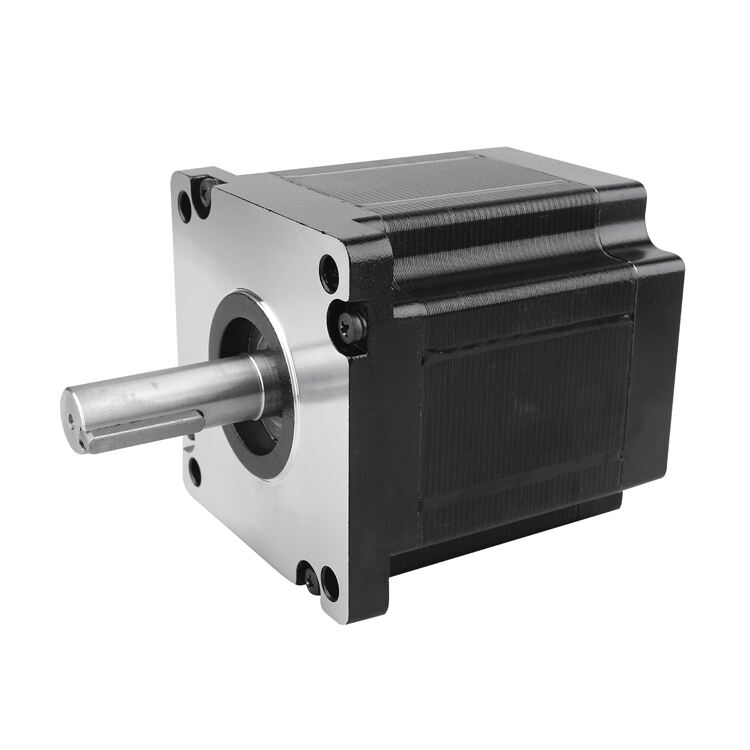

closed loop stepper

The closed loop stepper motor represents a significant advancement in precision motion control technology, combining the simplicity of traditional stepper motors with the accuracy and reliability of closed-loop feedback systems. This innovative motor design integrates an encoder or resolver directly into the stepper motor assembly, creating a sophisticated control system that continuously monitors and adjusts motor performance in real-time. Unlike open-loop stepper motors that operate without position feedback, the closed loop stepper utilizes continuous position monitoring to ensure precise positioning and eliminate common issues such as step loss and resonance. The system works by comparing the commanded position with the actual rotor position through its integrated feedback device, automatically making corrections when discrepancies occur. This feedback mechanism enables the closed loop stepper to maintain exceptional accuracy even under varying load conditions, temperature fluctuations, or mechanical disturbances. The motor controller processes encoder signals instantaneously, adjusting current and timing to compensate for any deviation from the intended position. Modern closed loop stepper systems incorporate advanced algorithms that optimize performance parameters such as torque delivery, speed profiles, and energy efficiency. These motors excel in applications requiring high precision, repeatability, and reliability, making them ideal for CNC machining, 3D printing, robotics, packaging equipment, and laboratory automation. The closed loop stepper technology bridges the gap between traditional stepper motors and servo systems, offering the cost-effectiveness of steppers with enhanced performance characteristics approaching those of servo motors. Manufacturing industries particularly benefit from the consistent positioning accuracy and reduced maintenance requirements that closed loop stepper motors provide. The integration of digital communication protocols allows seamless connectivity with modern automation systems, enabling remote monitoring, diagnostics, and parameter adjustment. This technological advancement has revolutionized precision motion applications by delivering superior performance while maintaining the inherent advantages of stepper motor technology.