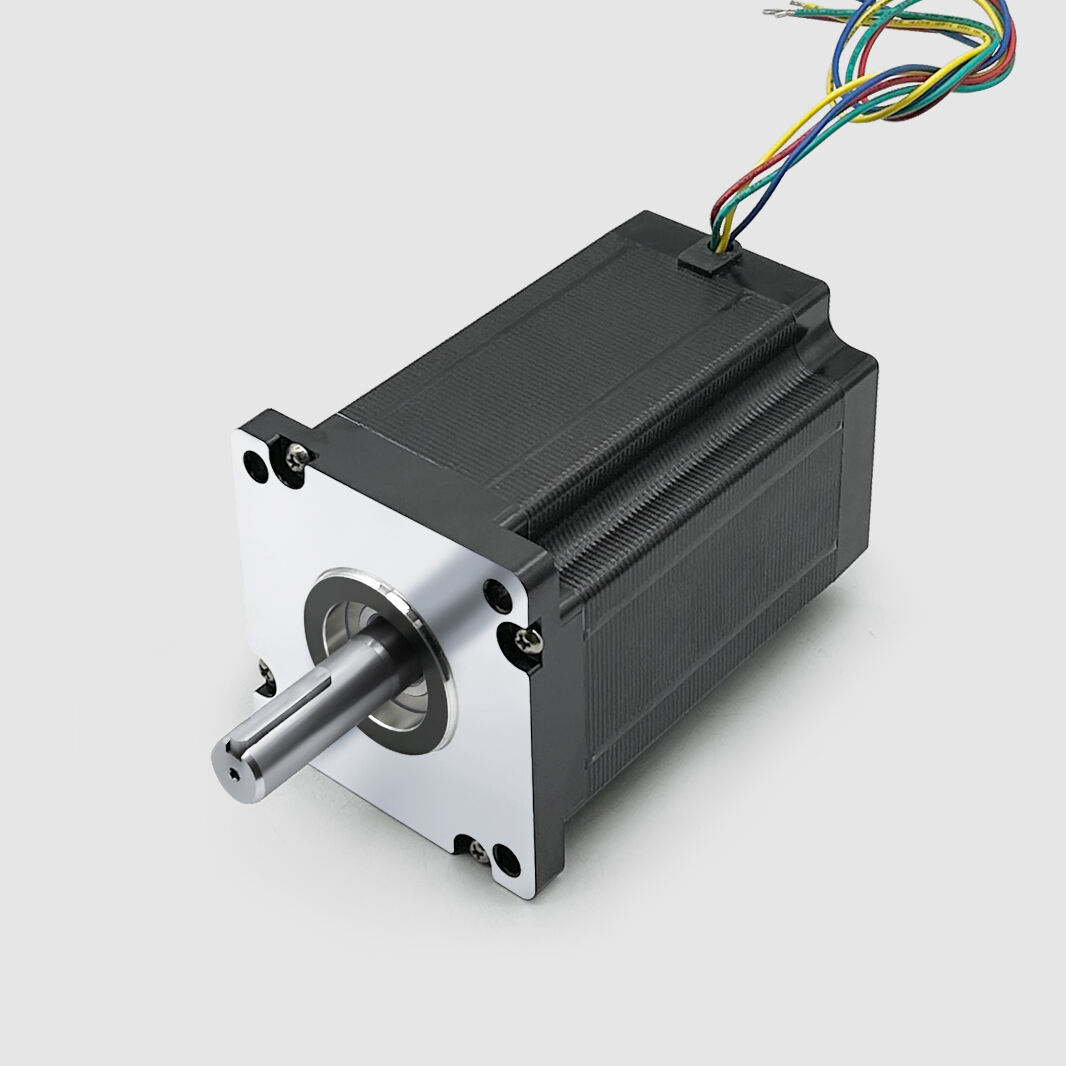

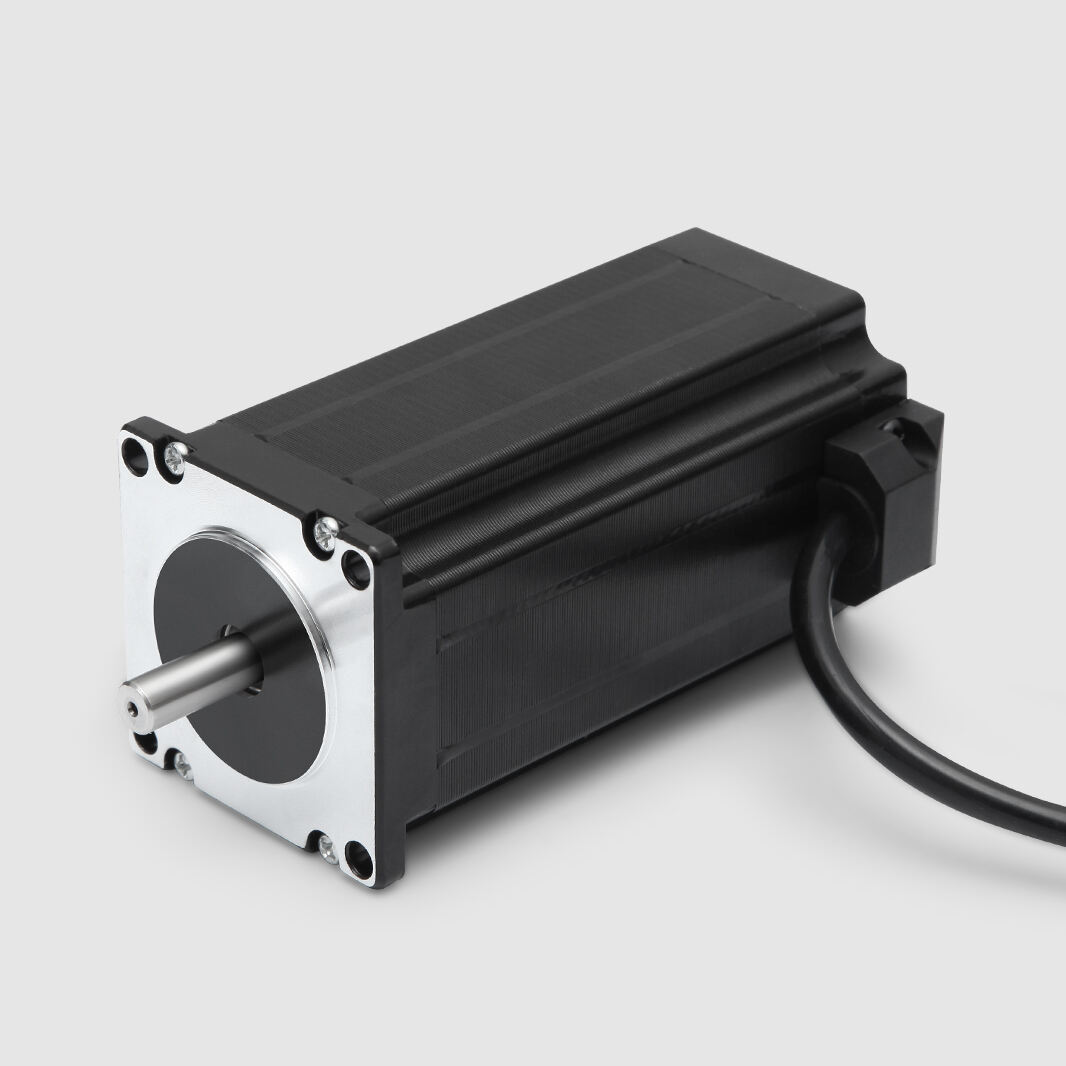

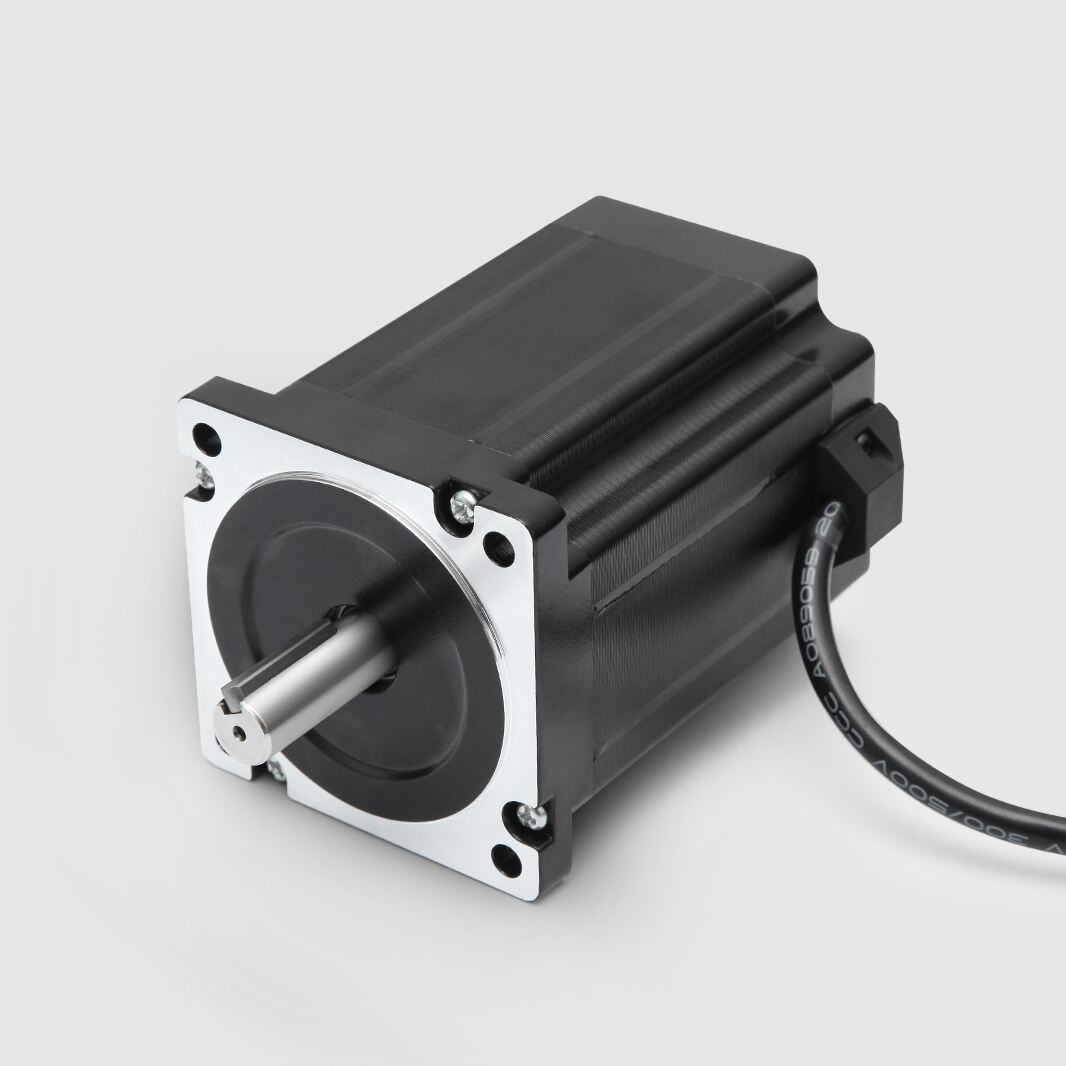

ac servomotor in control system

The AC servomotor in a control system is a precision device designed for accurate positioning and high-speed response. Its main functions include converting electrical energy into mechanical rotation with precise control, allowing for efficient and responsive movement in industrial automation. Technological features of the AC servomotor encompass a robust design with high torque capacity, excellent speed regulation, and minimal maintenance requirements. These motors are equipped with sensors for real-time feedback, ensuring accuracy and reliability in various applications. Common applications range from robotics and CNC machines to industrial automation and conveyor systems, showcasing its versatility and utility in complex control environments.