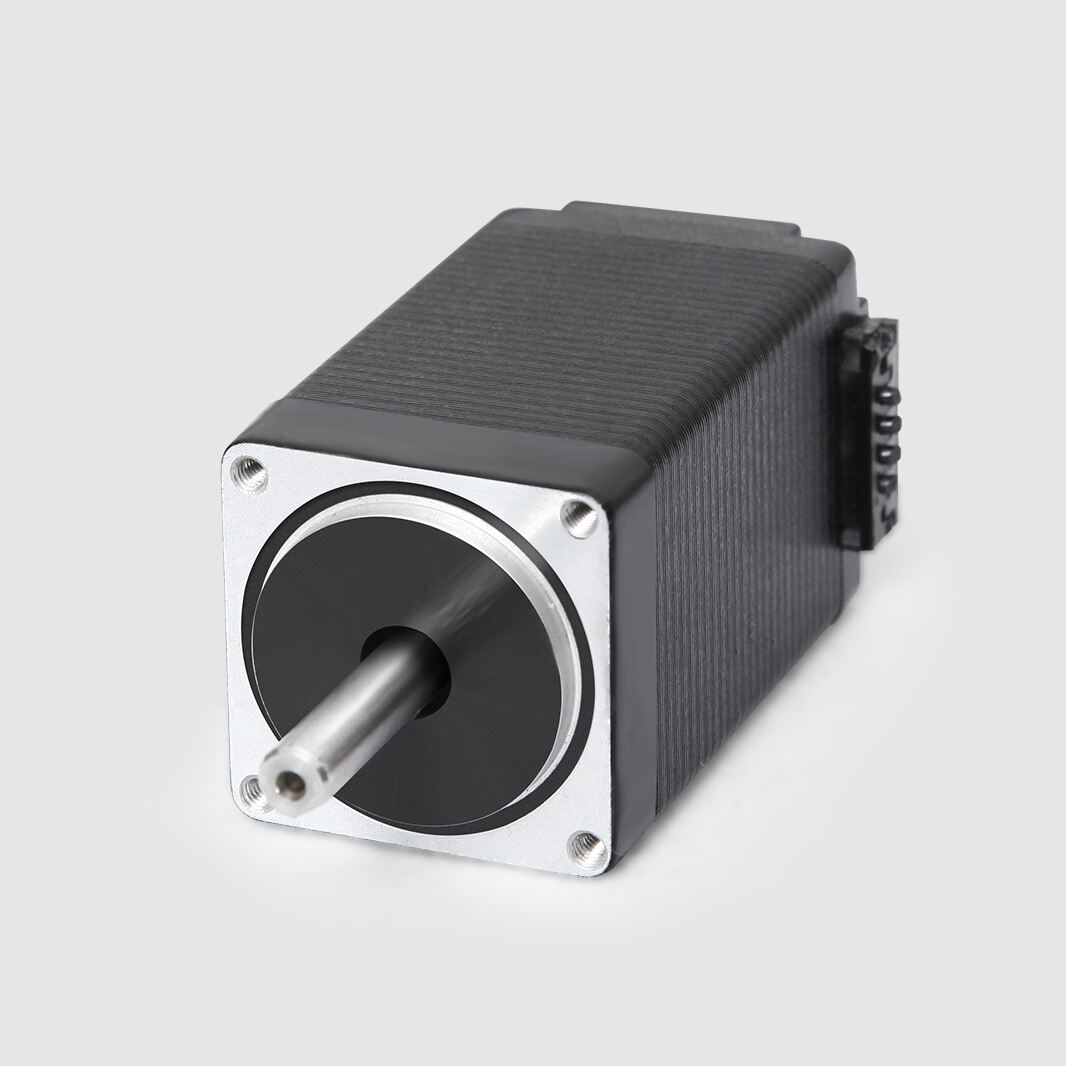

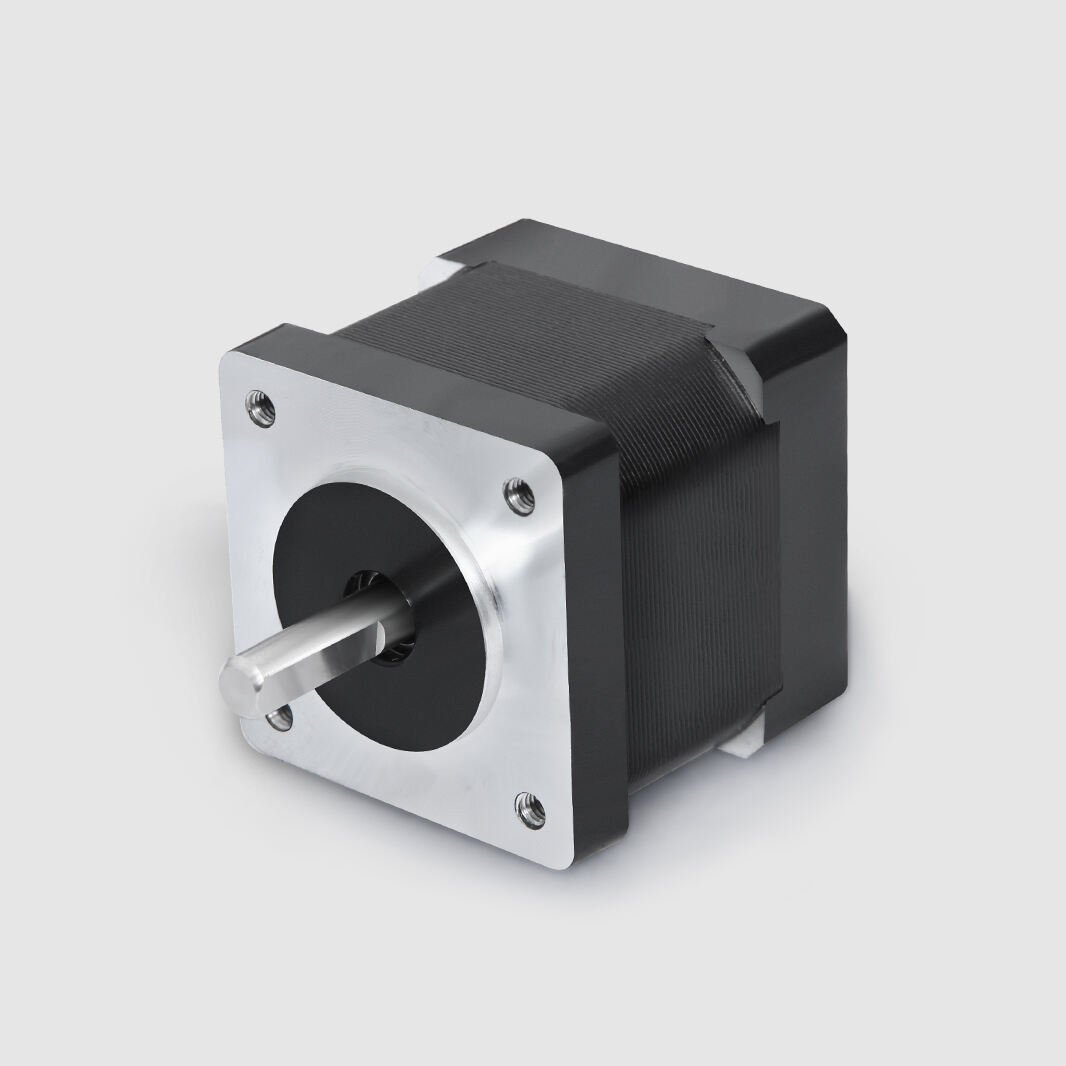

stepper motor without driver

A stepper motor without a driver is a type of brushless electric motor that divides a full rotation into a series of steps. This precise control is achieved through electromagnetic coils that are energized sequentially. The main functions of a stepper motor include accurate positioning, speed control, and high torque at low speeds. Technological features include a simple construction with few moving parts, which reduces wear and tear, and the ability to be controlled with open-loop feedback, doing away with the need for costly and complex feedback systems. These motors find applications in a wide range of industries from robotics to 3D printing, from industrial automation to medical devices, wherever precision and reliability are crucial.