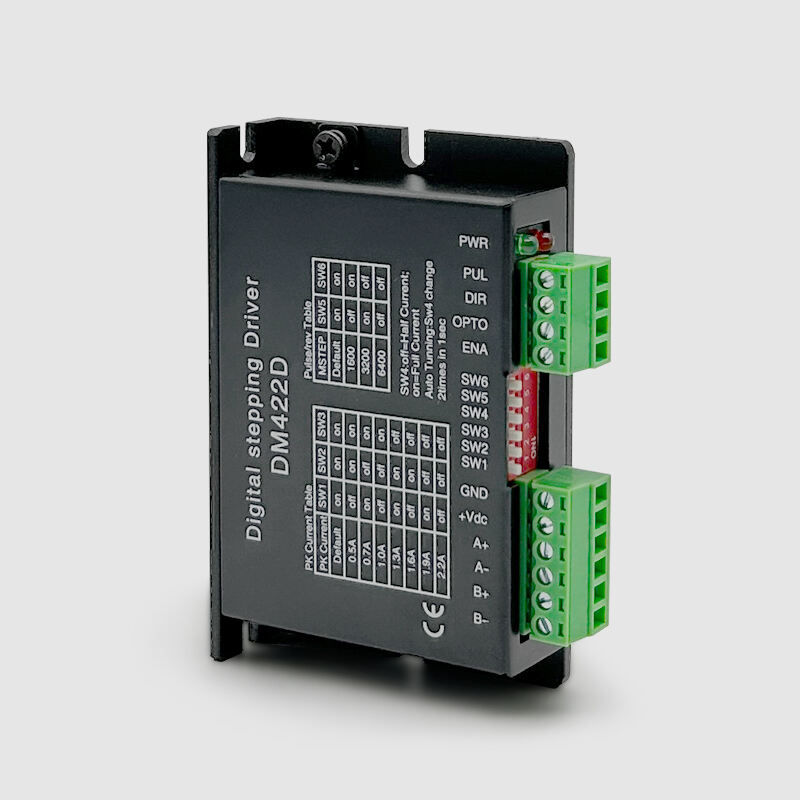

nema stepper driver

The NEMA stepper driver is a sophisticated piece of technology designed to control the motion of NEMA stepper motors with precision and efficiency. Main functions of this driver include converting digital signals into controlled mechanical movements, managing the motor's torque, speed, and position, and ensuring optimal performance through features like overcurrent and overvoltage protection. Technological features include compatibility with various motor sizes, a user-friendly interface, and advanced microstepping capabilities that enhance resolution and reduce vibrations. Common applications range from 3D printers and CNC machines to robotics and industrial automation systems, where precise movement and control are paramount.