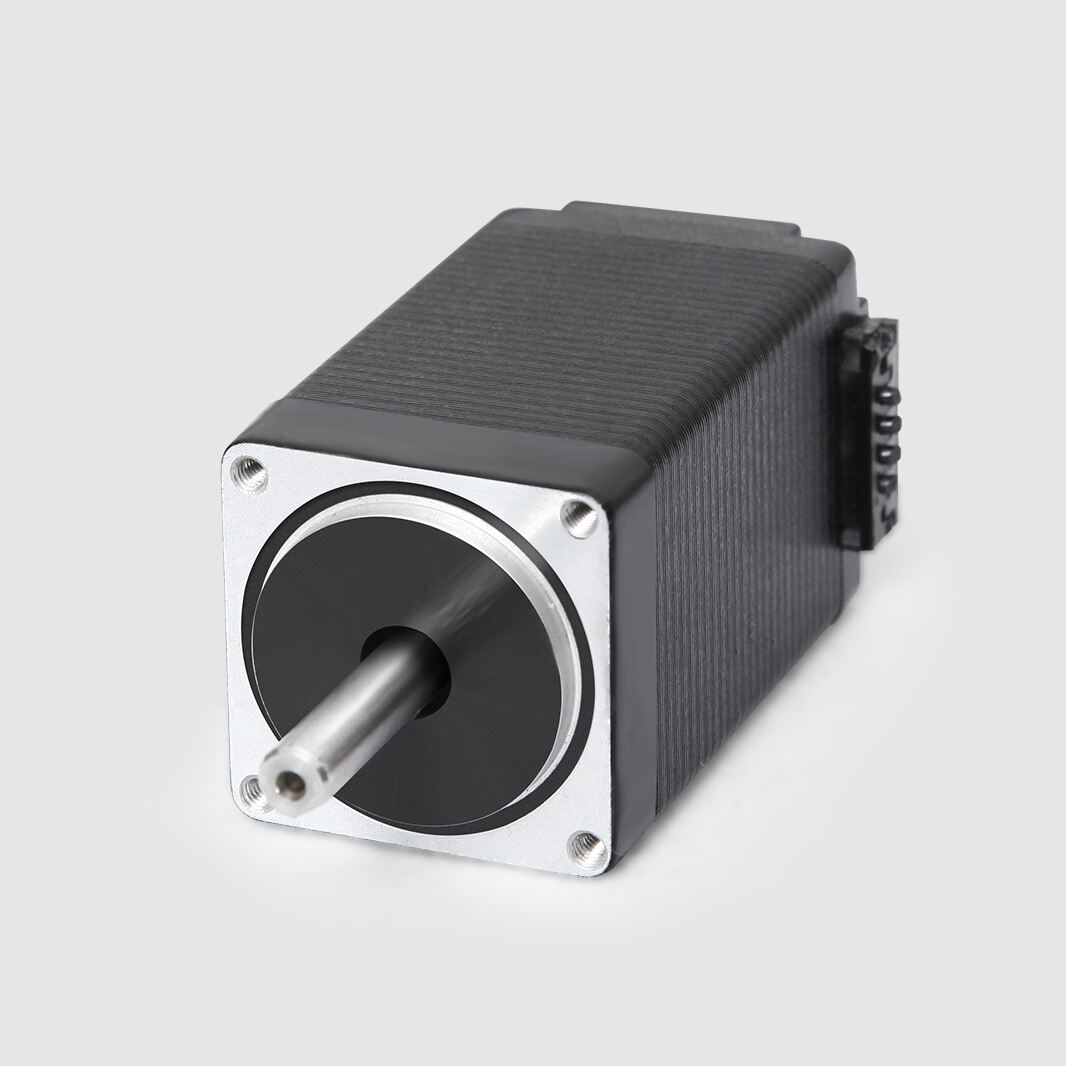

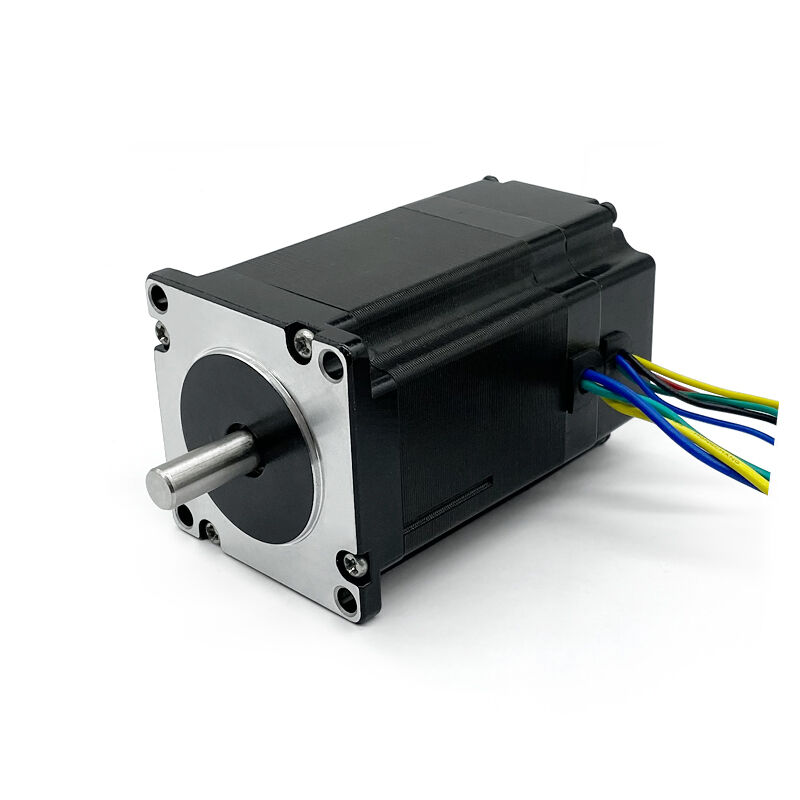

big stepper motor

The big stepper motor represents a significant advancement in precision motion control technology, designed to handle demanding applications that require substantial torque output and exceptional positioning accuracy. Unlike conventional motors, this robust system operates by dividing full rotations into discrete steps, enabling precise angular positioning without the need for feedback sensors. The big stepper motor incorporates advanced electromagnetic design principles, featuring multiple pole configurations and high-grade magnetic materials that deliver superior performance across various industrial sectors. These motors typically feature larger frame sizes, enhanced cooling systems, and reinforced construction to withstand continuous operation under challenging conditions. The technological foundation of the big stepper motor relies on sophisticated driver circuits that control current flow through multiple windings, creating rotating magnetic fields that produce smooth, controlled motion. Modern big stepper motor designs incorporate microstepping capabilities, allowing for even finer resolution control and reduced vibration during operation. The motor's construction includes precision-machined rotors, high-temperature resistant windings, and durable bearing systems that ensure long-term reliability. Key technological features include programmable acceleration and deceleration profiles, multiple operating modes, and compatibility with various control interfaces including pulse-direction, serial communication, and industrial fieldbus protocols. Applications for the big stepper motor span across manufacturing automation, robotics, CNC machinery, medical equipment, packaging systems, and scientific instrumentation. In manufacturing environments, these motors drive conveyor systems, assembly line components, and material handling equipment with exceptional repeatability. The aerospace industry utilizes big stepper motors for antenna positioning, valve control, and testing equipment where precise movement is critical. Laboratory automation systems rely on these motors for sample handling, microscope positioning, and analytical instrument control, benefiting from their ability to maintain position without continuous power consumption.