What Are the Common Issues With Stepper Motor Drivers and How Can They Be Resolved?

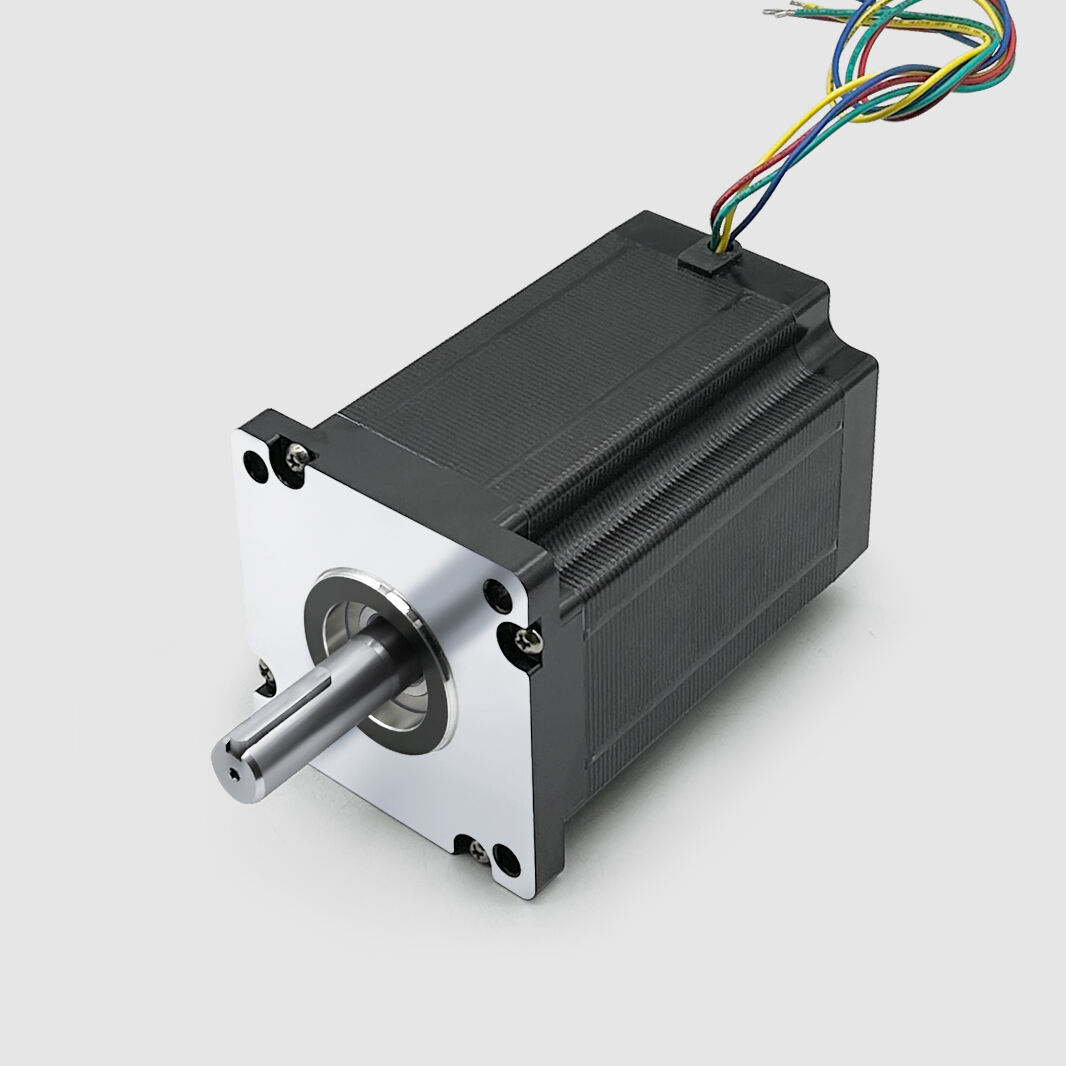

Common Issues With Stepper Motor Drivers and Their Causes Overheating and Excessive Noise Stepper motor drivers overheat through poor cooling – usually if it doesn’t have sufficient ventilation or any cooling recipients such as fan o...

View More