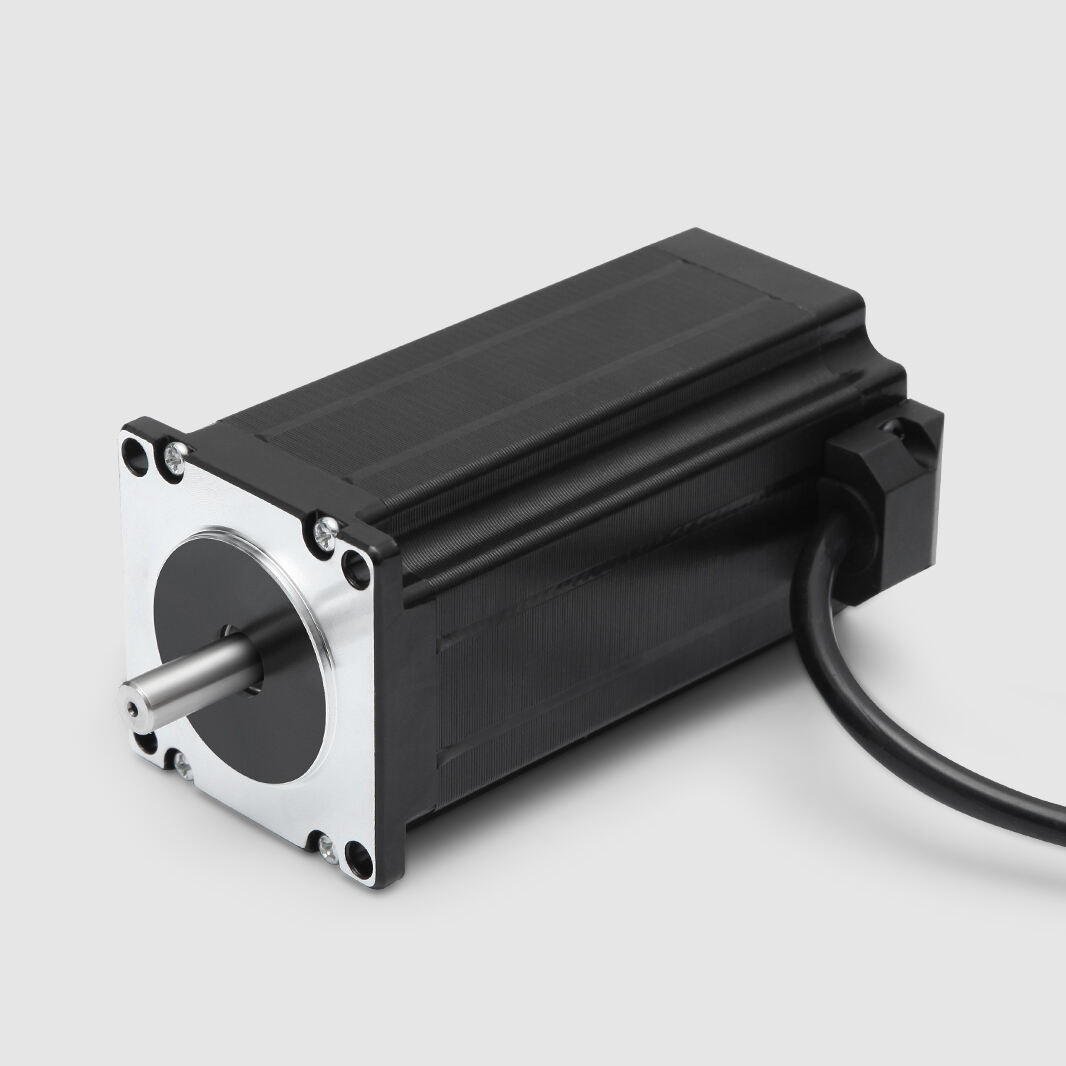

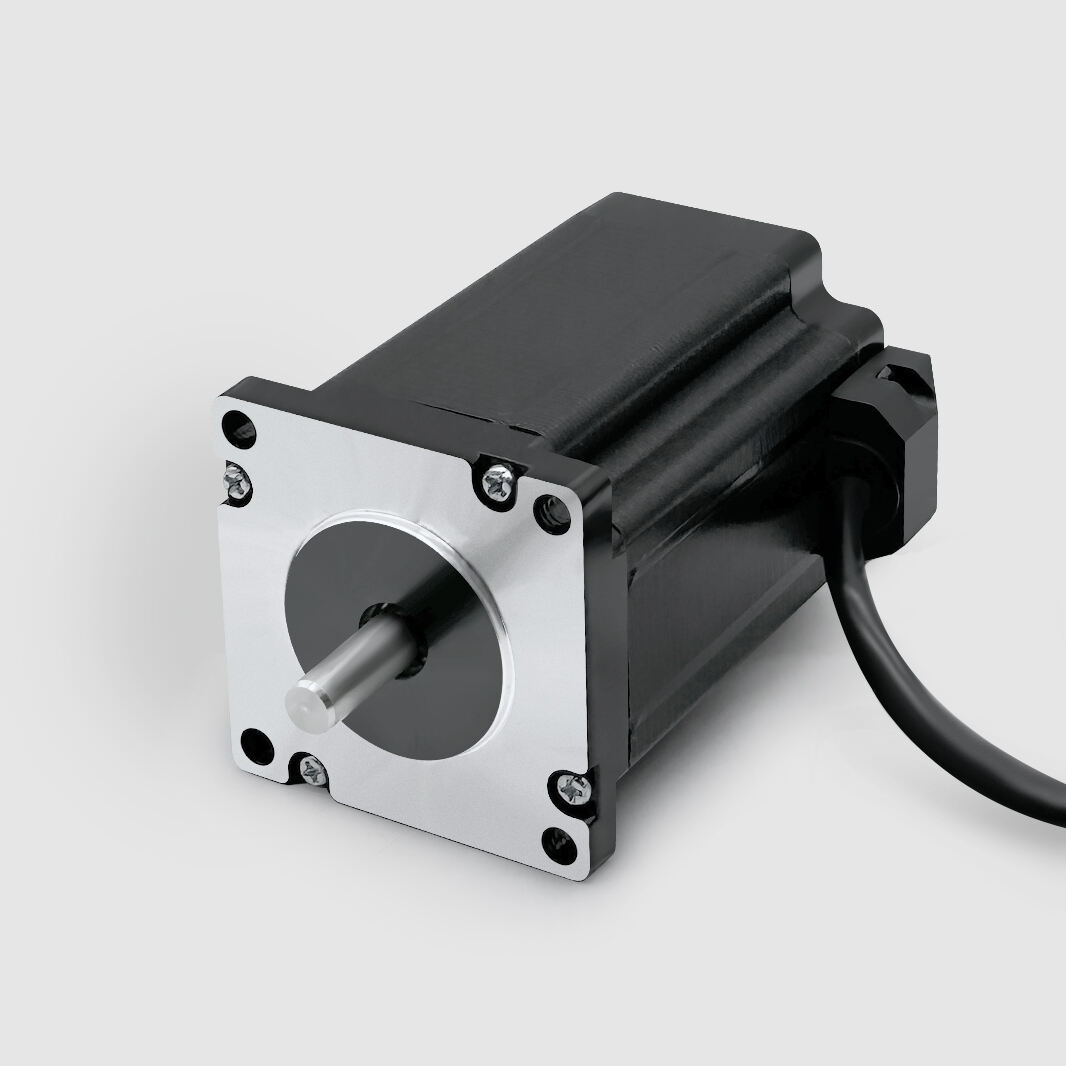

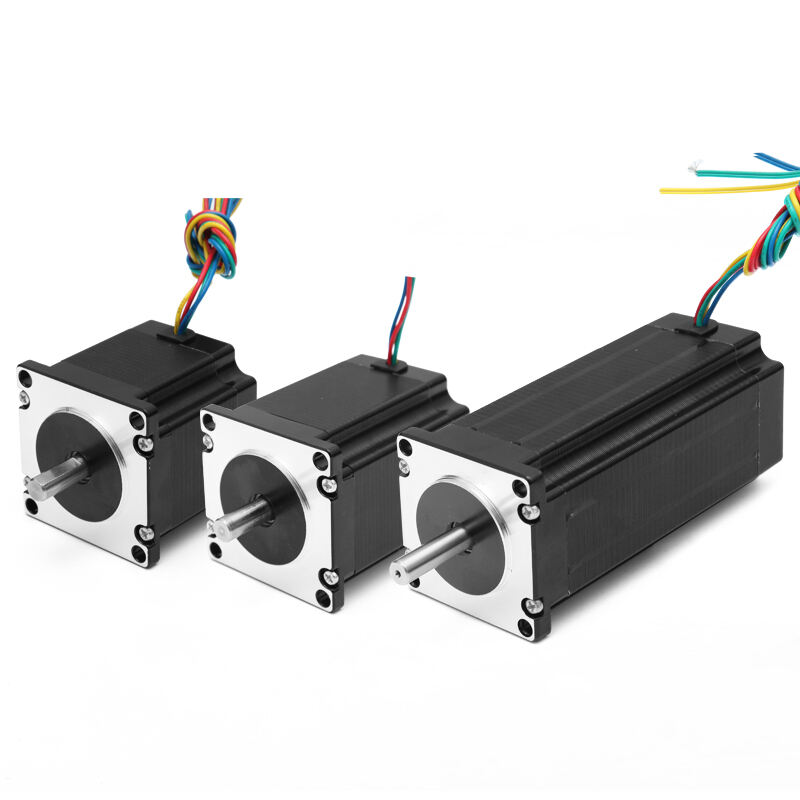

integrated stepper motor

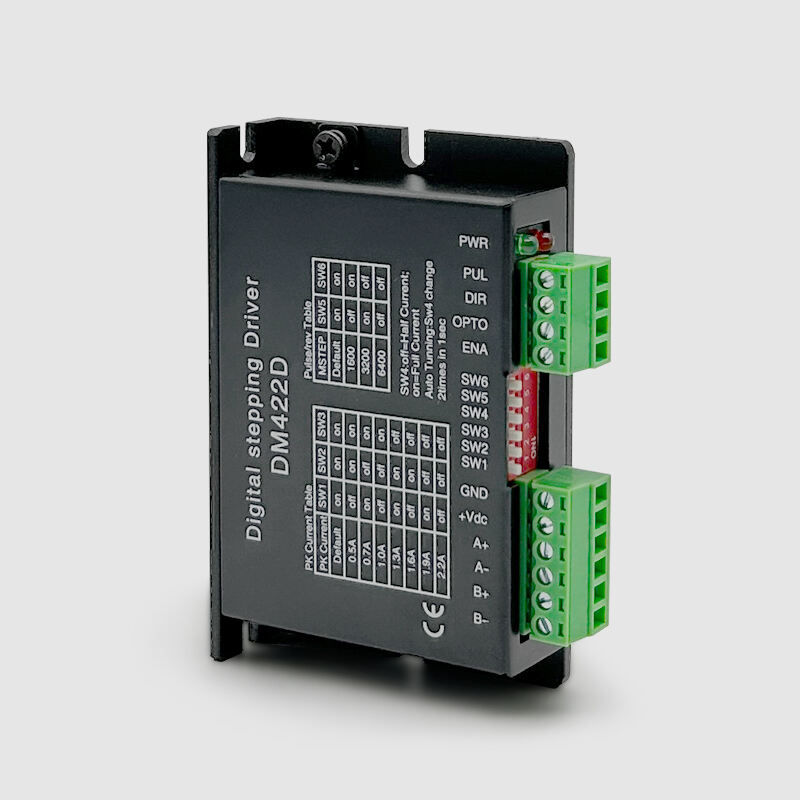

An integrated stepper motor represents a revolutionary advancement in precision motion control technology, combining the traditional stepper motor with built-in driver electronics and control systems within a single compact unit. This integrated stepper motor eliminates the need for external drivers, significantly simplifying system design and reducing installation complexity. The primary function of an integrated stepper motor involves converting digital pulse signals directly into precise angular movements, enabling accurate positioning without requiring feedback systems. The technological foundation relies on electromagnetic principles where digital pulses control the sequential energization of motor windings, creating step-by-step rotation with exceptional repeatability. Modern integrated stepper motor designs incorporate advanced microprocessor-based control algorithms that optimize torque delivery, minimize vibration, and enhance overall performance characteristics. These motors feature built-in current regulation, thermal protection, and communication interfaces that facilitate seamless integration with various control systems. The integrated stepper motor typically includes RS-485, CANopen, or Ethernet connectivity options, enabling network-based control and monitoring capabilities. Applications span numerous industries including medical equipment, laboratory automation, packaging machinery, textile manufacturing, 3D printing, robotics, and precision manufacturing systems. In medical applications, the integrated stepper motor provides the exact positioning required for diagnostic equipment, surgical robots, and drug dispensing systems. Manufacturing environments utilize these motors for conveyor systems, assembly line positioning, and quality control equipment where precise movement control is essential. The integrated stepper motor design incorporates advanced heat dissipation mechanisms and robust construction materials to ensure reliable operation in demanding industrial environments. Energy efficiency optimization features reduce power consumption while maintaining high torque output, making the integrated stepper motor an environmentally conscious choice for sustainable manufacturing operations.