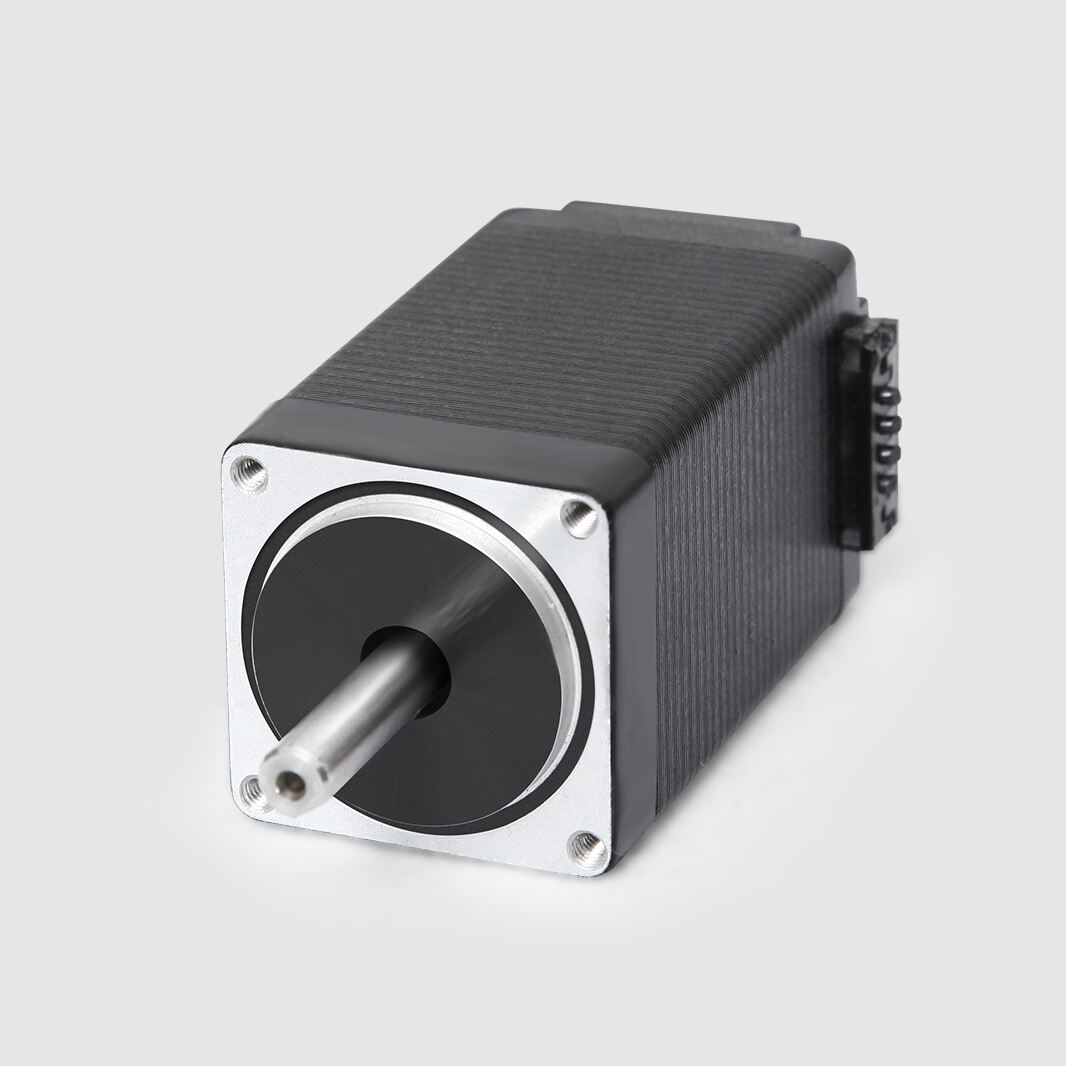

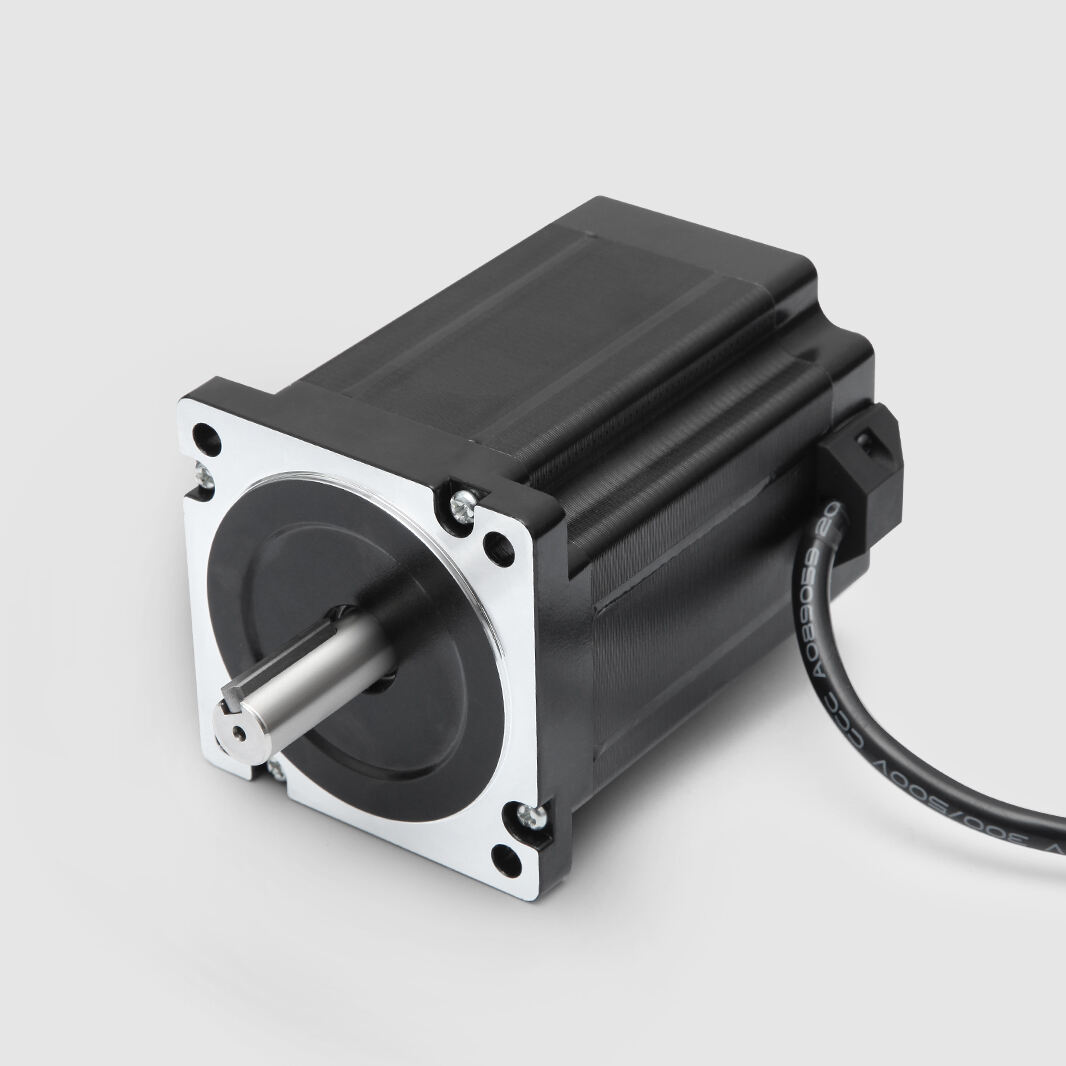

closed loop stepper motor kit

A closed loop stepper motor kit represents a revolutionary advancement in motion control technology, combining the precision of traditional stepper motors with sophisticated feedback systems for enhanced performance. This comprehensive solution integrates a stepper motor, encoder, driver controller, and necessary accessories to create a complete motion control package. The closed loop stepper motor kit operates by continuously monitoring the actual rotor position through encoder feedback and comparing it to the commanded position, automatically correcting any deviations to maintain exceptional accuracy. The system incorporates advanced algorithms that detect missed steps, stalling conditions, and load variations, enabling real-time adjustments to ensure optimal performance across diverse operating conditions. These kits typically include high-resolution encoders capable of providing thousands of pulses per revolution, delivering position feedback with remarkable precision. The integrated driver features intelligent control circuits that process encoder signals and implement corrective actions within microseconds, preventing accumulation of positioning errors. Modern closed loop stepper motor kits support various communication protocols including RS485, CAN bus, and Ethernet, facilitating seamless integration with programmable logic controllers and computer-based control systems. The technology addresses fundamental limitations of traditional open-loop stepper systems, such as resonance issues, torque loss at higher speeds, and potential step loss under excessive loads. Applications span numerous industries including CNC machining, 3D printing, robotics, automated packaging, medical equipment, and laboratory instrumentation. The closed loop stepper motor kit excels in scenarios requiring precise positioning, smooth operation across variable speeds, and reliable performance in demanding environments. These systems offer programmable acceleration and deceleration profiles, microstepping capabilities for smoother motion, and configurable protection features including overcurrent, overvoltage, and overtemperature safeguards. The compact design philosophy ensures easy installation while maintaining robust performance characteristics essential for industrial automation applications.