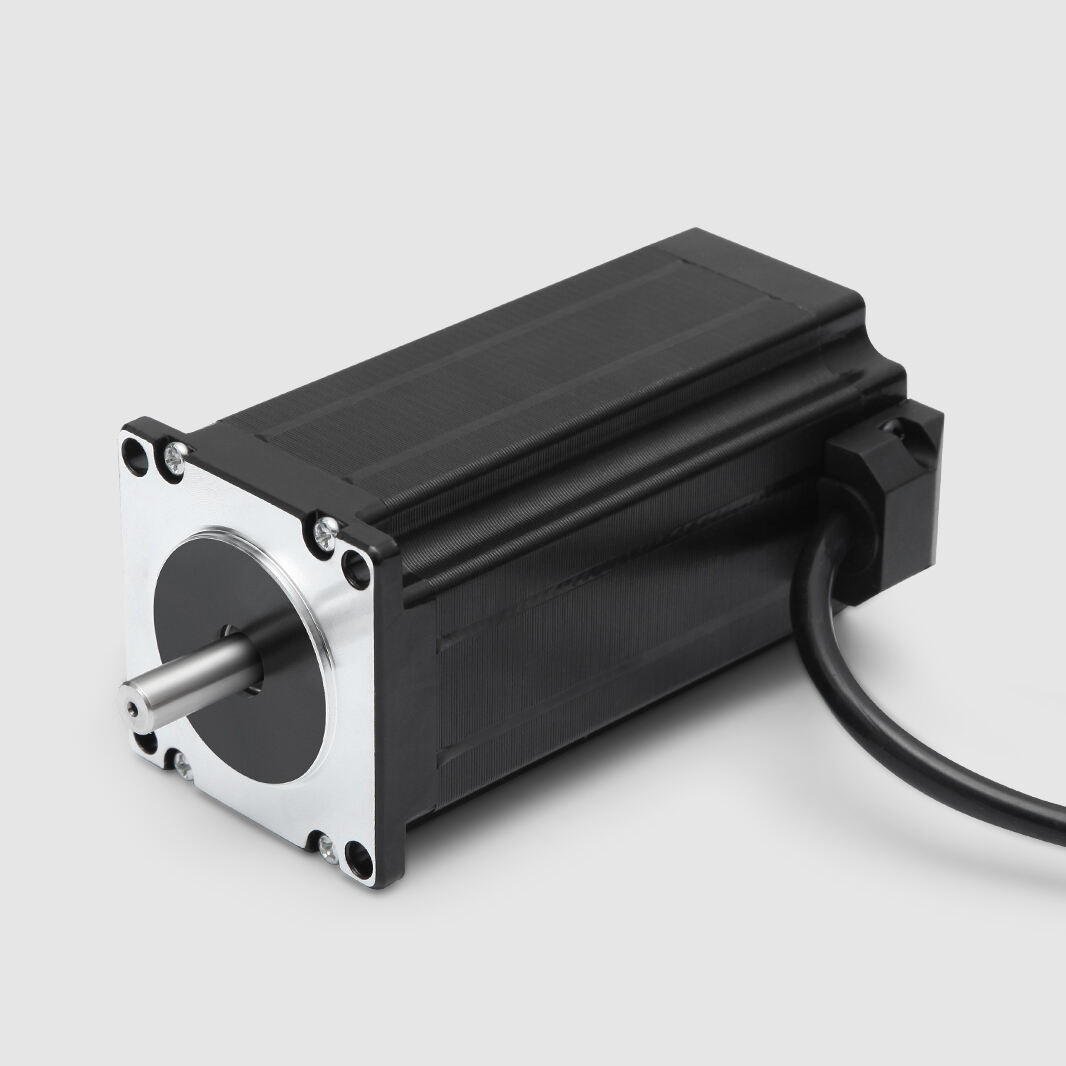

stepper motor brushless

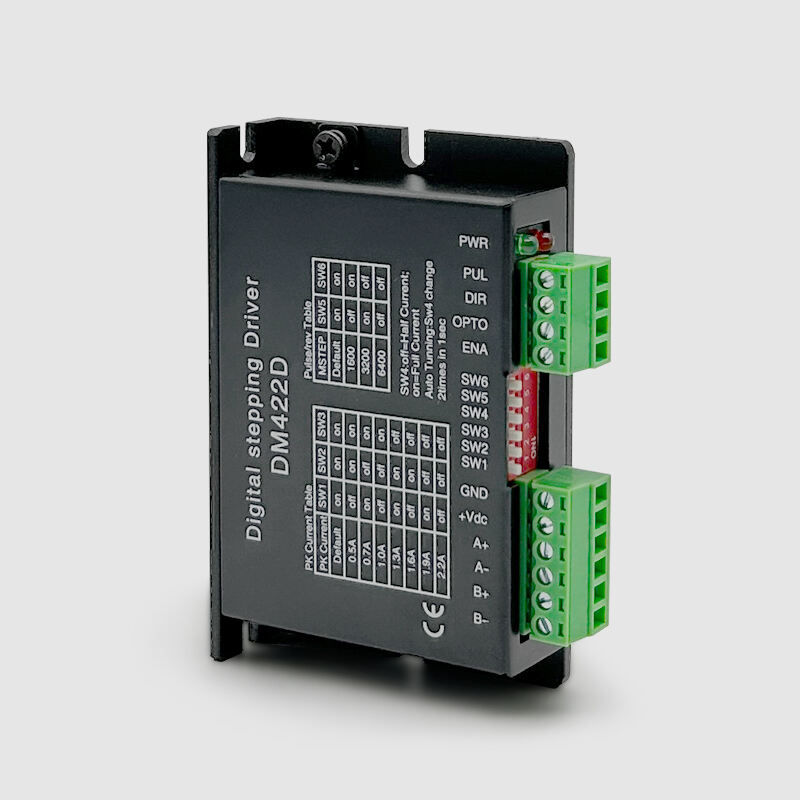

A stepper motor brushless represents a revolutionary advancement in precision motion control technology, combining the accurate positioning capabilities of traditional stepper motors with the enhanced efficiency and longevity of brushless design. This sophisticated motor system operates by converting digital pulse signals into precise mechanical rotation, enabling exceptional control over speed, position, and torque without requiring feedback systems. The stepper motor brushless utilizes electronic commutation instead of physical brushes, eliminating mechanical wear points and significantly extending operational lifespan. The core functionality revolves around electromagnetic field switching, where the motor's rotor follows a rotating magnetic field created by electronically controlled stator windings. This process ensures smooth, quiet operation while maintaining precise step-by-step movement. Technological features include advanced driver circuits that manage current flow to individual motor phases, optimizing performance while minimizing heat generation. The stepper motor brushless incorporates sophisticated control algorithms that enable microstepping capabilities, allowing for incredibly fine positioning resolution far beyond traditional stepping increments. These motors excel in applications requiring precise positioning without complex feedback systems, making them ideal for 3D printers, CNC machines, robotics, medical equipment, and automated manufacturing systems. The versatility of stepper motor brushless technology extends to various industrial sectors including packaging machinery, textile equipment, and laboratory automation. Their ability to maintain holding torque when stationary makes them particularly valuable for applications requiring stable positioning under load. The integration of modern materials and manufacturing techniques has enabled stepper motor brushless units to achieve higher power densities while maintaining compact form factors. This technology supports both open-loop and closed-loop control systems, providing flexibility for different application requirements while ensuring reliable, repeatable performance across diverse operating conditions and environments.