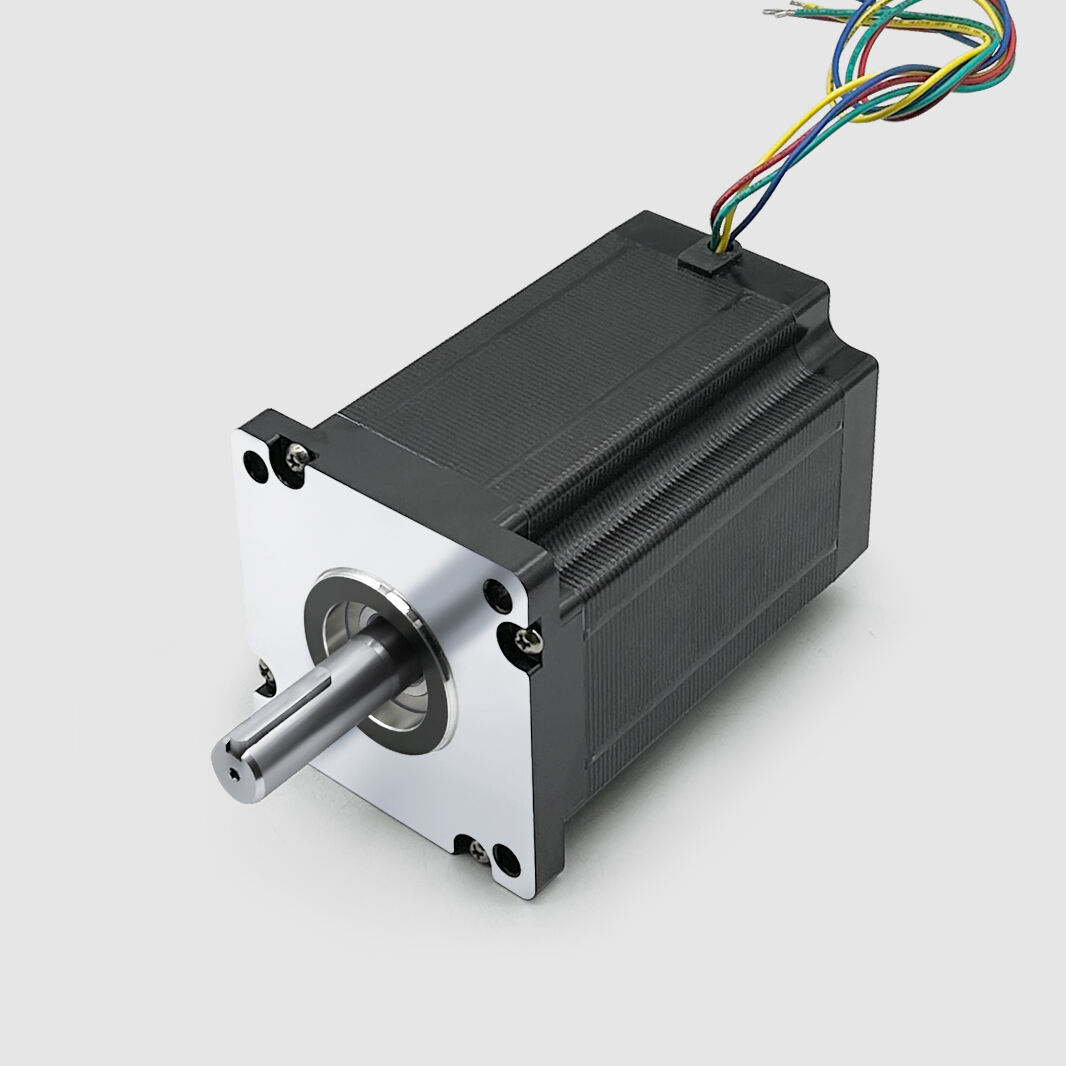

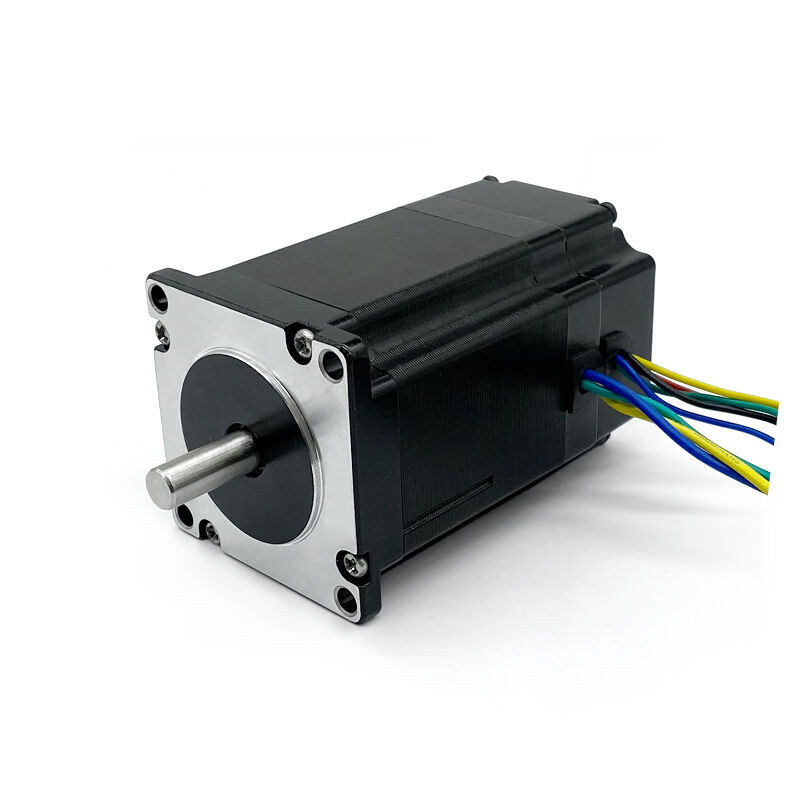

bldc motor high rpm

The bldc motor high rpm represents a cutting-edge advancement in electric motor technology, designed to deliver exceptional performance at elevated rotational speeds. These brushless direct current motors operate without physical brushes, utilizing electronic switching to control the motor's commutation process. The primary functions of a bldc motor high rpm include providing precise speed control, generating high torque-to-weight ratios, and maintaining consistent performance across varying load conditions. These motors excel in applications requiring sustained high-speed operation while maintaining energy efficiency and reliability. The technological features of bldc motor high rpm systems incorporate advanced permanent magnet rotors, sophisticated electronic speed controllers, and precision-engineered stator windings that enable smooth operation at thousands of revolutions per minute. The absence of brushes eliminates friction-related wear, significantly extending operational lifespan compared to traditional brushed motors. Modern bldc motor high rpm units feature integrated sensors that provide real-time feedback on rotor position, enabling precise control algorithms that optimize performance and efficiency. These motors typically employ neodymium permanent magnets that generate strong magnetic fields, contributing to their compact size and high power density. The electronic commutation system ensures optimal timing of current switching, maximizing torque output while minimizing energy losses. Applications for bldc motor high rpm technology span numerous industries, including aerospace systems, medical equipment, robotics, automotive components, and industrial automation. In drone propulsion systems, these motors provide the rapid response and sustained high-speed operation necessary for stable flight control. Medical centrifuges utilize bldc motor high rpm units to achieve the precise rotational speeds required for sample separation processes. The automotive industry incorporates these motors in electric vehicle cooling systems, fuel pumps, and auxiliary drives where reliability and efficiency are paramount. Manufacturing equipment benefits from the precise speed control capabilities, enabling consistent product quality in high-speed production lines.