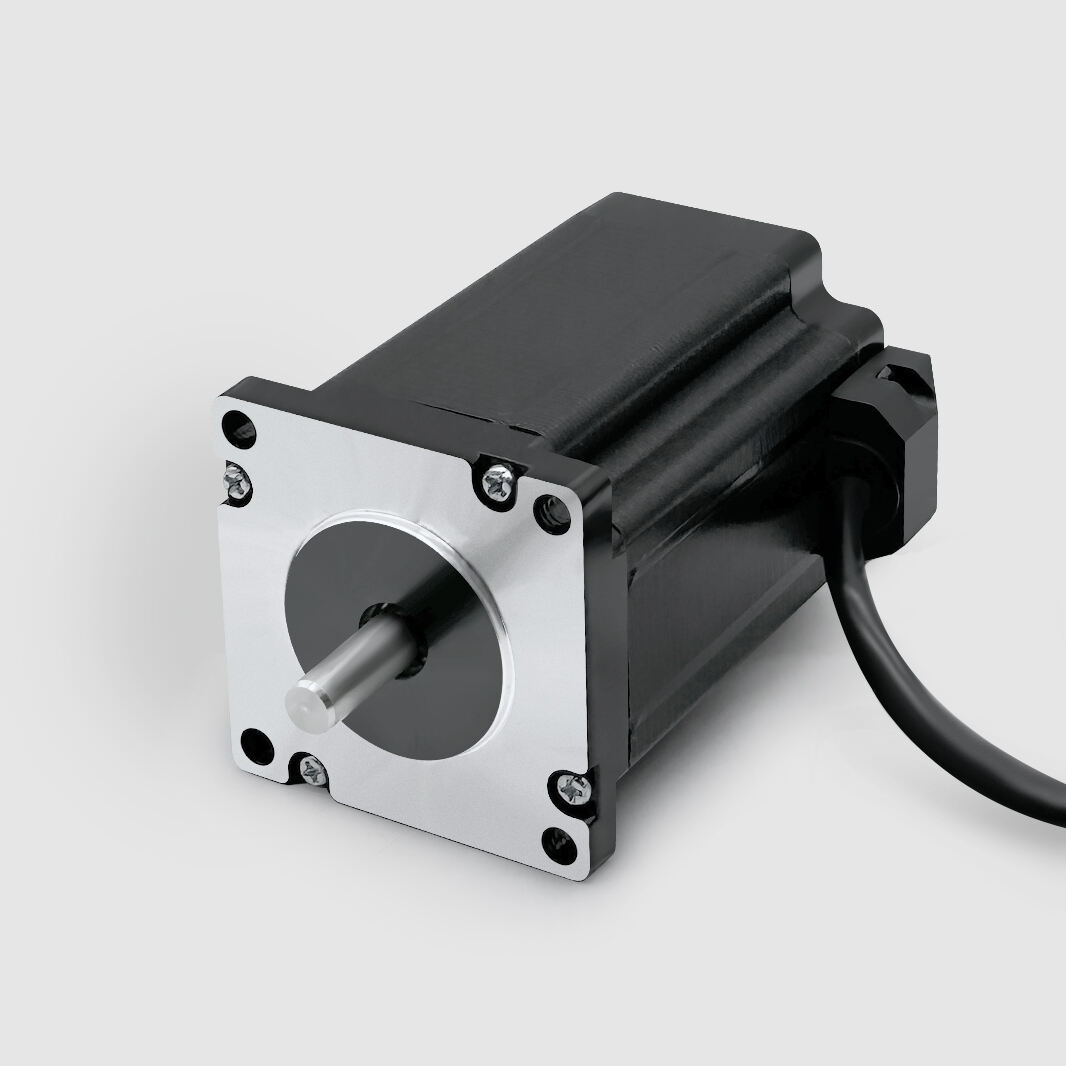

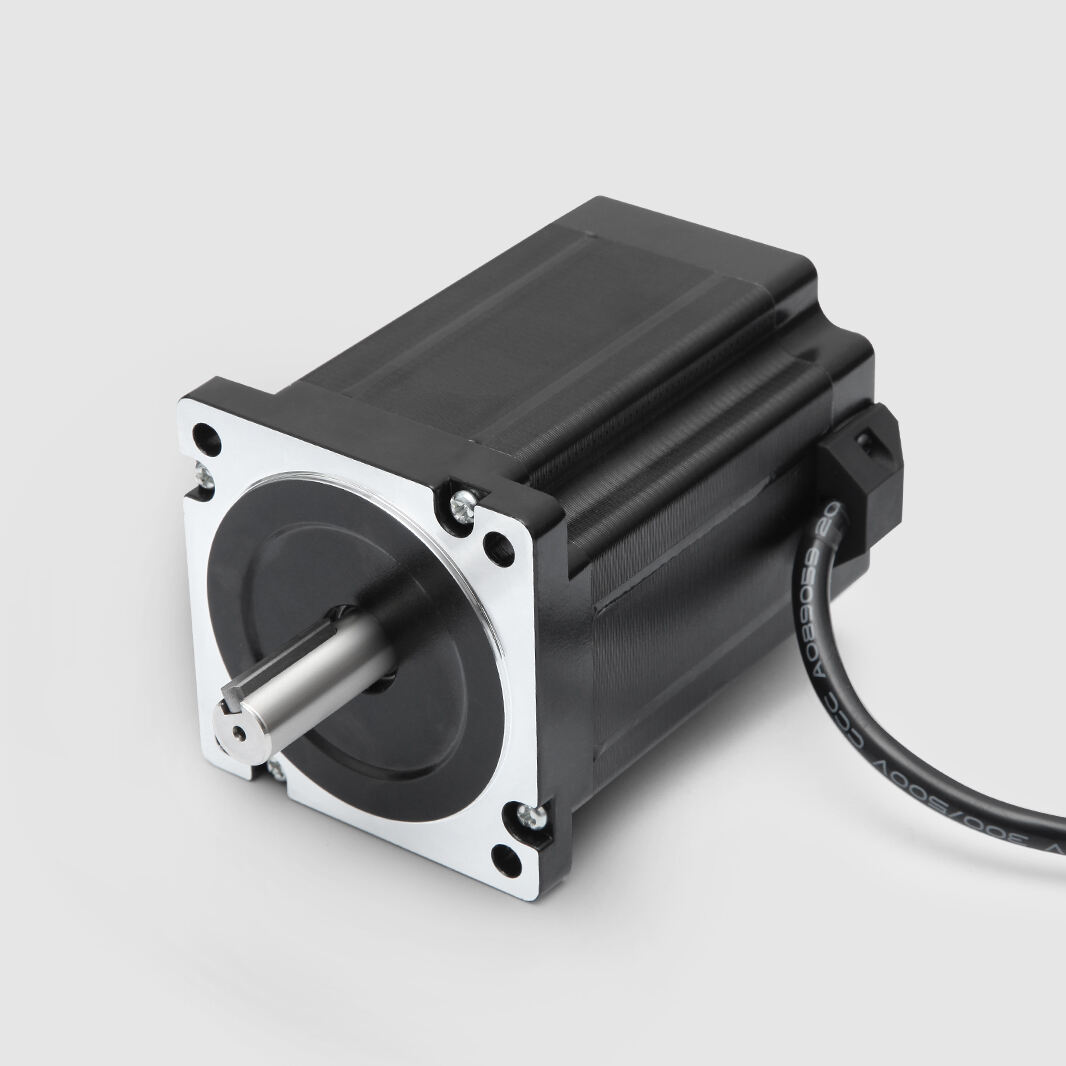

low voltage servo motor

A low voltage servo motor represents a sophisticated electromechanical device designed to deliver precise motion control while operating at reduced voltage levels, typically ranging from 12V to 48V DC. This advanced motor technology combines the fundamental principles of servo control with energy-efficient low voltage operation, making it an ideal solution for applications requiring accurate positioning, speed control, and torque management. The low voltage servo motor incorporates a closed-loop feedback system that continuously monitors and adjusts motor performance to maintain desired operational parameters. The core functionality of a low voltage servo motor revolves around its ability to receive control signals and translate them into precise mechanical movements. These motors feature integrated encoders or resolvers that provide real-time position feedback to the control system, ensuring exceptional accuracy and repeatability. The technological architecture includes a permanent magnet synchronous motor paired with sophisticated electronic control circuits that manage power delivery and motion profiles. Key technological features include high-resolution position feedback systems, advanced PWM control algorithms, and integrated protection circuits that safeguard against overcurrent, overvoltage, and thermal overload conditions. The compact design of low voltage servo motors makes them particularly suitable for space-constrained applications while maintaining robust performance characteristics. These motors demonstrate excellent dynamic response capabilities, allowing for rapid acceleration and deceleration cycles without compromising precision. The low voltage operation significantly reduces electromagnetic interference and simplifies system integration requirements. Applications for low voltage servo motors span across numerous industries, including robotics, automated manufacturing equipment, medical devices, laboratory instrumentation, and precision positioning systems. In robotics applications, these motors provide the precise joint control necessary for articulated robot arms and mobile platform navigation. Manufacturing automation utilizes low voltage servo motors for conveyor systems, pick-and-place operations, and quality inspection equipment. The medical industry benefits from their quiet operation and precise control in surgical instruments, diagnostic equipment, and patient positioning systems.