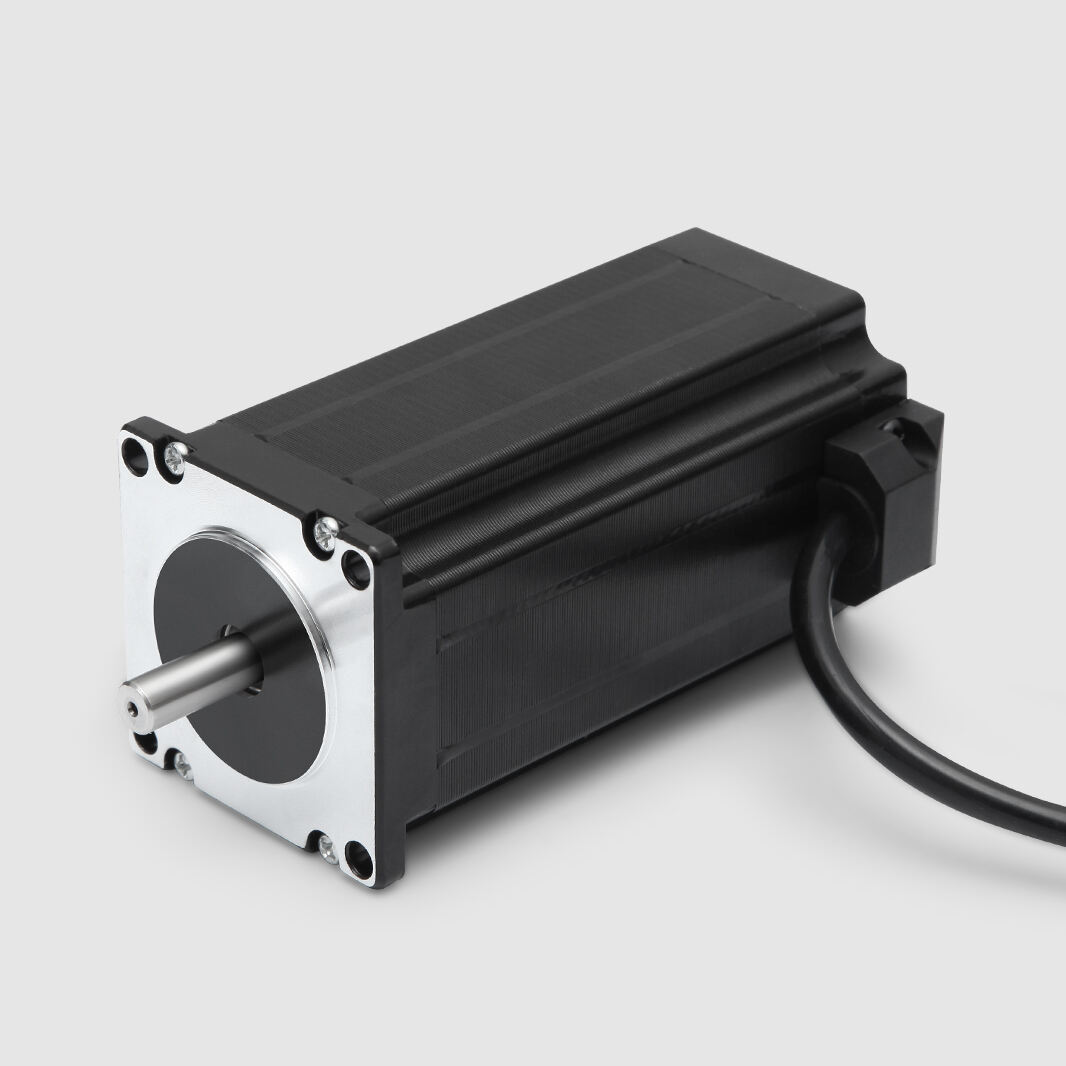

hybrid servo motor

The hybrid servo motor represents the pinnacle of precision engineering, designed to deliver unparalleled performance in a variety of industrial settings. This innovative motor combines the best features of both AC and DC motors, offering exceptional speed control, high torque, and low inertia. Its main functions include precise positioning, rapid acceleration and deceleration, and consistent speed control under varying load conditions. Technological features such as brushless design, high-resolution feedback sensors, and advanced control algorithms contribute to its superior performance. Applications range from robotics and CNC machinery to conveyor systems and packaging equipment, making it a versatile solution for a multitude of industries.