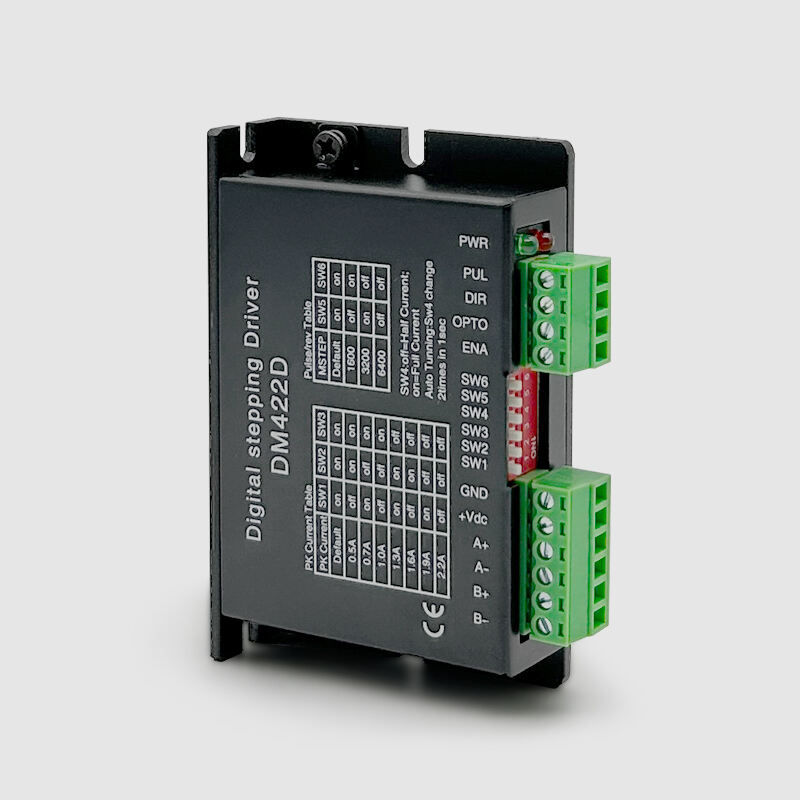

Simplified Integration and Digital Control Compatibility

Modern stepper motor circuits excel in their seamless integration capabilities with contemporary digital control systems, offering unprecedented flexibility for automation engineers and system designers. These circuits feature native compatibility with standard digital communication protocols, including SPI, I2C, UART, and parallel interfaces, enabling direct connection to microcontrollers, single-board computers, and industrial control systems without additional interface hardware. This compatibility eliminates the need for complex analog signal conditioning circuits required by traditional DC motor systems, significantly reducing system complexity and potential failure points. The digital nature of stepper motor circuits allows engineers to implement sophisticated motion profiles through software programming rather than hardware modifications. Acceleration and deceleration ramps can be easily adjusted through parameter changes, enabling system optimization without physical component replacements. Real-time control becomes straightforward as engineers can modify speed, direction, and positioning parameters during operation through simple digital commands. This flexibility proves invaluable in applications requiring dynamic motion pattern adjustments based on sensor feedback or operational requirements. Programming interfaces for stepper motor circuits support high-level commands that abstract complex timing sequences into user-friendly function calls. Engineers can focus on application logic rather than low-level motor control details, accelerating development timelines and reducing debugging complexity. Many stepper motor circuits include built-in motion profiling capabilities that automatically generate smooth acceleration curves, eliminating the need for external motion controllers in many applications. Network connectivity features enable remote monitoring and control of stepper motor circuits through Ethernet, wireless, or industrial fieldbus connections. This capability supports Industry 4.0 initiatives by enabling centralized motion control and data collection from distributed motor systems. Diagnostic information becomes readily available through digital interfaces, providing real-time status updates on motor performance, fault conditions, and operational parameters. Configuration management is simplified through digital parameter storage, allowing engineers to save and restore motor settings for different operational modes or application requirements.