direct drive servo motor price

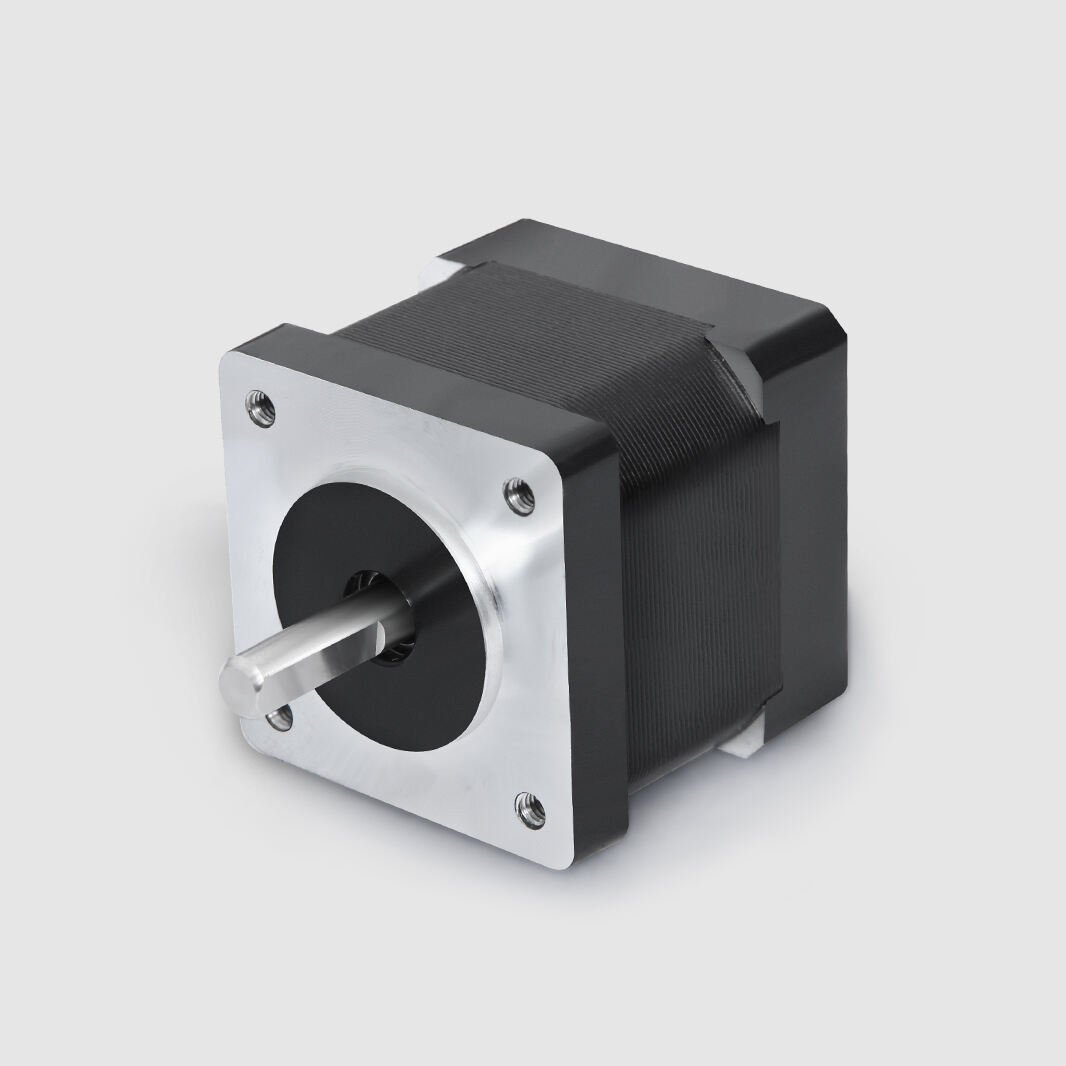

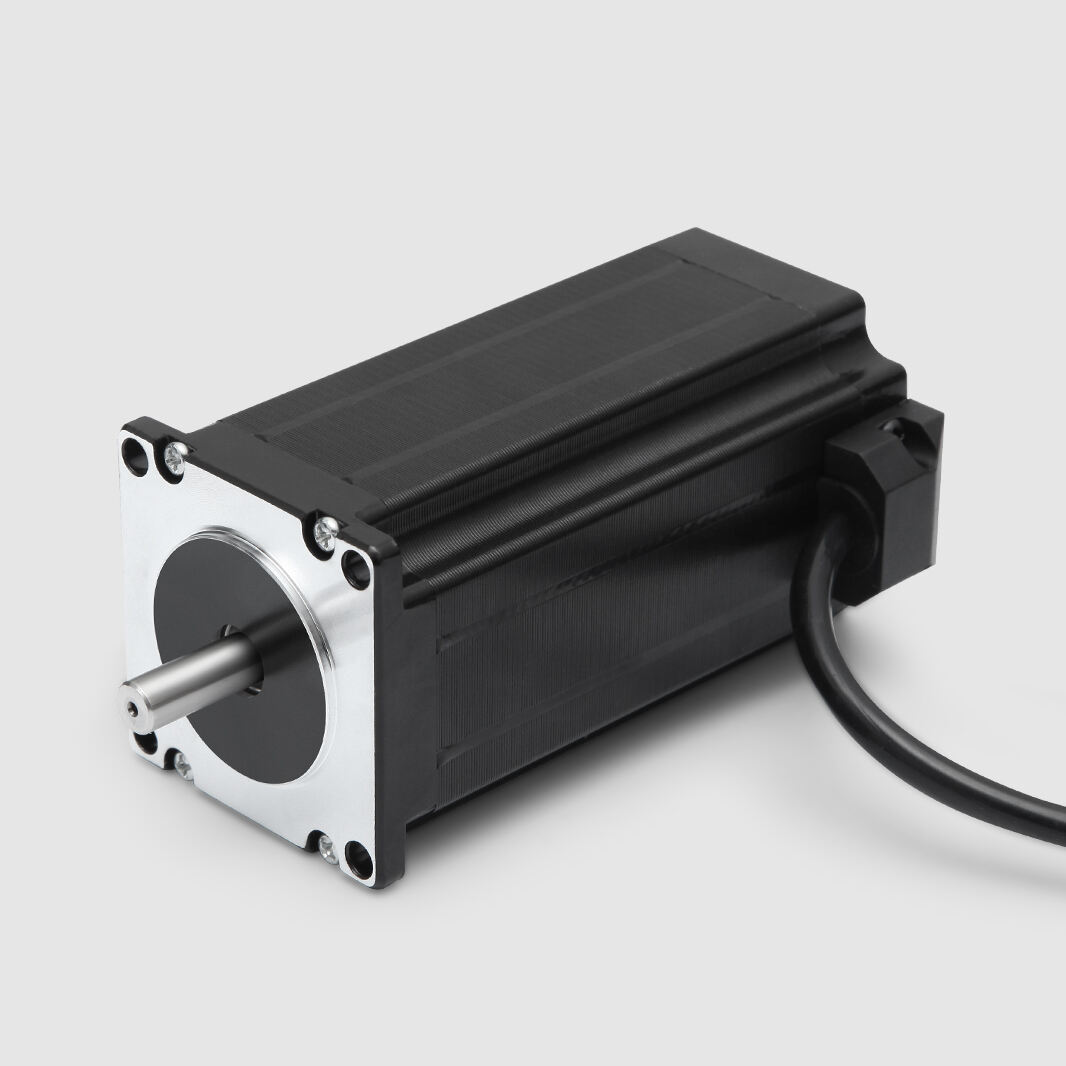

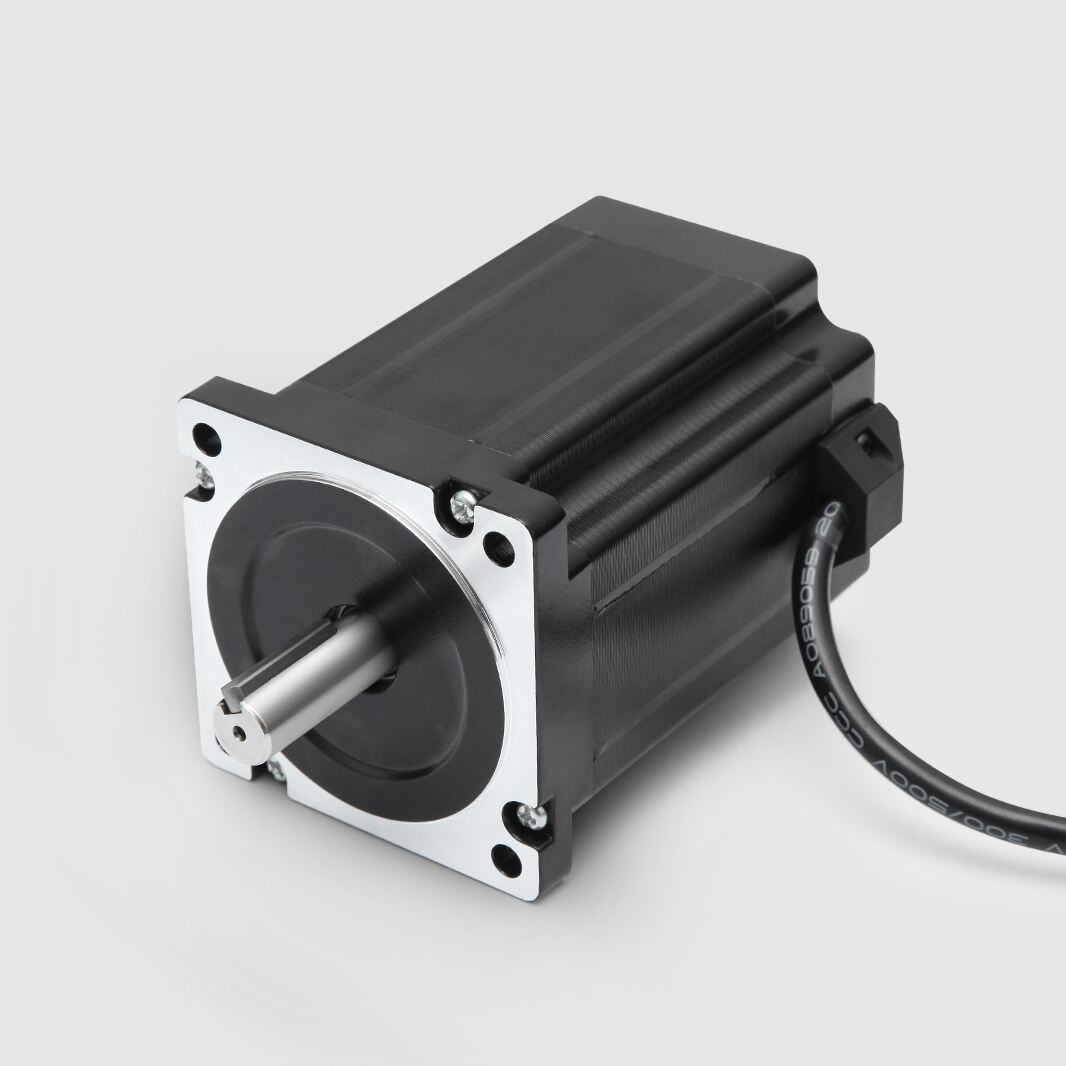

Understanding the direct drive servo motor price involves looking at its core functionalities, technological features, and the wide range of applications it serves. The direct drive servo motor is designed for precision and efficiency, eliminating the need for belts, gears, or other transmission elements that can introduce errors and backlash. This motor provides high torque density and exceptional acceleration capabilities, making it suitable for applications requiring precise positioning and rapid stopping and starting. Technological features include high-resolution feedback devices for accurate control, advanced thermal designs for cooler operation, and built-in intelligence for seamless integration with automation systems. Applications span across robotics, CNC machines, and production lines, where reliability and performance are critical.