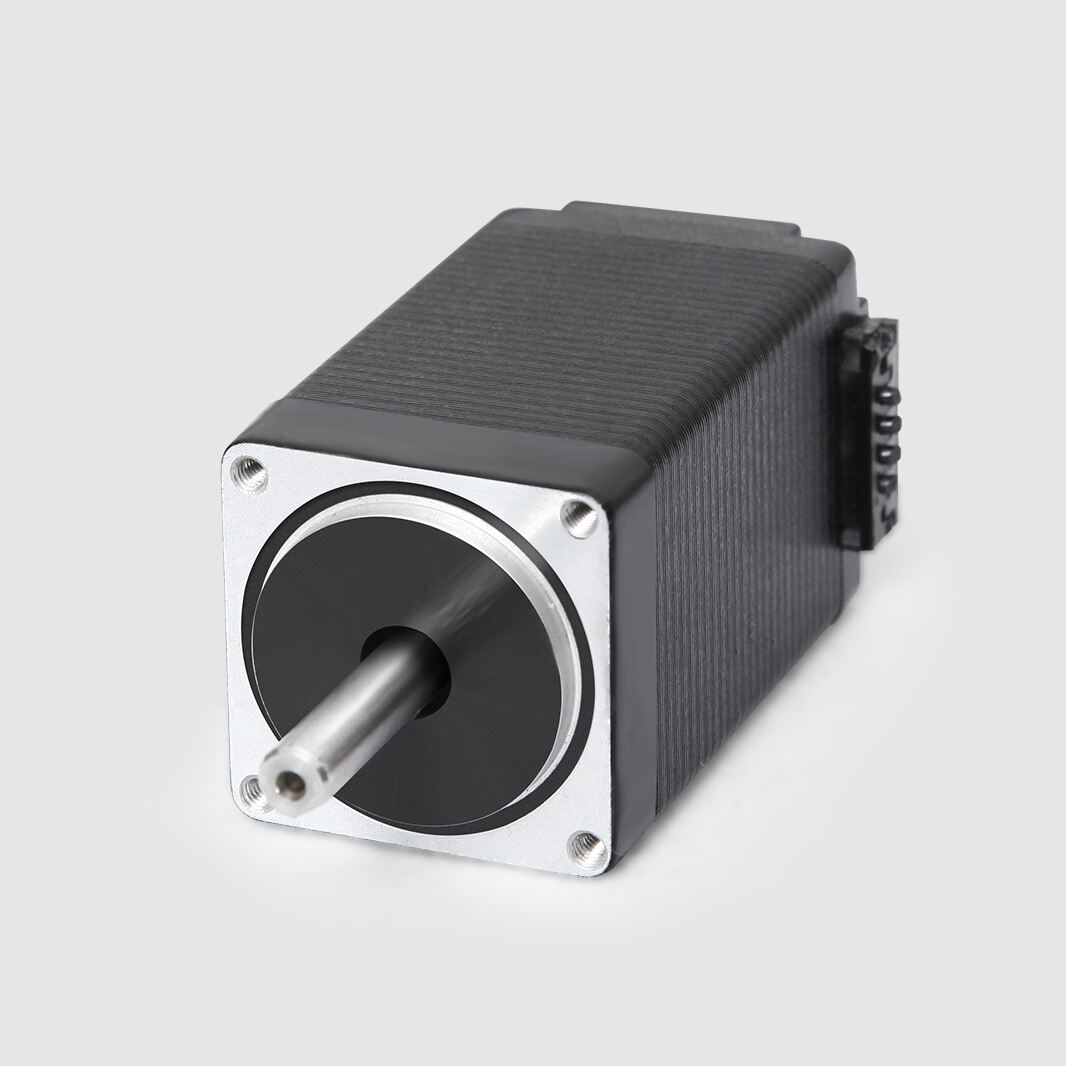

stepper motor controller kit

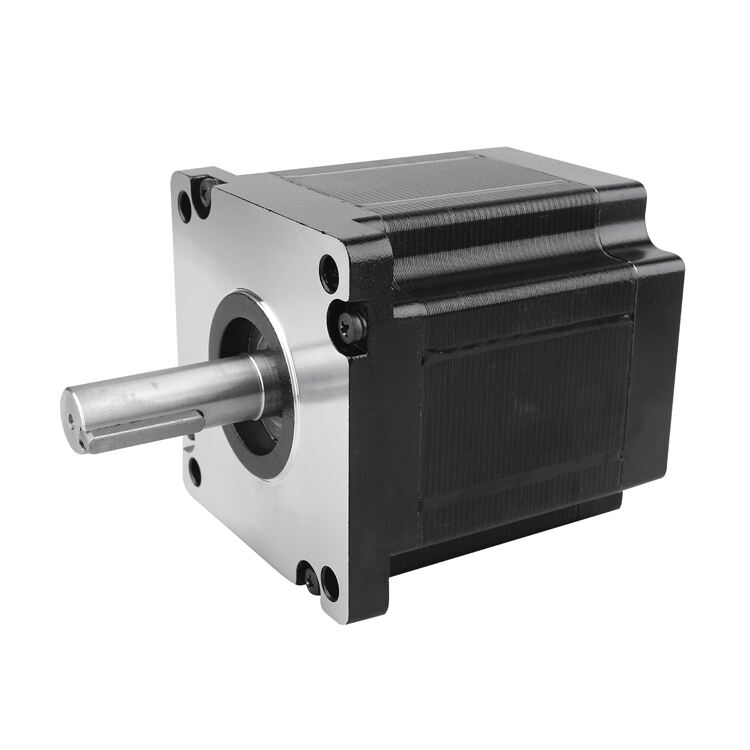

A stepper motor controller kit represents a comprehensive solution for precise motor control applications, combining advanced electronic components with user-friendly interfaces to deliver exceptional performance across various industrial and hobbyist projects. These sophisticated control systems enable users to achieve accurate positioning, smooth motion profiles, and reliable operation in demanding environments. The stepper motor controller kit typically includes a microprocessor-based control unit, power driver circuits, pulse generation modules, and comprehensive software packages that work together seamlessly. Modern stepper motor controller kits incorporate cutting-edge digital signal processing technology, allowing for micro-stepping capabilities that enhance resolution and reduce vibration during operation. The integrated feedback systems provide real-time monitoring of motor performance, ensuring optimal efficiency and preventing potential issues before they occur. These kits support multiple communication protocols including USB, RS232, and Ethernet connectivity, enabling seamless integration with existing automation systems and computer networks. The versatile design accommodates various stepper motor types, from small NEMA 8 motors to large NEMA 34 units, making the stepper motor controller kit suitable for diverse applications ranging from 3D printing and CNC machining to robotics and automated manufacturing equipment. Advanced features include programmable acceleration and deceleration curves, position holding capabilities, and emergency stop functions that ensure safe operation in critical applications. The stepper motor controller kit also offers extensive customization options through software configuration tools, allowing users to optimize performance parameters for specific operational requirements. Temperature monitoring and protection circuits safeguard both the controller and connected motors from thermal damage, while overcurrent protection prevents electrical failures. The compact design and modular architecture of modern stepper motor controller kits facilitate easy installation and maintenance, reducing downtime and operational costs for end users.