How Do You Choose the Right Stepper Motor Driver for Your Project?

Understanding Stepper Motor Drivers Basics

What Is a Stepper Motor Driver?

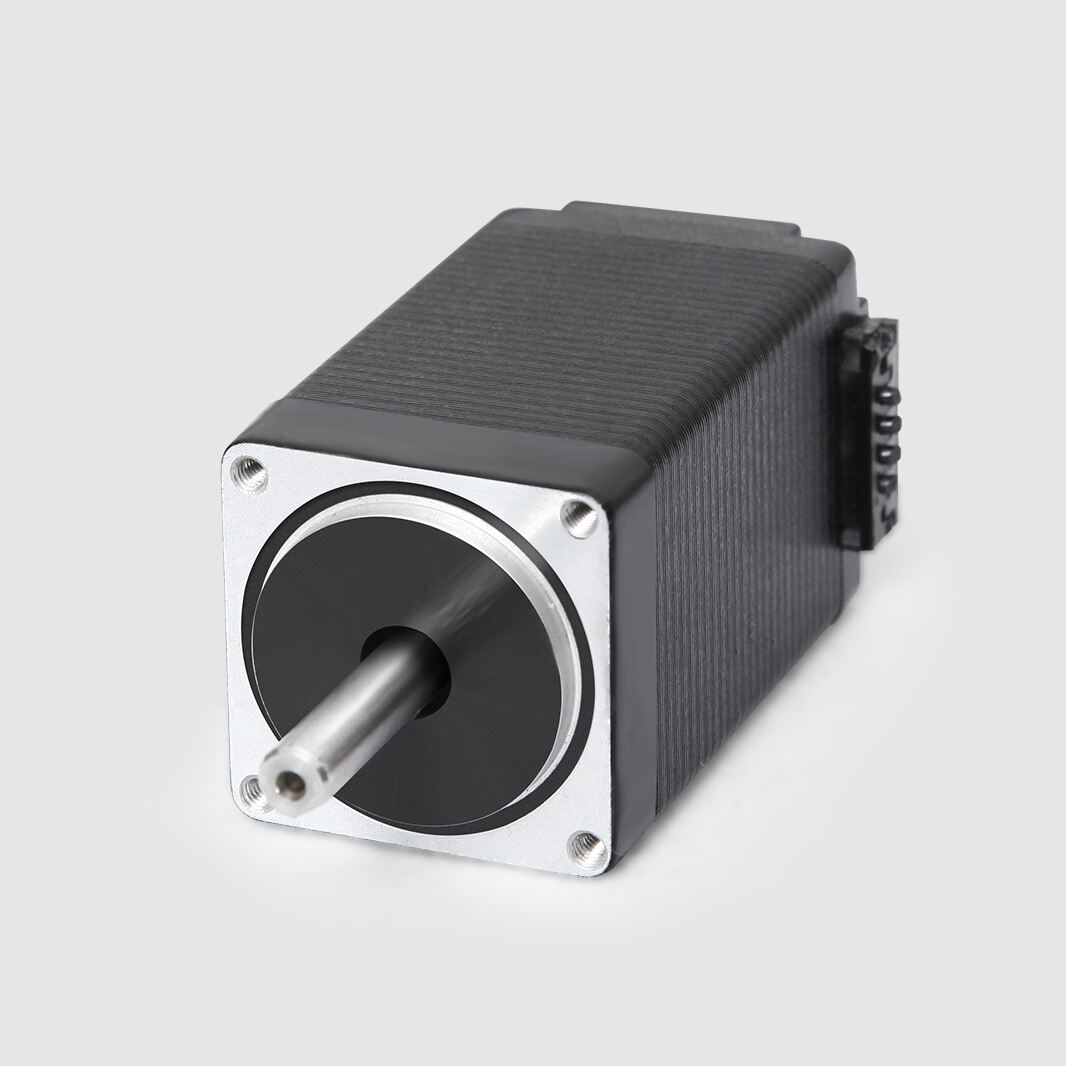

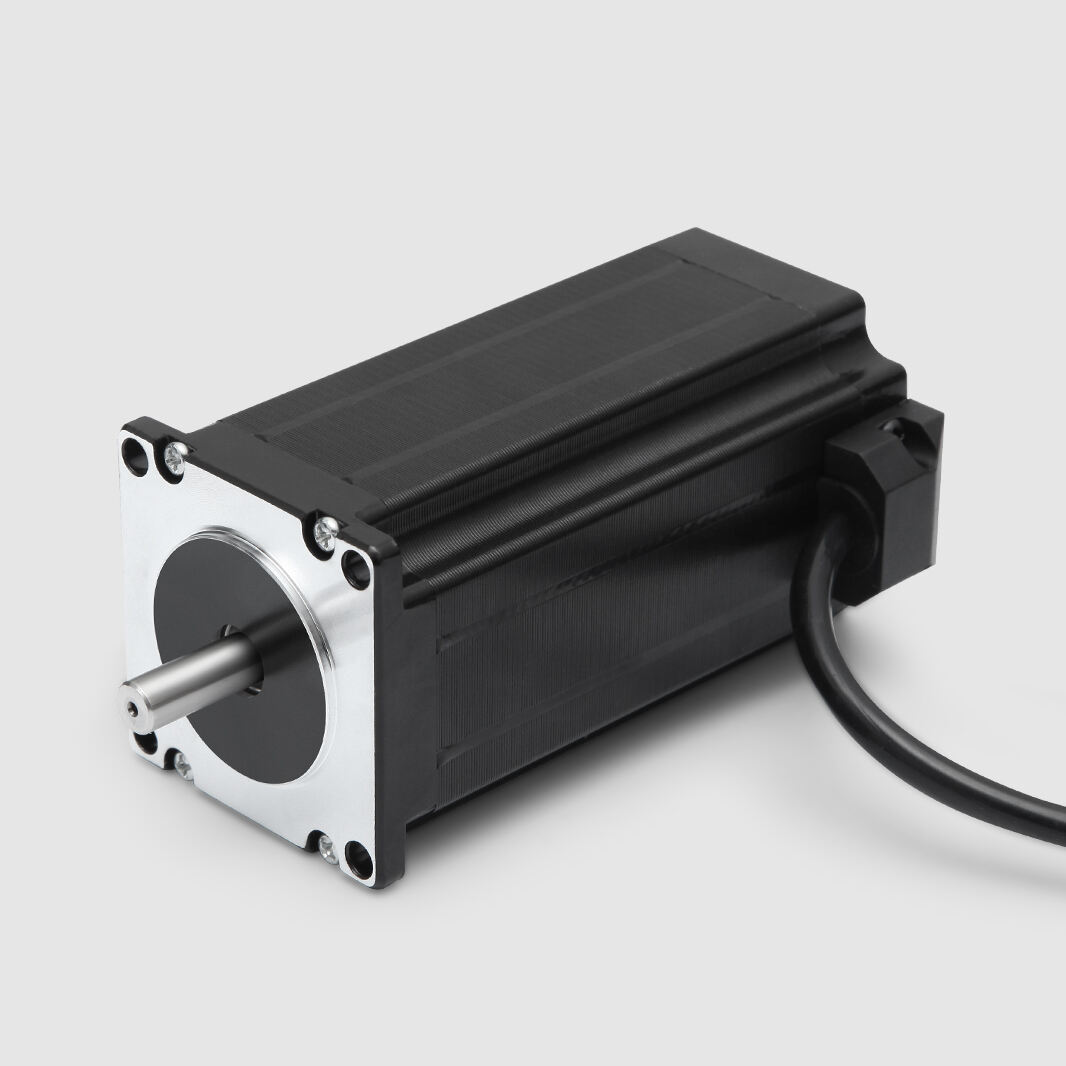

Stepper motor drivers serve as important electronic devices that manage how stepper motors operate, allowing them to move precisely across many different applications. These...

View More