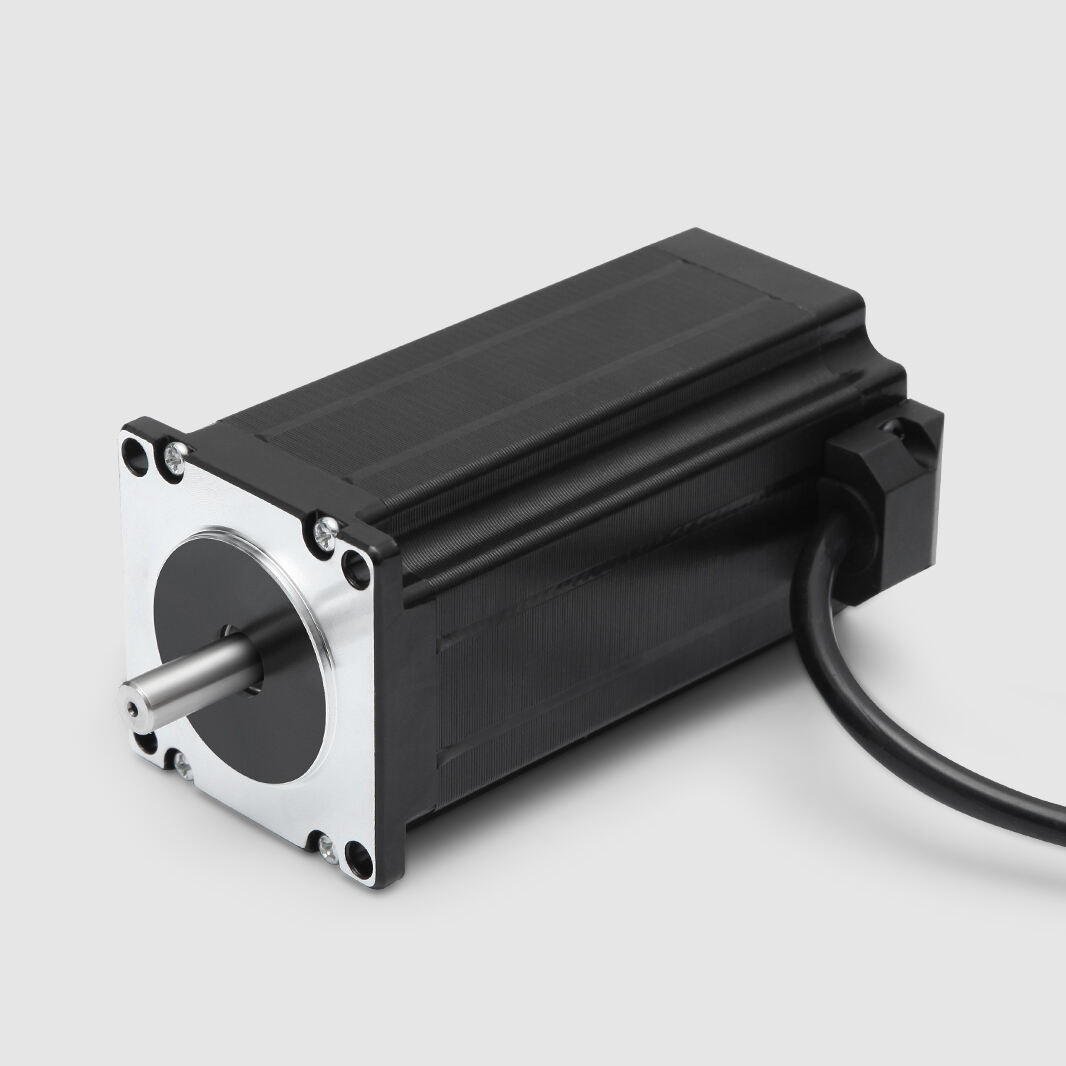

analog servo drive

The analog servo drive is a sophisticated piece of technology designed to convert a control signal into mechanical motion. Its main functions include precise positioning, speed control, and torque regulation, making it an integral component in a variety of automated systems. Technological features of the analog servo drive encompass high bandwidth, low inertia, and rapid response times, enabling it to deliver unmatched performance in dynamic environments. These drives are equipped with feedback mechanisms that ensure accuracy and reliability in their operations. Applications span across robotics, CNC machines, and industrial automation, where precision and efficiency are paramount.