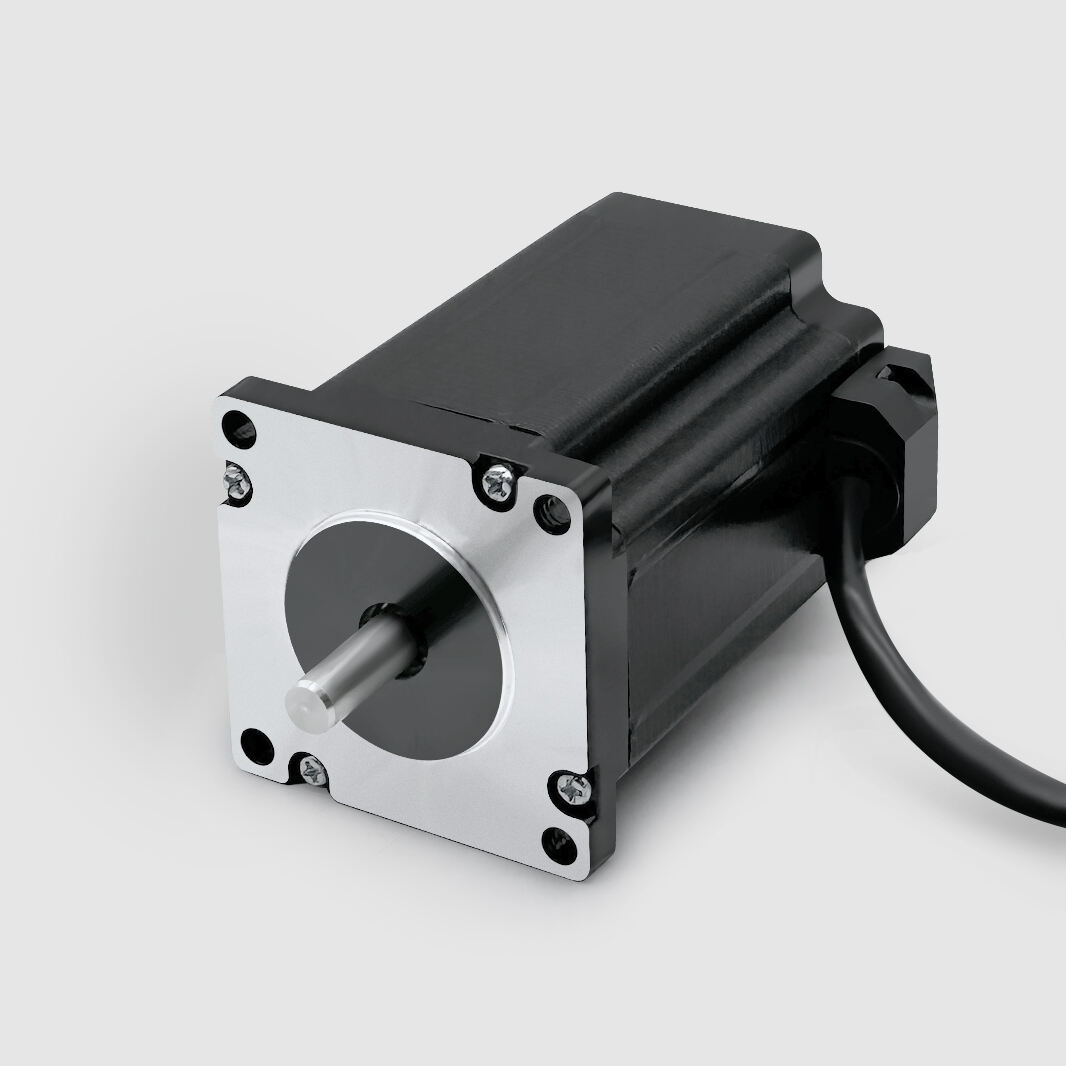

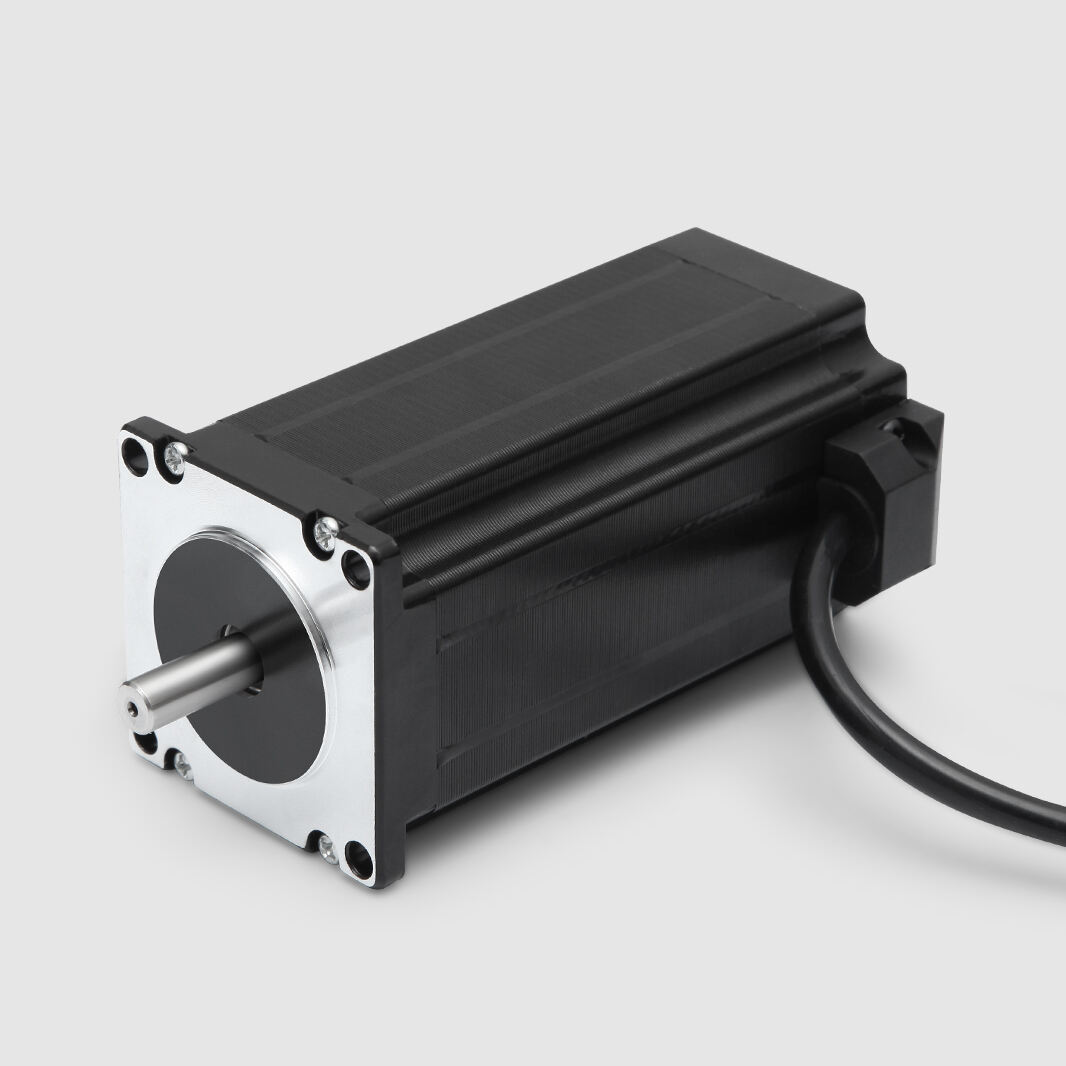

servo motor direct drive

The servo motor direct drive is an innovative technology that streamlines the operation of machinery by eliminating the need for a transmission system. Its main functions include precise positioning, high-speed operation, and variable torque control. Technological features such as closed-loop feedback systems, high torque-to-inertia ratios, and advanced control algorithms enable it to deliver exceptional performance. Applications of the servo motor direct drive are widespread, ranging from industrial automation to robotics and from medical devices to transportation systems. This technology ensures more efficient energy use, reduced wear and tear, and enhanced accuracy in motion control.