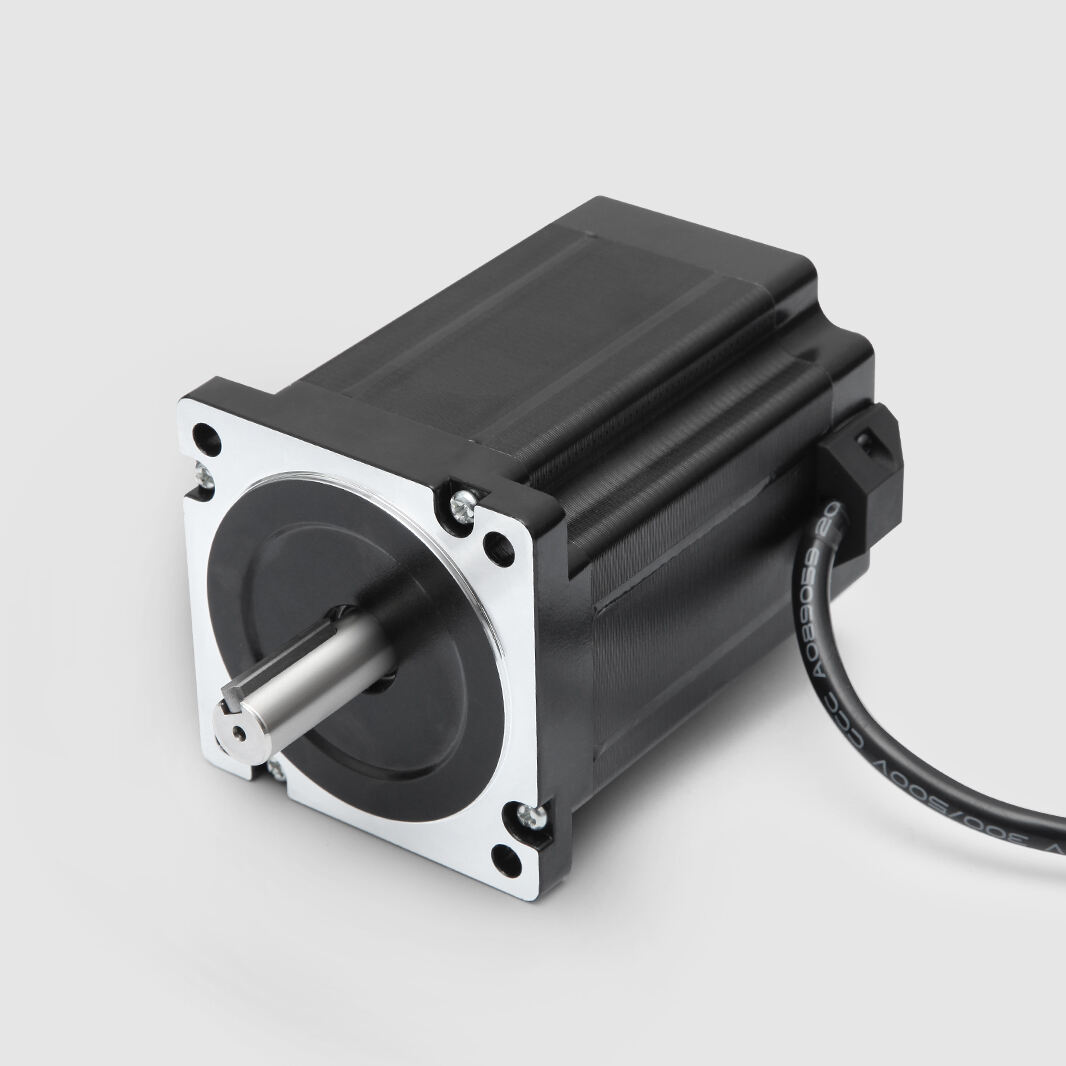

closed loop stepper kit

The closed loop stepper kit is an advanced motor control solution designed for precision and reliability. At its core, this kit ensures highly accurate and consistent motion control by integrating a stepper motor with feedback sensors. The main functions include precise positioning, smooth velocity control, and monitoring of the motor's performance in real-time. Technological features such as adaptive current control and anti-cogging technology are integral to its design, which enhances the motor's efficiency and minimizes vibrations. This makes it suitable for a variety of applications including robotics, CNC machines, 3D printers, and industrial automation where precision and repeatability are crucial.