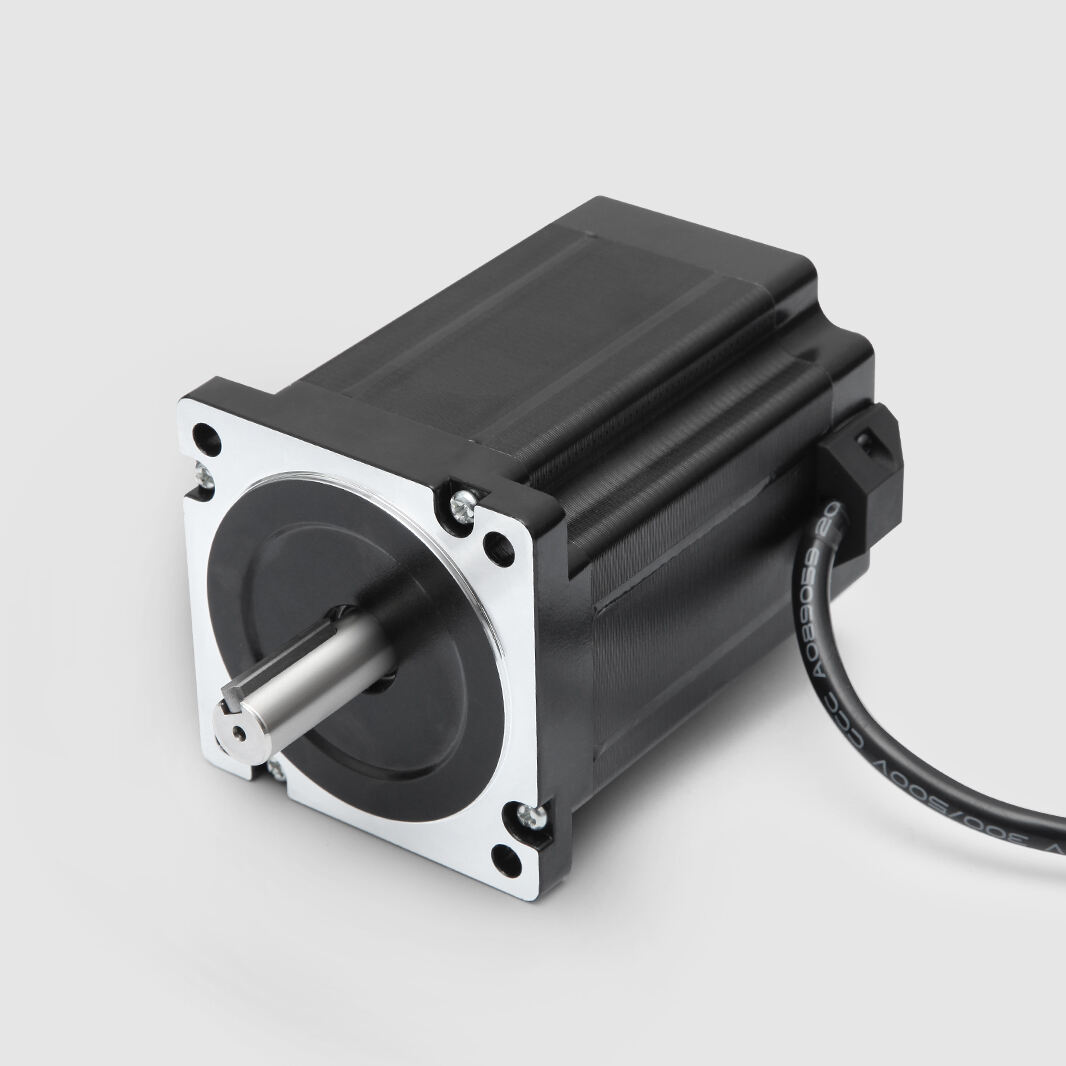

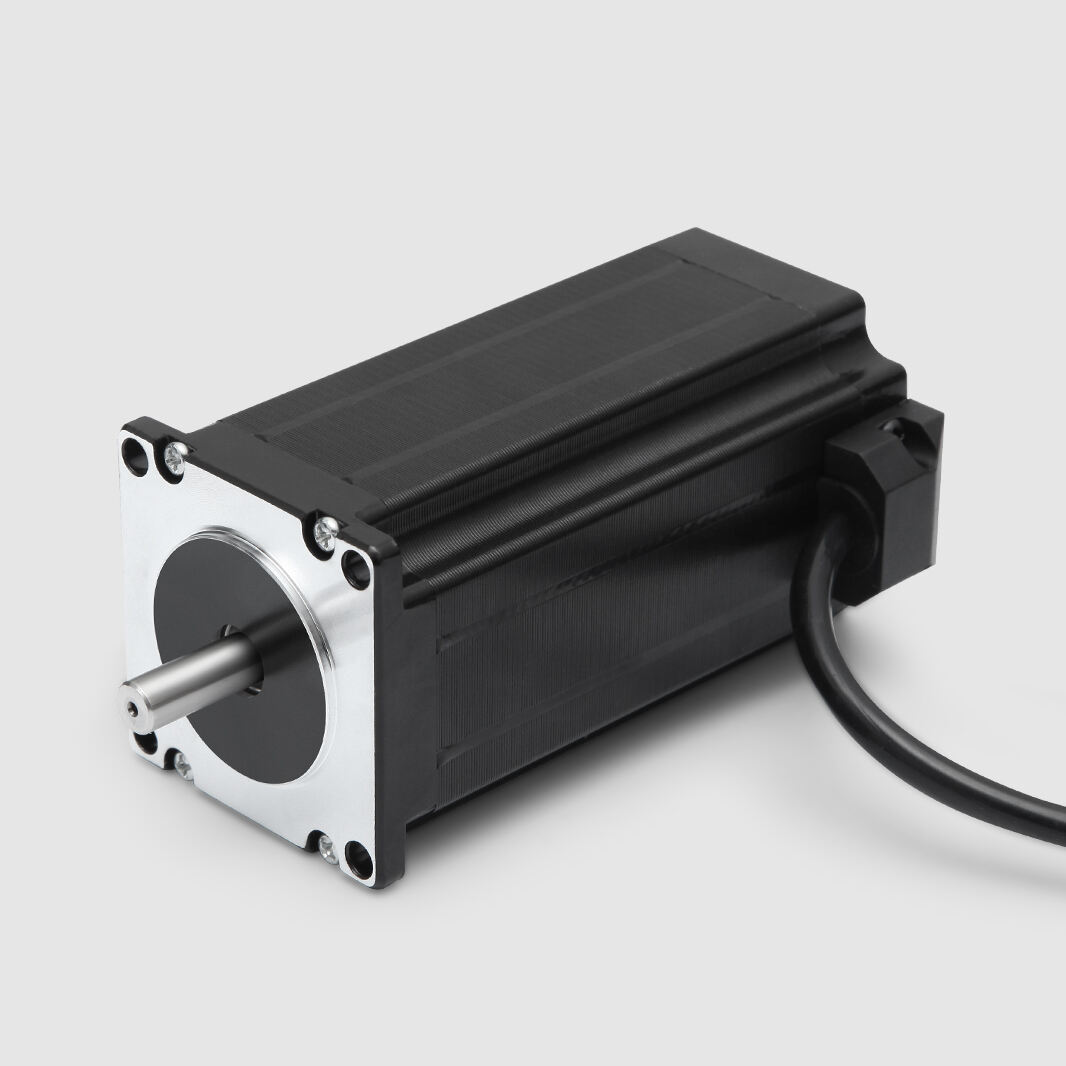

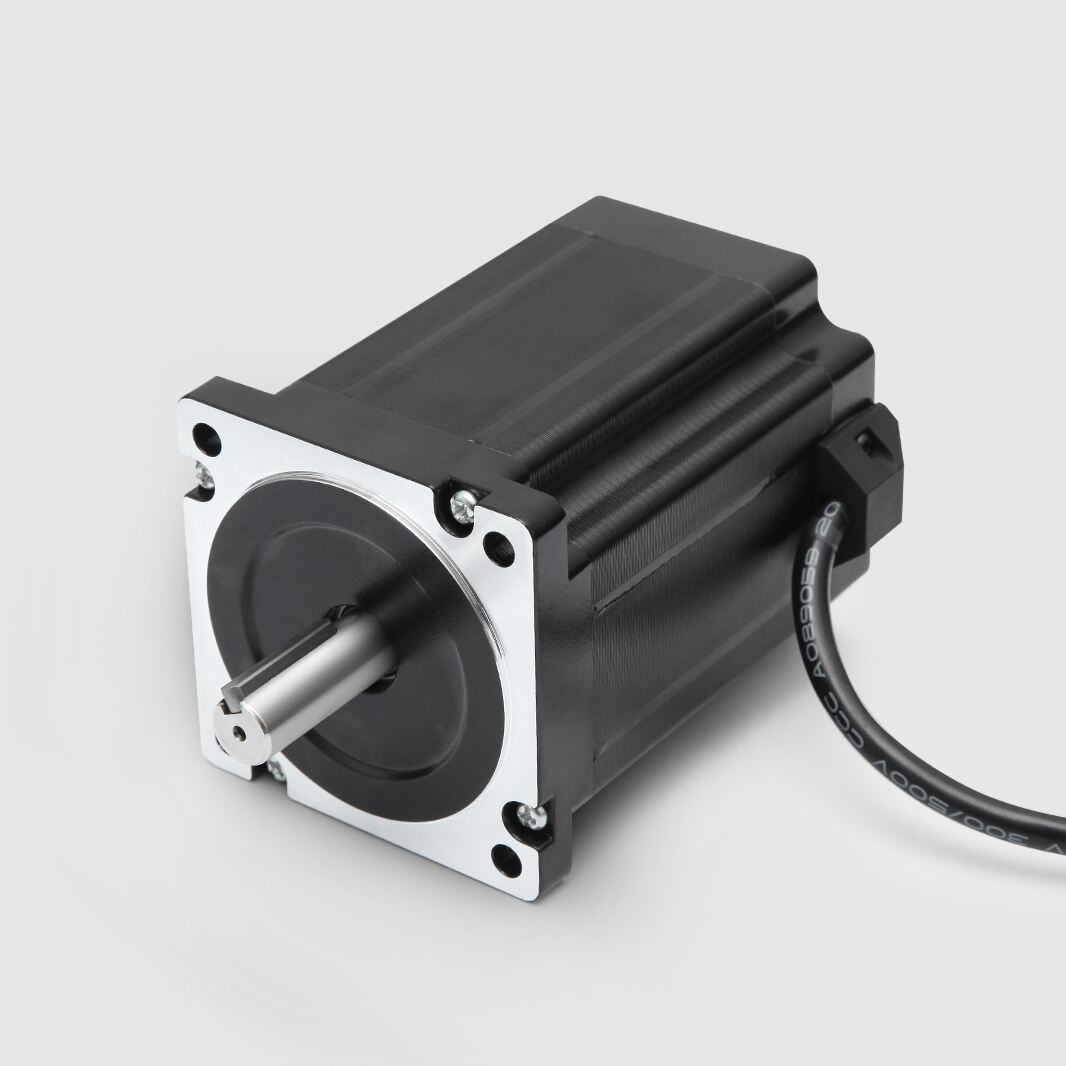

dc servo

The dc servo, short for direct current servo motor, is a type of electric motor that is widely used in applications requiring precise control of angular position, velocity, and torque. Its main functions include converting electrical energy into mechanical rotation and providing accurate motion control. Technological features of the dc servo motor encompass high responsiveness, low inertia, and a wide range of speed and torque capabilities. These features are enabled by its construction which typically includes a permanent magnet, an armature, and a feedback system consisting of a position sensor. This configuration ensures precise movement and positioning. DC servos find extensive use in robotics, industrial automation, aerospace, and consumer electronics, where the need for accuracy, reliability, and efficiency is paramount.