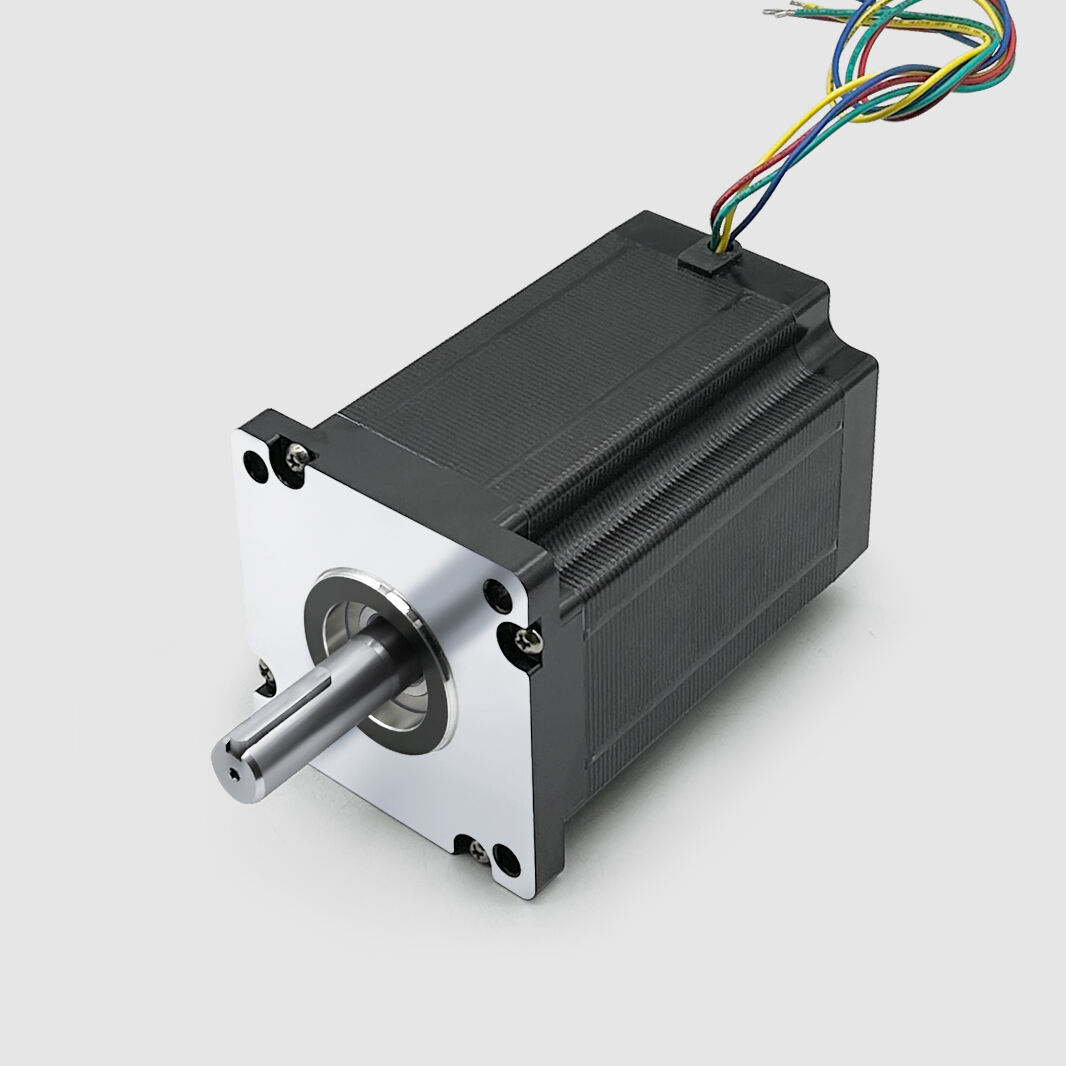

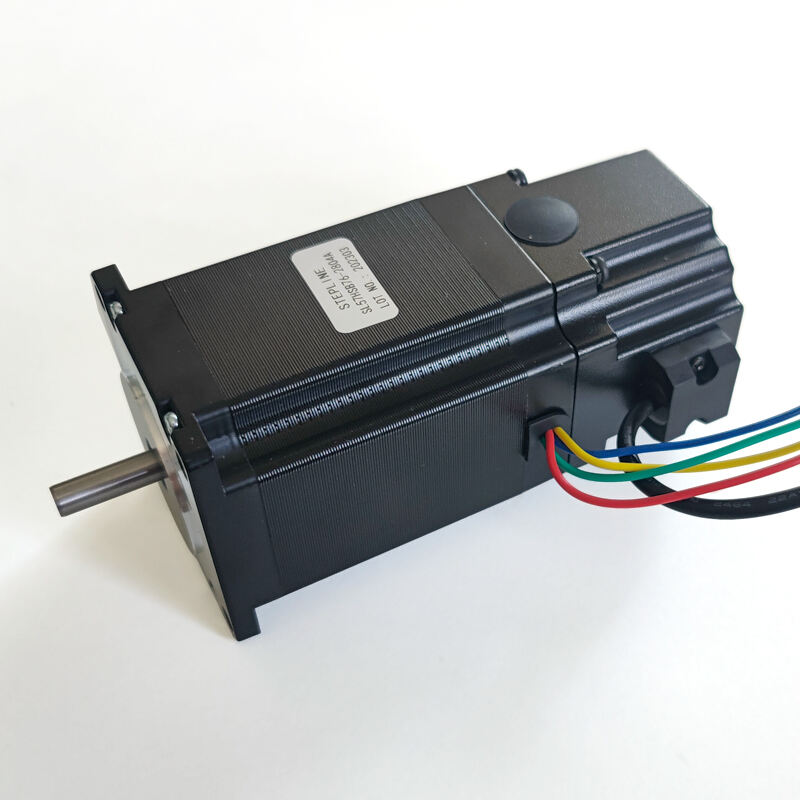

3d printer closed loop stepper

The 3d printer closed loop stepper represents a revolutionary advancement in additive manufacturing precision technology. Unlike traditional open-loop stepper motors that operate blindly without position feedback, the 3d printer closed loop stepper incorporates sophisticated encoder systems that continuously monitor and verify motor position. This intelligent feedback mechanism ensures that each step commanded by the printer's control board is accurately executed, eliminating the common issues of step loss and positional drift that plague conventional stepper systems. The core functionality centers around real-time position verification, where integrated encoders constantly communicate actual motor position back to the driver. When discrepancies arise between commanded and actual positions, the system immediately corrects these errors, maintaining exceptional print accuracy throughout extended manufacturing sessions. Technological features include high-resolution optical or magnetic encoders, advanced driver algorithms that process feedback signals instantaneously, and intelligent error correction protocols. The encoder resolution typically ranges from 1000 to 4000 counts per revolution, providing sub-micron positioning accuracy that surpasses traditional stepper capabilities. The driver electronics feature sophisticated control algorithms that analyze position feedback, motor current, and velocity parameters to optimize performance dynamically. Applications span professional prototyping, medical device manufacturing, aerospace component production, and precision tooling fabrication. Industries requiring tight dimensional tolerances, such as jewelry making, dental prosthetics, and electronic component manufacturing, particularly benefit from this technology. The system excels in applications demanding consistent layer adhesion, precise feature reproduction, and minimal post-processing requirements. Educational institutions utilize these systems for research projects requiring repeatable results, while production facilities rely on them for consistent part quality across large manufacturing runs.