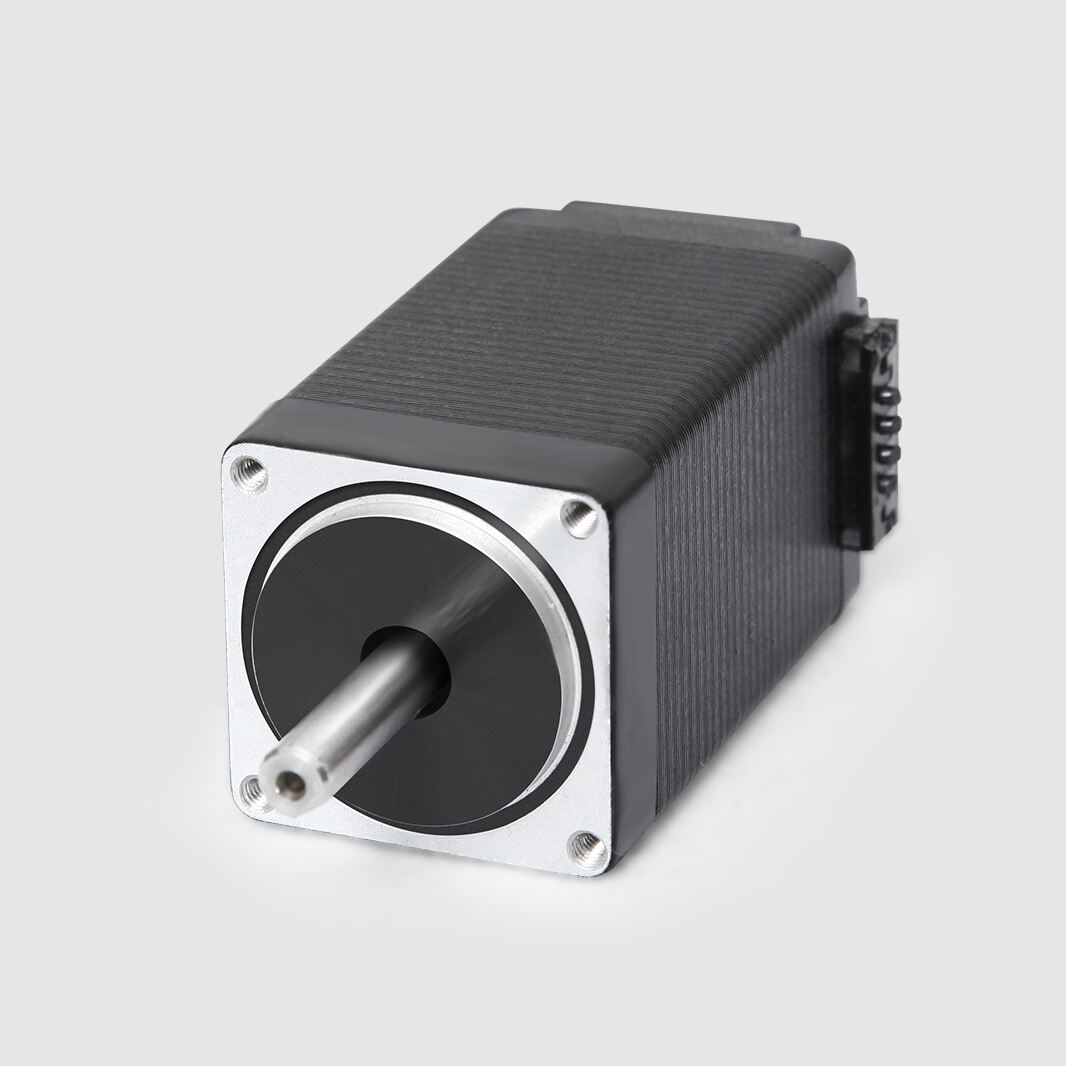

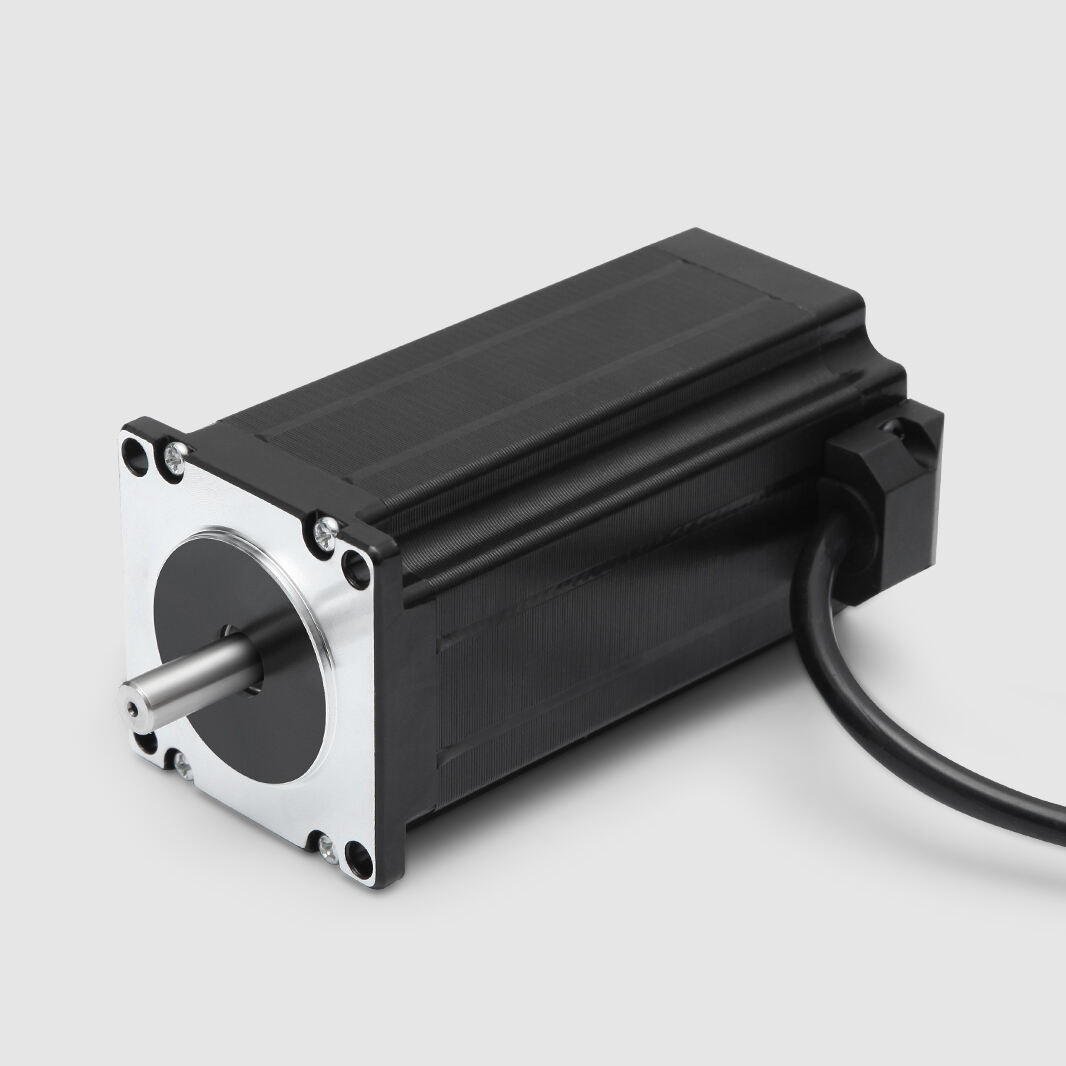

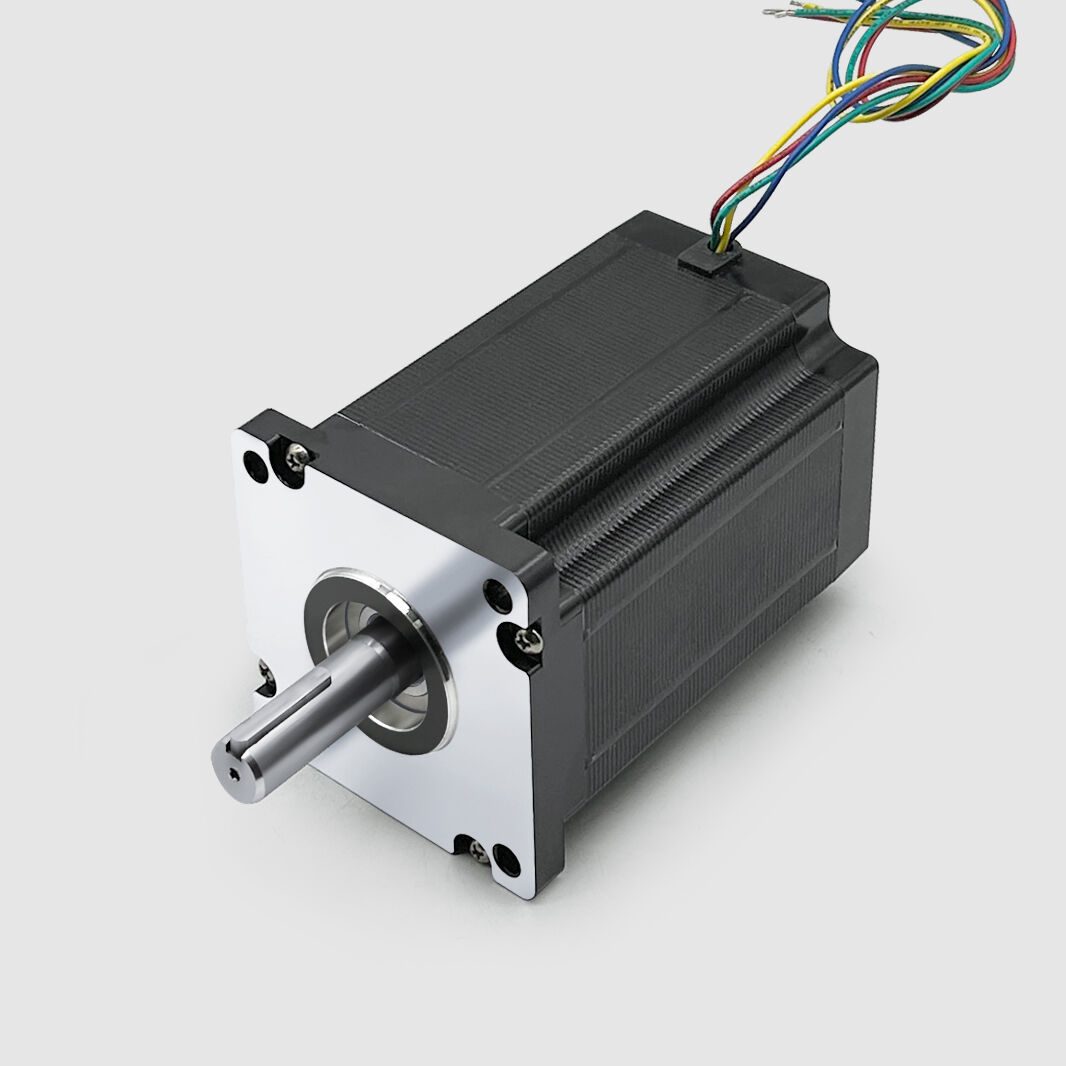

integrated servo motor and drive

An integrated servo motor and drive represents a revolutionary advancement in motion control technology, combining the servo motor and drive controller into a single, compact unit. This sophisticated system eliminates the need for separate components and complex wiring, creating a streamlined solution for precision motion applications. The integrated servo motor and drive features a built-in controller that communicates directly with the motor windings, enabling exceptional responsiveness and accuracy in positioning, speed control, and torque management. The system incorporates advanced digital signal processing capabilities, high-resolution encoders, and intelligent feedback mechanisms that work together to deliver superior performance across various industrial applications. Modern integrated servo motor and drive systems utilize cutting-edge technologies such as field-oriented control algorithms, adaptive tuning capabilities, and real-time performance monitoring to optimize operation under diverse load conditions. The compact design significantly reduces installation complexity while maintaining robust performance characteristics essential for demanding automation tasks. These systems typically feature multiple communication protocols including EtherCAT, CANopen, and Modbus, ensuring seamless integration with existing control networks. The integrated servo motor and drive architecture incorporates sophisticated safety features, thermal protection, and diagnostic capabilities that enhance operational reliability and system longevity. Advanced motion profiling capabilities allow for smooth acceleration and deceleration curves, minimizing mechanical stress and improving overall system efficiency. The built-in intelligence of integrated servo motor and drive systems enables automatic parameter adjustment, reducing commissioning time and simplifying maintenance procedures.