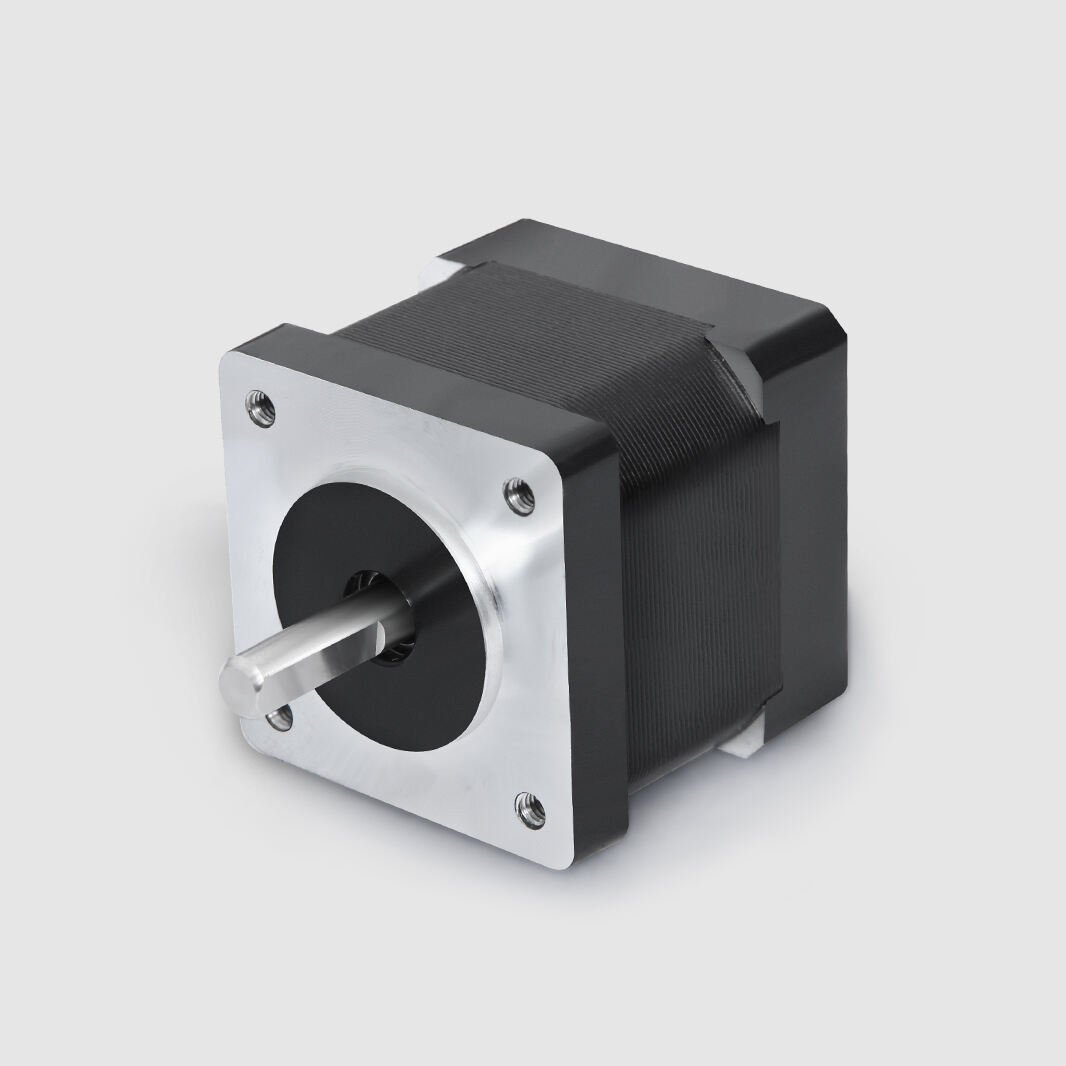

servo motor and controller

A servo motor and controller represent a sophisticated pairing of hardware that delivers precision control in a variety of mechanical applications. At the core of its functionality, the servo motor converts electrical signals into mechanical rotation, providing an exceptional level of accuracy and responsiveness. This is achieved through its main functions, which include receiving a control signal, comparing it to the motor's actual position, and making real-time adjustments to match the desired output. Technological features such as high-resolution encoders, robust gears, and advanced control algorithms allow for precise positioning, high torque, and excellent durability. These features make servo motors and controllers ideal for applications ranging from robotics and industrial automation to aerospace and medical devices, where precision and reliability are paramount.