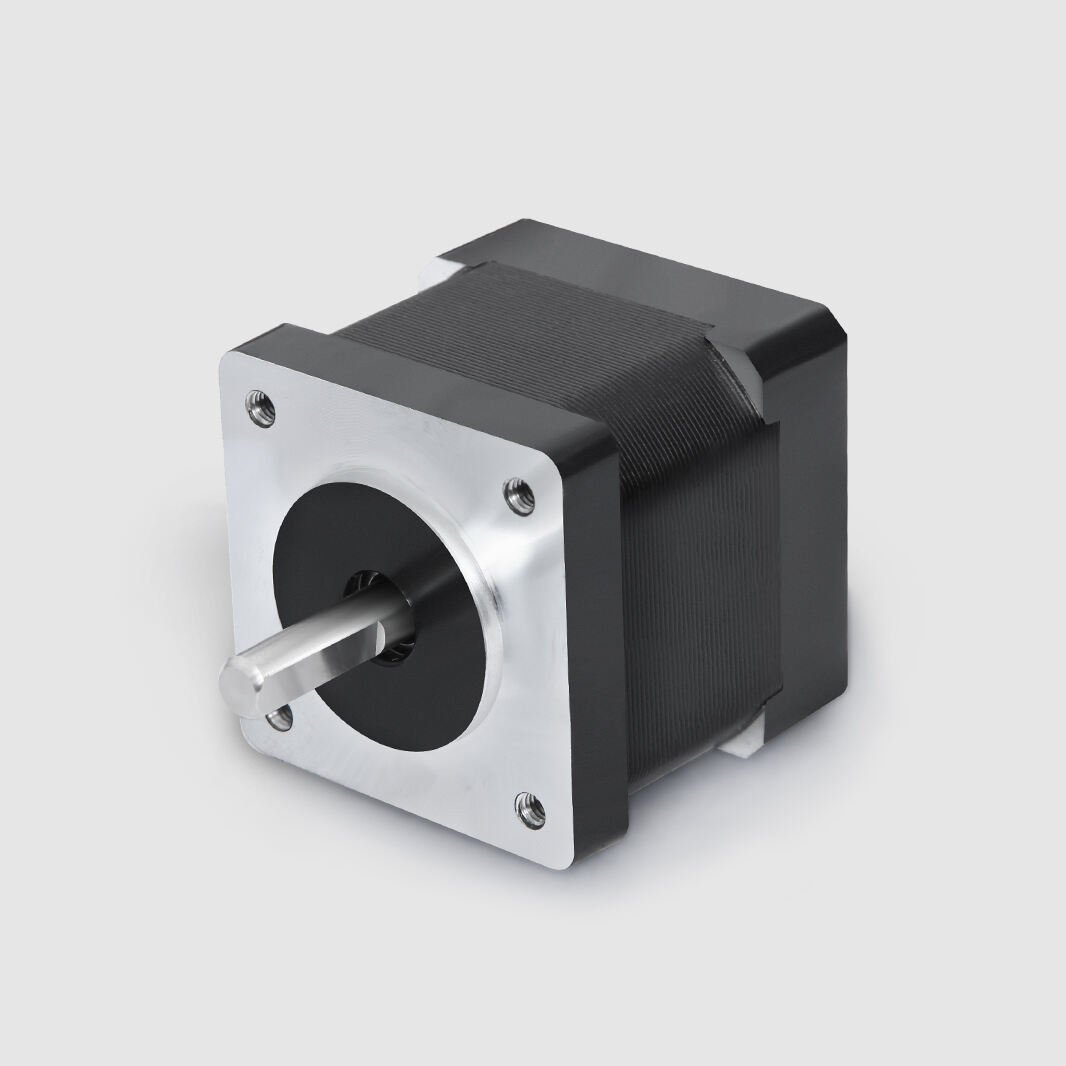

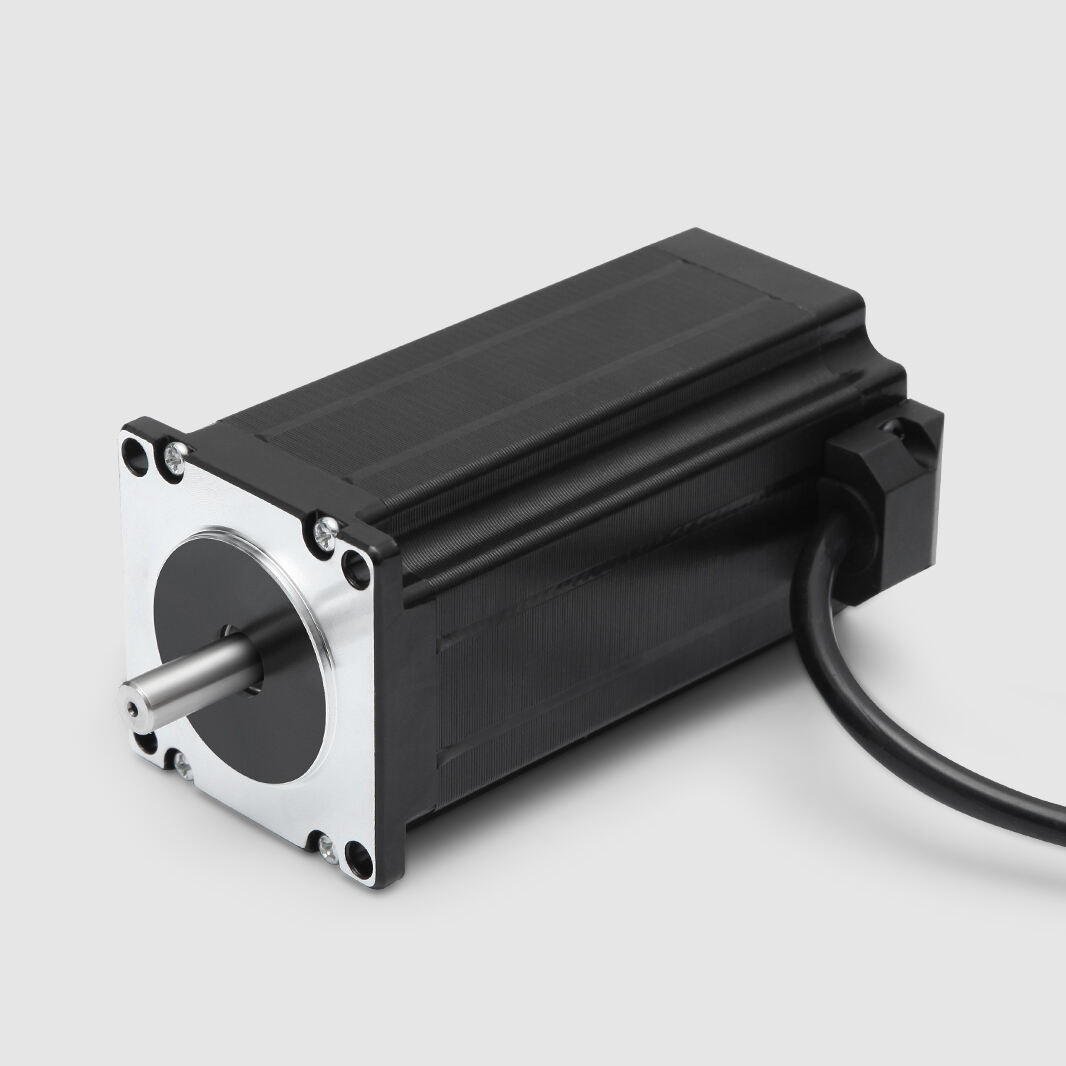

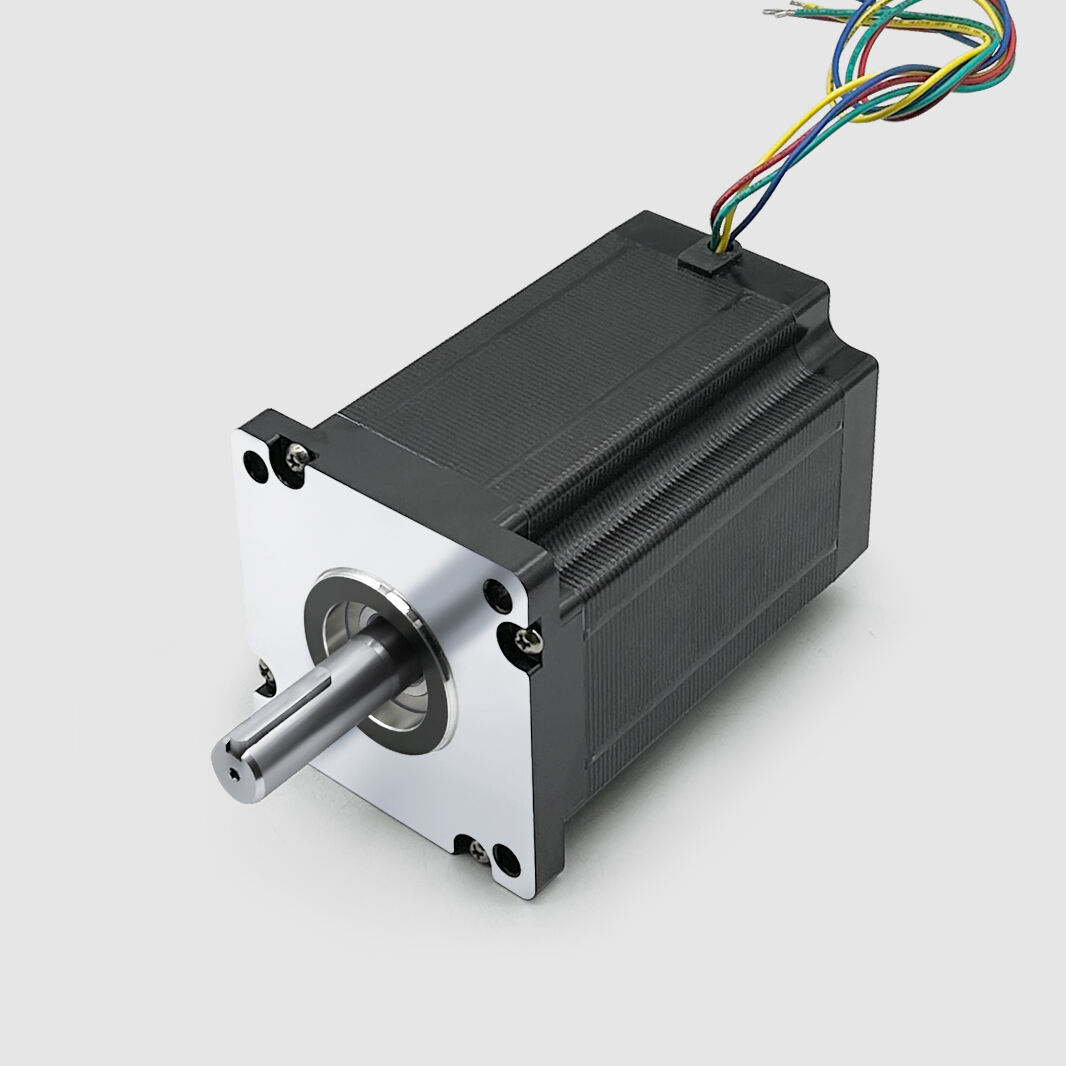

closed loop stepper motor nema 23

The closed loop stepper motor nema 23 represents a significant advancement in precision motor technology, combining the traditional benefits of stepper motors with modern feedback control systems. This sophisticated motor design incorporates an encoder or other feedback device that continuously monitors the rotor position, creating a closed loop control system that dramatically improves accuracy and performance. The nema 23 designation refers to the standardized mounting dimensions, with a 2.3-inch square faceplate that ensures compatibility across various applications and mounting systems. The closed loop stepper motor nema 23 delivers exceptional torque characteristics while maintaining precise positioning control, making it ideal for demanding industrial applications. The main functions of this motor include precise angular positioning, variable speed control, and high holding torque capabilities. The technological features encompass advanced encoder feedback systems, typically optical or magnetic encoders that provide real-time position data to the control system. This feedback mechanism enables the motor to detect and correct any position errors, preventing the step loss issues commonly associated with traditional open-loop stepper motors. The closed loop stepper motor nema 23 also features enhanced thermal management systems, improved efficiency ratings, and reduced vibration characteristics compared to conventional stepper motors. Applications for this motor span numerous industries including automated manufacturing equipment, CNC machines, 3D printing systems, robotic positioning systems, medical devices, packaging machinery, and precision instrumentation. The motor excels in environments requiring consistent repeatability, smooth operation at various speeds, and reliable performance under varying load conditions. The closed loop stepper motor nema 23 particularly shines in applications where traditional stepper motors might lose steps due to unexpected load variations or resonance issues.