servo linear motion

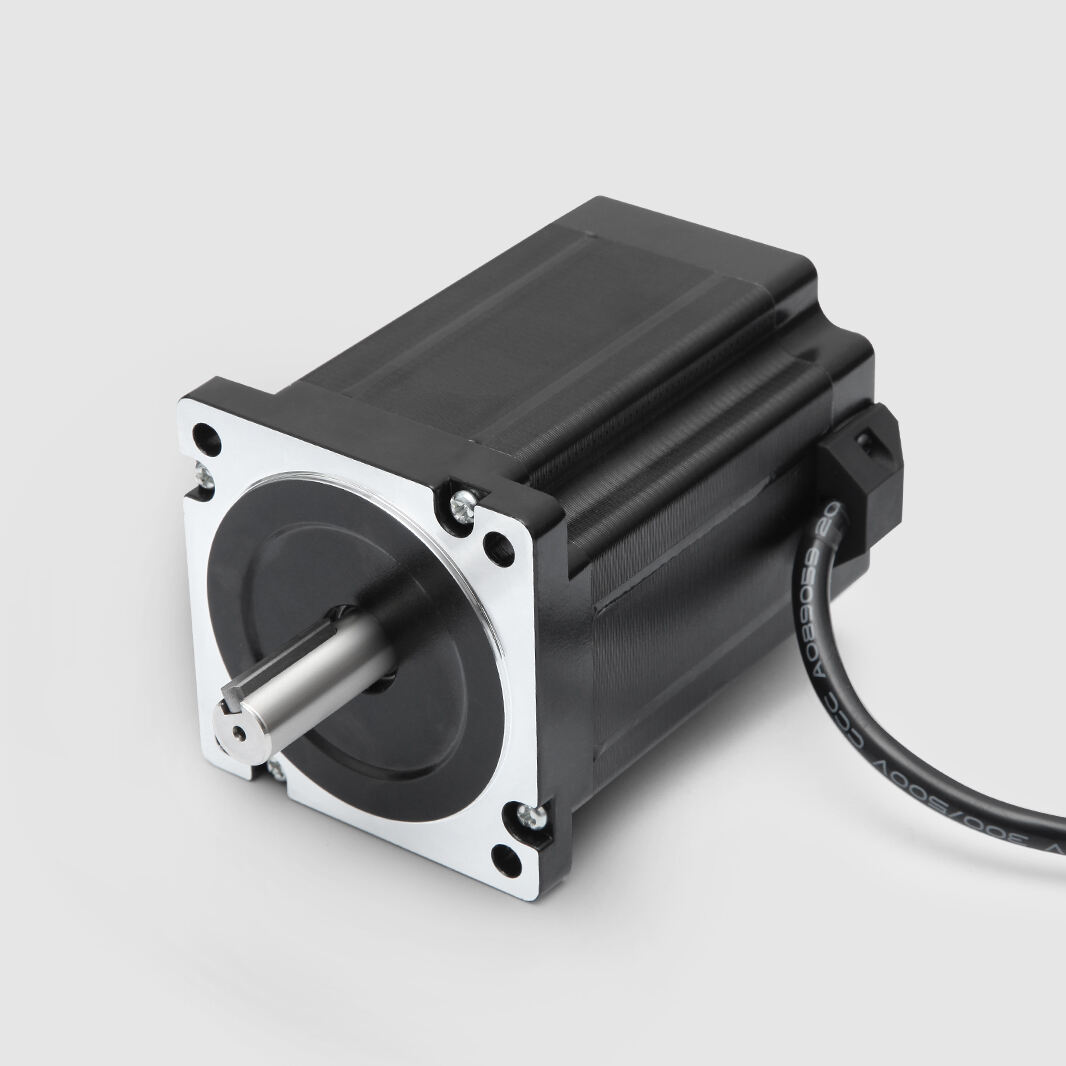

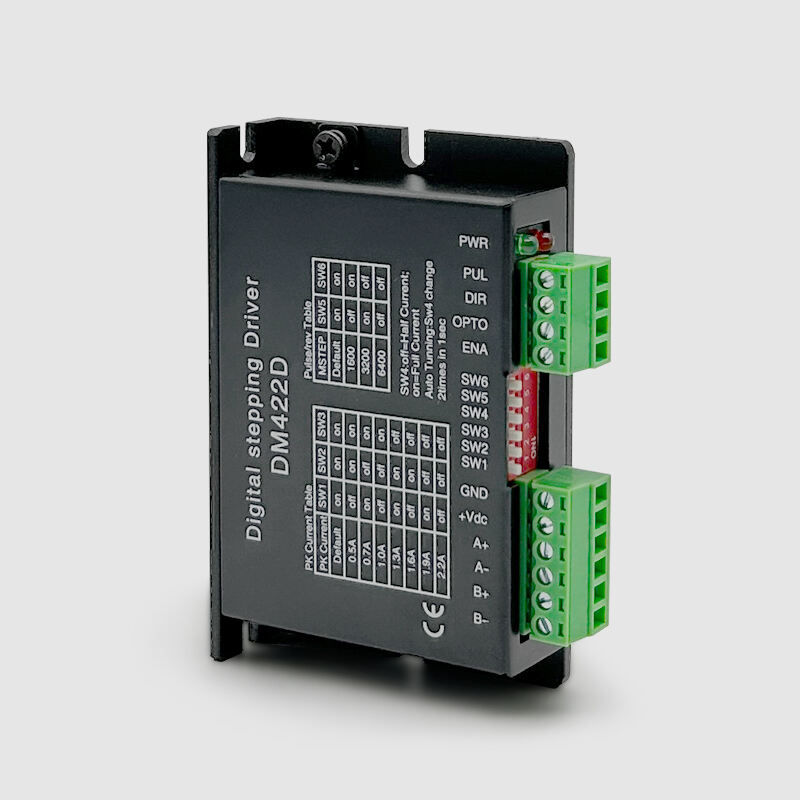

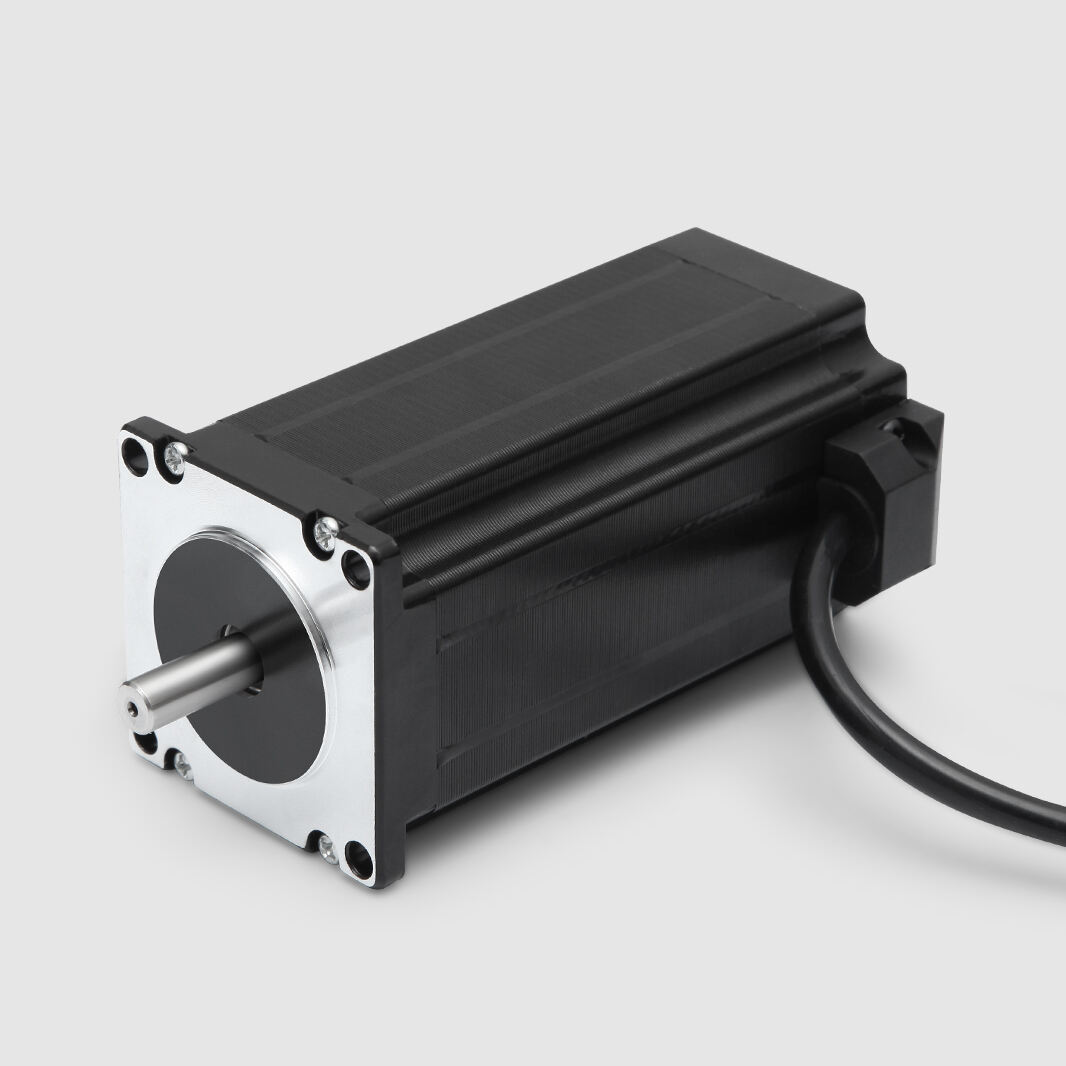

Servo linear motion is a precision engineering solution that involves the use of a servo motor combined with a linear guide to create controlled and accurate linear movement. The main functions of servo linear motion systems include positioning, transporting, and handling tasks with high precision and repeatability. Technological features such as closed-loop feedback mechanisms and advanced control algorithms enable these systems to maintain consistent performance even under varying loads and conditions. Common applications span across industries like manufacturing, robotics, and automation, where reliability and efficiency are paramount. The integration of a servo motor ensures that the system can be finely tuned to match the specific requirements of the application, resulting in improved productivity and reduced downtime.