Modern industrial automation relies heavily on precise motor control systems to ensure optimal performance across manufacturing processes. Among the various motor technologies available, stepper motor systems stand out for their unique control characteristics and operational advantages. Understanding how these motors differ from conventional AC and DC motor technologies is crucial for engineers selecting the right motion control solution for their applications. The fundamental differences in control methodology, feedback requirements, and positioning accuracy make stepper motor technology particularly suited for applications demanding precise incremental movement without the complexity of closed-loop feedback systems.

Fundamental Control Architecture Differences

Open-Loop vs Closed-Loop Control Systems

The most significant distinction between stepper motor control and other motor technologies lies in their fundamental control architecture. Traditional DC and AC motors typically operate within closed-loop control systems that require continuous feedback from encoders or sensors to maintain accurate position and speed control. This feedback mechanism constantly monitors the motor's actual position and compares it to the desired position, making real-time adjustments through the controller.

In contrast, stepper motor systems operate primarily in open-loop configurations, where the controller sends predetermined pulse sequences without requiring position feedback. Each pulse corresponds to a specific angular displacement, allowing the motor to move in precise incremental steps. This open-loop operation eliminates the need for expensive feedback devices while maintaining excellent positioning accuracy under normal operating conditions.

The inherent self-synchronizing nature of stepper motor control makes it particularly attractive for applications where simplicity and cost-effectiveness are priorities. However, this advantage comes with limitations, as open-loop systems cannot detect or compensate for missed steps caused by excessive loads or mechanical obstructions.

Pulse-Based Command Structure

Stepper motor controllers utilize discrete pulse trains to generate motion, fundamentally different from the continuous analog or PWM signals used in conventional motor drives. Each pulse represents a fixed angular increment, typically ranging from 0.9 to 1.8 degrees per step in standard configurations. This pulse-based approach provides inherent digital compatibility with modern control systems and programmable logic controllers.

The relationship between pulse frequency and motor speed creates a linear control characteristic that simplifies programming and system integration. Engineers can precisely calculate the required pulse rate to achieve desired speeds, making stepper motor systems highly predictable and repeatable in their operation.

Advanced stepper motor drivers incorporate microstepping capabilities, subdividing each full step into smaller increments to achieve smoother motion and higher resolution. This technique maintains the digital control advantages while significantly improving positioning precision and reducing mechanical resonance effects.

Precision and Accuracy Characteristics

Inherent Positioning Accuracy

Stepper motor technology offers exceptional positioning accuracy without requiring external feedback devices, a significant advantage over conventional motor systems. The mechanical construction of these motors ensures that each step corresponds to a precise angular displacement, typically maintaining accuracy within ±3% of the specified step angle. This inherent precision makes stepper motor applications ideal for positioning tasks where absolute accuracy is more important than dynamic performance.

Unlike servo motors that depend on encoder resolution and controller processing capabilities for positioning accuracy, stepper motor systems derive their precision from the motor's physical construction and the quality of the drive electronics. High-quality stepper motor units can achieve positioning accuracies of ±0.05 degrees or better, making them suitable for demanding applications such as precision manufacturing equipment and scientific instrumentation.

The absence of cumulative positioning errors represents another significant advantage of stepper motor control. Each movement sequence starts from a known position and moves through predetermined increments, eliminating the drift and accumulation errors that can affect other motor technologies over extended operating periods.

Resolution and Microstepping Capabilities

Modern stepper motor controllers incorporate sophisticated microstepping algorithms that significantly enhance resolution beyond the motor's natural step size. Standard full-step operation provides basic positioning resolution, while microstepping techniques can subdivide each step into 256 or more increments, achieving angular resolutions of less than 0.01 degrees.

This microstepping capability allows stepper motor systems to compete with high-resolution servo systems in terms of positioning precision while maintaining the simplicity advantages of open-loop control. The smooth motion characteristics achieved through microstepping also reduce mechanical vibration and acoustic noise, important considerations in precision applications and quiet operating environments.

The relationship between microstepping resolution and torque characteristics requires careful consideration, as higher microstep resolutions typically result in reduced holding torque and increased sensitivity to load variations. Engineers must balance resolution requirements against torque specifications when optimizing stepper motor system performance.

Torque and Speed Performance Comparison

Torque Characteristics Across Operating Ranges

Stepper motor torque characteristics differ significantly from those of conventional AC and DC motors, exhibiting unique performance profiles that influence application suitability. At standstill and low speeds, stepper motor systems provide maximum holding torque, gradually decreasing as operating frequency increases. This torque-speed relationship contrasts sharply with AC induction motors, which develop minimal torque at startup and require acceleration to reach optimal torque production zones.

The holding torque capability of stepper motor units when stationary provides excellent positioning stability without requiring continuous power consumption for brake mechanisms. This characteristic makes stepper motor applications particularly suitable for vertical positioning tasks and applications requiring precise position maintenance during power interruptions.

However, the declining torque characteristics at higher speeds limit the maximum operating velocity of stepper motor systems compared to servo and AC motor alternatives. Applications requiring high-speed operation with consistent torque output may benefit from alternative motor technologies despite the control complexity advantages offered by stepper motor systems.

Dynamic Response and Acceleration Profiles

The step-wise motion characteristics of stepper motor control create unique dynamic response profiles that require specific acceleration and deceleration strategies. Unlike smooth-starting servo motors, stepper motor systems must carefully manage acceleration profiles to prevent step loss and ensure reliable operation throughout the motion sequence.

Ramping algorithms built into modern stepper motor controllers gradually increase pulse frequencies from startup to operating speed, preventing the motor from losing synchronization with the command pulses. These sophisticated control strategies enable stepper motor applications to achieve rapid acceleration while maintaining positioning accuracy and system reliability.

The inherent damping characteristics of stepper motor systems help minimize overshoot and settling time in positioning applications, providing crisp, well-defined motion profiles ideal for indexing and precise positioning tasks. This behavior contrasts with servo systems that may require tuning to achieve optimal dynamic response characteristics.

Control Complexity and Implementation Considerations

Programming and Integration Simplicity

The programming requirements for stepper motor control systems are significantly simpler than those of servo motor alternatives, making them attractive for applications where development time and complexity are important considerations. Basic stepper motor operation requires only pulse and direction signals, easily generated by simple microcontrollers or programmable logic controllers without sophisticated motion control algorithms.

Integration with existing control systems becomes straightforward due to the digital nature of stepper motor command interfaces. Standard pulse train outputs from PLCs or motion controllers can directly drive stepper motor systems without requiring analog interfaces or complex parameter tuning procedures typically associated with servo drive integration.

The deterministic nature of stepper motor response eliminates the need for complex control loop tuning procedures required by servo systems. Engineers can predict system behavior based on pulse timing and frequency calculations, simplifying system design and reducing commissioning time for new installations.

Driver Electronics and Power Requirements

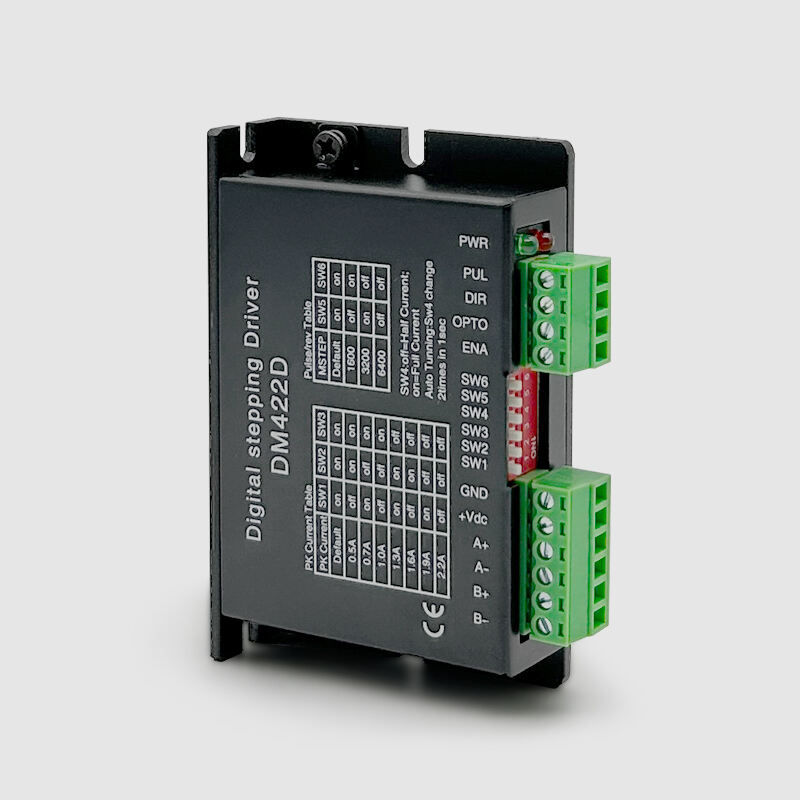

Stepper motor driver electronics incorporate specialized switching circuits designed to energize motor windings in precise sequences, creating the rotating magnetic field necessary for step-wise motion. These drivers differ significantly from conventional motor controllers in their switching patterns and current control strategies, optimized for the unique electrical characteristics of stepper motor windings.

Current regulation techniques employed in modern stepper motor drivers maintain consistent torque output across varying load conditions while minimizing power consumption and heat generation. Chopper-type current control and advanced switching algorithms ensure optimal motor performance while protecting the motor windings from damage due to overcurrent conditions.

Power supply requirements for stepper motor systems typically emphasize current capacity over voltage regulation, as the driver electronics regulate motor current to maintain consistent torque characteristics. This approach differs from servo systems that require precisely regulated voltage supplies and sophisticated power management circuits to achieve optimal performance.

Application-Specific Advantages and Limitations

Ideal Application Scenarios

Stepper motor technology excels in applications requiring precise positioning without the complexity and cost of closed-loop feedback systems. Manufacturing automation equipment, including pick-and-place machines, automated assembly systems, and CNC machinery, benefit significantly from the positioning accuracy and reliability offered by stepper motor control systems.

Medical and laboratory equipment applications leverage the quiet operation and precise positioning capabilities of stepper motor systems for critical functions such as sample positioning, fluid dispensing, and diagnostic equipment operation. The ability to maintain position without continuous power consumption makes stepper motor solutions ideal for battery-powered portable equipment and energy-conscious applications.

Printing and imaging applications utilize stepper motor technology for paper feeding, print head positioning, and scanning mechanisms, where the discrete positioning capability aligns perfectly with the digital nature of these processes. The synchronous relationship between digital commands and mechanical motion eliminates timing uncertainties common in other motor control approaches.

Performance Limitations and Considerations

Despite their advantages, stepper motor systems exhibit certain limitations that must be considered during application selection. The lack of position feedback in open-loop configurations prevents detection of missed steps or mechanical binding conditions, potentially leading to positioning errors in demanding applications or variable load conditions.

Speed limitations inherent in stepper motor design restrict their use in high-velocity applications where servo motors or AC drives would provide superior performance. The torque rolloff characteristics at higher speeds further limit the operational envelope for applications requiring consistent torque output across wide speed ranges.

Resonance phenomena can affect stepper motor performance at specific operating frequencies, causing vibration, noise, and potential step loss. Modern driver electronics incorporate anti-resonance algorithms and microstepping techniques to minimize these effects, but careful system design remains important for optimal performance.

Future Developments and Technology Trends

Advanced Driver Technologies

Emerging developments in stepper motor driver technology focus on enhanced performance through improved current control algorithms and integrated feedback capabilities. Smart drivers incorporating position sensing and closed-loop operation maintain the simplicity advantages of traditional stepper motor control while adding the reliability of feedback-based systems.

Integration of artificial intelligence and machine learning algorithms into stepper motor controllers enables adaptive performance optimization based on operating conditions and load characteristics. These intelligent systems can automatically adjust driving parameters to maintain optimal performance across varying application requirements without manual tuning.

Communication capabilities built into modern stepper motor drivers enable remote monitoring, diagnostics, and parameter adjustment through industrial networks and IoT connectivity. This advancement supports predictive maintenance strategies and remote system optimization, extending the capabilities of traditional stepper motor applications.

Hybrid Control Strategies

Future stepper motor systems increasingly incorporate hybrid control strategies that combine the simplicity of open-loop operation with selective closed-loop capabilities for critical applications. These systems can operate in standard open-loop mode for most positioning tasks while switching to closed-loop control when enhanced accuracy or load verification is required.

Integration with external sensing systems allows stepper motor controllers to adapt their operation based on real-time feedback from vision systems, force sensors, or other measurement devices. This approach maintains the cost and complexity advantages of stepper motor control while addressing the feedback limitations of traditional open-loop systems.

Advanced motion profiles and trajectory planning algorithms optimize stepper motor performance for specific application requirements, automatically generating acceleration profiles that minimize settling time while preventing step loss or mechanical stress.

FAQ

What are the main advantages of stepper motor control over servo motor systems?

Stepper motor control offers several key advantages including open-loop operation that eliminates the need for expensive feedback devices, inherent positioning accuracy without external sensors, simpler programming and integration requirements, and excellent holding torque at standstill. These characteristics make stepper motor systems more cost-effective and easier to implement for many positioning applications, particularly where ultimate speed performance is not the primary concern.

Can stepper motors operate effectively in high-speed applications?

While stepper motors can operate at moderate to high speeds, their torque characteristics decline significantly as speed increases, limiting their effectiveness compared to servo motors in high-speed applications. The maximum practical operating speed depends on the specific motor design, load requirements, and driver capabilities. For applications requiring consistent high-speed performance with full torque output, servo motor systems typically provide superior performance despite their increased complexity.

How do microstepping capabilities enhance stepper motor performance?

Microstepping technology subdivides each full motor step into smaller increments, significantly improving positioning resolution and motion smoothness. This technique can increase resolution by factors of 256 or more, achieving positioning accuracies comparable to high-resolution encoder systems. Additionally, microstepping reduces mechanical vibration, acoustic noise, and resonance effects, making stepper motor operation smoother and more suitable for precision applications and quiet operating environments.

What factors should be considered when selecting stepper motors versus other motor technologies?

Key selection factors include positioning accuracy requirements, speed and torque specifications, control system complexity preferences, cost considerations, and feedback requirements. Choose stepper motors for applications prioritizing positioning accuracy, simplicity, and cost-effectiveness at moderate speeds. Select servo systems for high-speed applications, dynamic performance requirements, or situations where load variations might cause step loss. Consider the total system cost including controllers, feedback devices, and programming complexity when making the final selection decision.

Table of Contents

- Fundamental Control Architecture Differences

- Precision and Accuracy Characteristics

- Torque and Speed Performance Comparison

- Control Complexity and Implementation Considerations

- Application-Specific Advantages and Limitations

- Future Developments and Technology Trends

-

FAQ

- What are the main advantages of stepper motor control over servo motor systems?

- Can stepper motors operate effectively in high-speed applications?

- How do microstepping capabilities enhance stepper motor performance?

- What factors should be considered when selecting stepper motors versus other motor technologies?