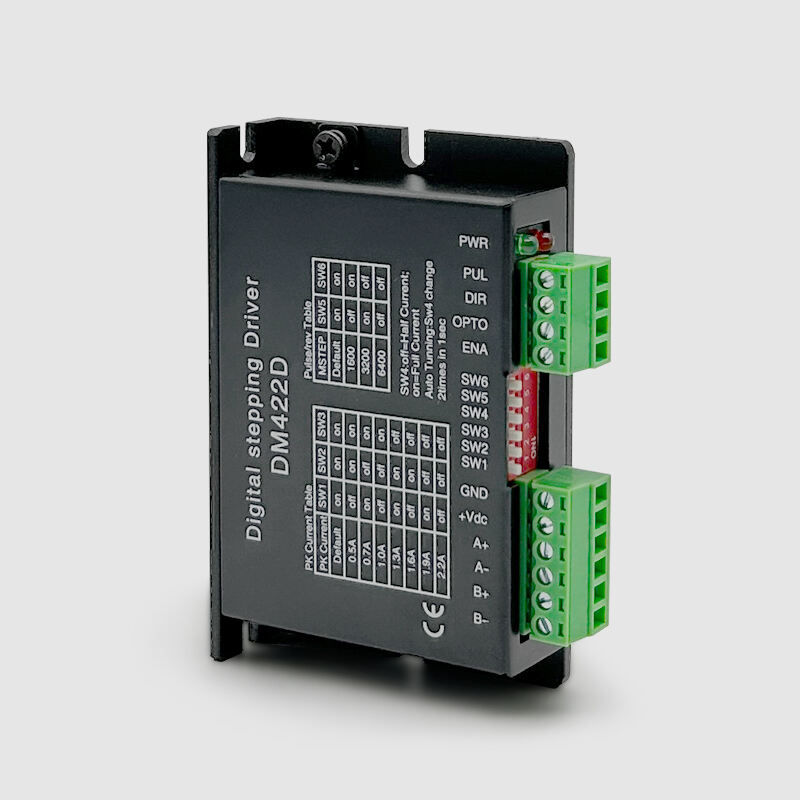

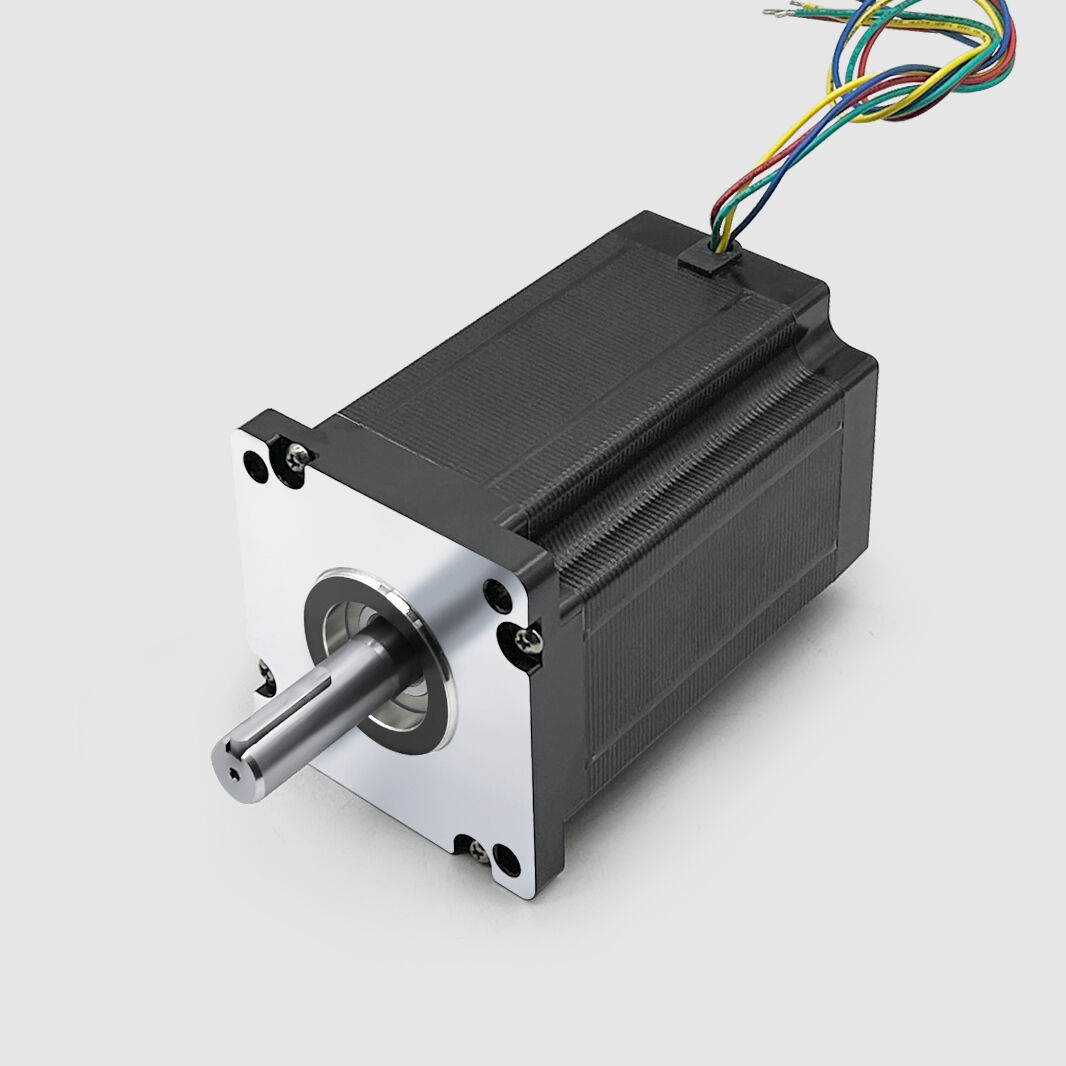

The hybrid stepper motor's exceptional integration versatility and control simplicity make it the preferred choice for engineers seeking reliable motion solutions without complex programming or extensive technical expertise. These motors accept standard digital pulse trains for position and speed control, requiring only step pulse and direction signals to operate effectively, which dramatically simplifies system integration compared to servo motors requiring analog command signals and complex tuning procedures. The straightforward control interface enables direct connection to programmable logic controllers, microcontrollers, and computer systems using common digital outputs, eliminating the need for specialized motion control cards or expensive drive amplifiers. Users can implement precise motion control using simple programming commands or even manual pulse generation, making hybrid stepper motors accessible to engineers with varying technical backgrounds. The motors support multiple control modes including full-step, half-step, and microstepping operation, allowing users to optimize performance for specific applications without hardware changes. Microstepping capability provides smooth motion at low speeds and reduces resonance issues, while full-stepping delivers maximum torque for high-load applications. The inherent digital nature of hybrid stepper control enables easy integration with modern industrial automation systems, IoT devices, and Industry 4.0 applications where precise positioning data and control status information are essential. Standard communication protocols including pulse/direction, serial communication, and fieldbus interfaces facilitate seamless integration with existing control architectures. The motors operate reliably across wide voltage ranges and accept various input signal types, providing flexibility for different electrical environments and control systems. Built-in protection features including overcurrent detection, thermal monitoring, and short-circuit protection ensure safe operation even in harsh industrial conditions. System designers appreciate the scalability of hybrid stepper solutions, as multiple motors can operate synchronously from a single controller, enabling complex multi-axis applications with coordinated motion profiles. The plug-and-play nature of hybrid stepper systems reduces commissioning time and eliminates complex setup procedures, allowing faster project completion and reduced engineering costs. Diagnostic capabilities built into modern hybrid stepper drives provide real-time status information and fault detection, enabling predictive maintenance strategies and minimizing unexpected downtime.