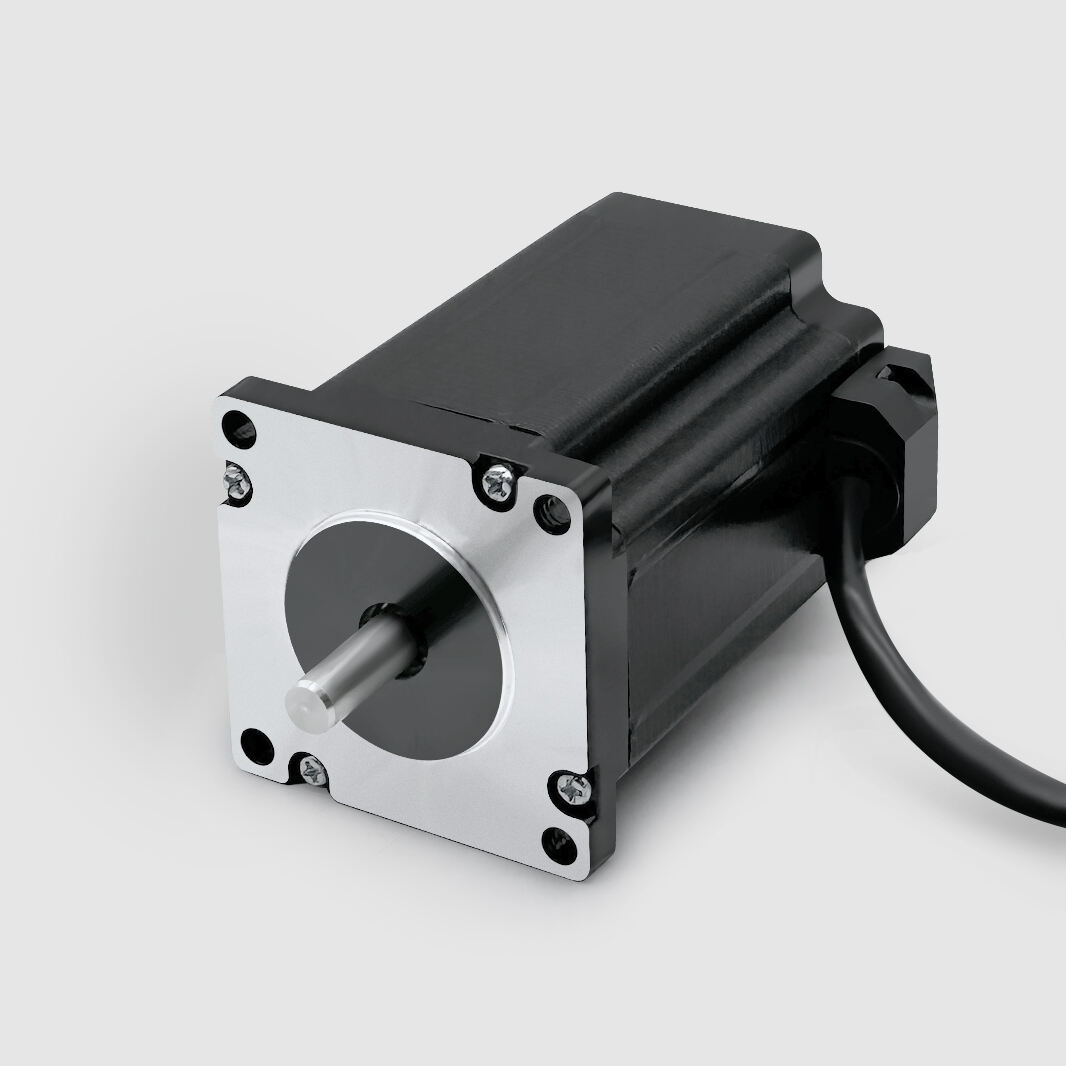

dc servo motor controller

The DC servo motor controller is a sophisticated piece of technology designed to manage the operation of a DC servo motor. Its main functions include precise speed control, position control, and torque control, allowing for highly accurate and efficient motor performance. Technological features of the controller include robust feedback mechanisms, advanced PID algorithms, and compatibility with a wide range of motor types. These features make the DC servo motor controller ideal for applications requiring high precision and reliability, such as robotics, industrial automation, and precision machinery. With its ability to provide real-time adjustments and maintain consistent performance under varying conditions, the controller ensures that the motor operates at peak efficiency and with minimal downtime.