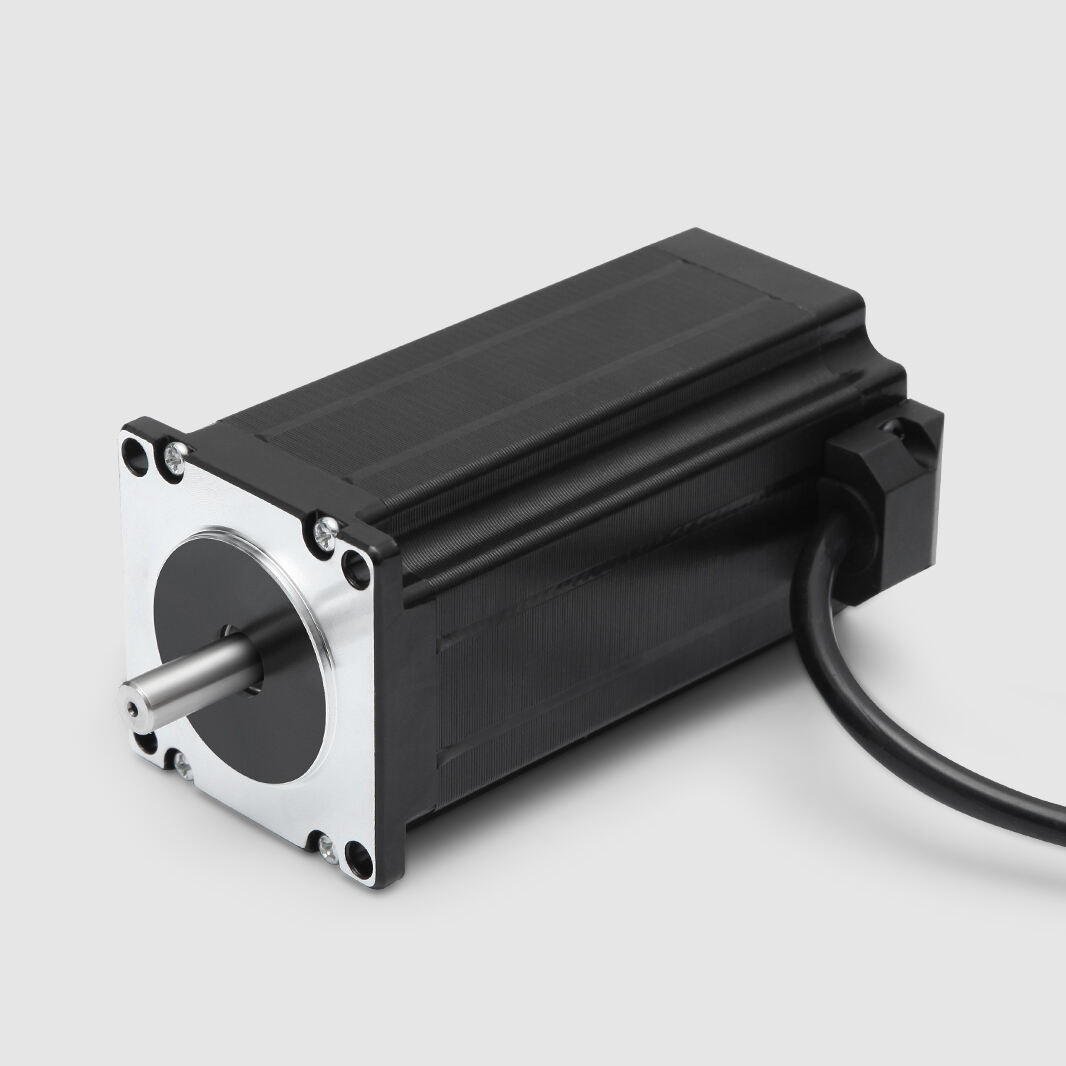

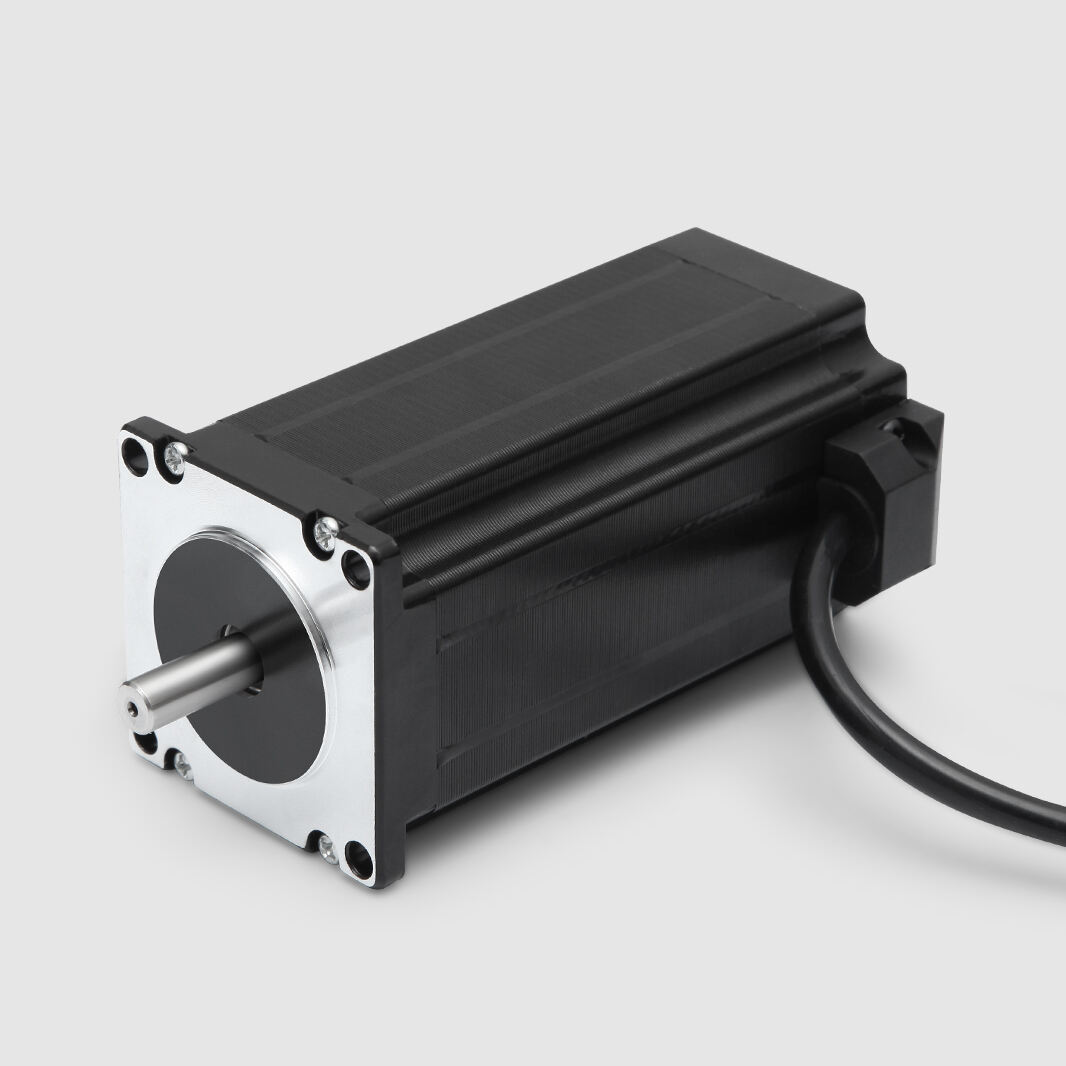

synchronous servo motor

The synchronous servo motor is a precision electrical device that combines the roles of a motor and a controller to deliver highly accurate and efficient motion control. Its main functions include converting electrical energy into mechanical energy with a high degree of precision and reliability. Technological features of the synchronous servo motor encompass a permanent magnet design, high-resolution feedback devices, and advanced control algorithms, which work in concert to ensure precise positioning, rapid response times, and consistent performance. These motors are utilized across a wide range of applications from industrial automation and robotics to precision machining and textile manufacturing, wherever fast, accurate, and repeatable movements are critical. With their robust design and ability to operate continuously without the risk of overheating, synchronous servo motors are an indispensable component in modern, high-performance machinery.