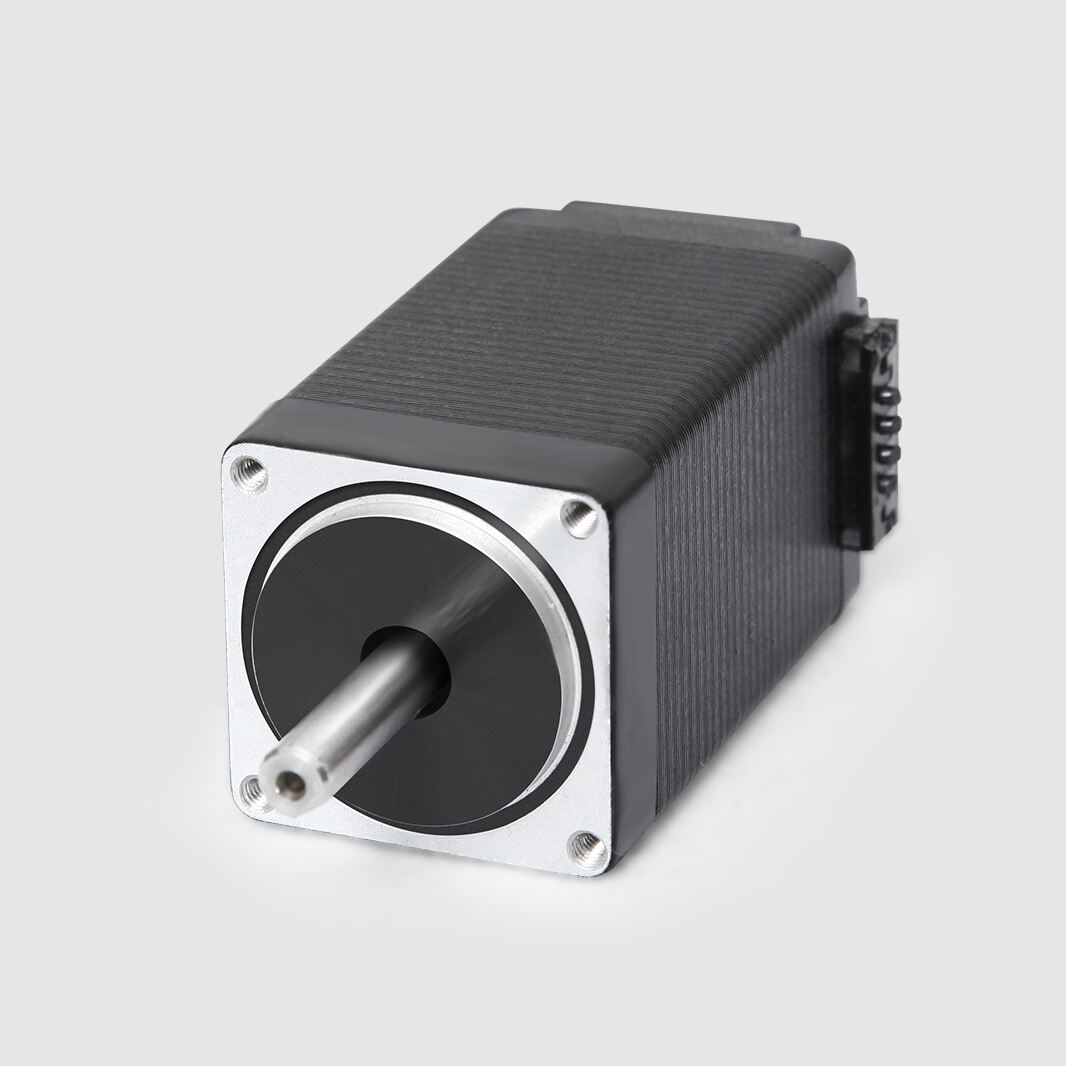

servo stepper

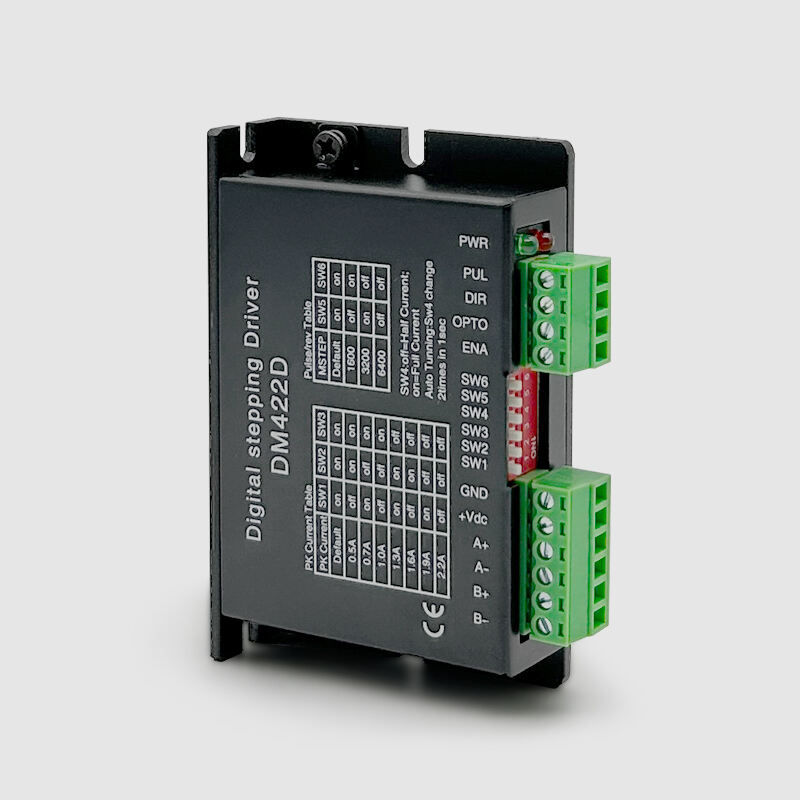

A servo stepper motor represents an innovative fusion of traditional stepper motor technology with advanced servo control capabilities, creating a hybrid solution that delivers exceptional precision and performance in motion control applications. This sophisticated device combines the inherent position accuracy of stepper motors with the closed-loop feedback control systems found in servo motors, resulting in a versatile and reliable automation component. The servo stepper operates by utilizing encoder feedback to monitor actual position and velocity, automatically adjusting motor commands to eliminate step loss and maintain accurate positioning throughout operation. Unlike conventional open-loop stepper systems, the servo stepper continuously monitors performance and compensates for external disturbances, load variations, and mechanical irregularities that could affect positioning accuracy. The core technology incorporates high-resolution encoders that provide real-time feedback to sophisticated control algorithms, enabling the system to detect and correct any deviations from commanded positions instantly. This closed-loop architecture ensures consistent performance across varying operating conditions while maintaining the simple control interface that makes stepper motors popular in automation applications. The servo stepper typically features multiple operating modes, including traditional step-and-direction control for easy integration with existing systems, as well as advanced positioning modes that leverage the servo capabilities for enhanced performance. Modern servo stepper designs often incorporate intelligent drive electronics that automatically tune system parameters, reducing commissioning time and optimizing performance for specific applications. The technology proves particularly valuable in applications requiring high precision, reliability, and ease of use, such as laboratory automation, packaging machinery, textile equipment, and precision manufacturing systems where traditional steppers might lose steps under challenging conditions.