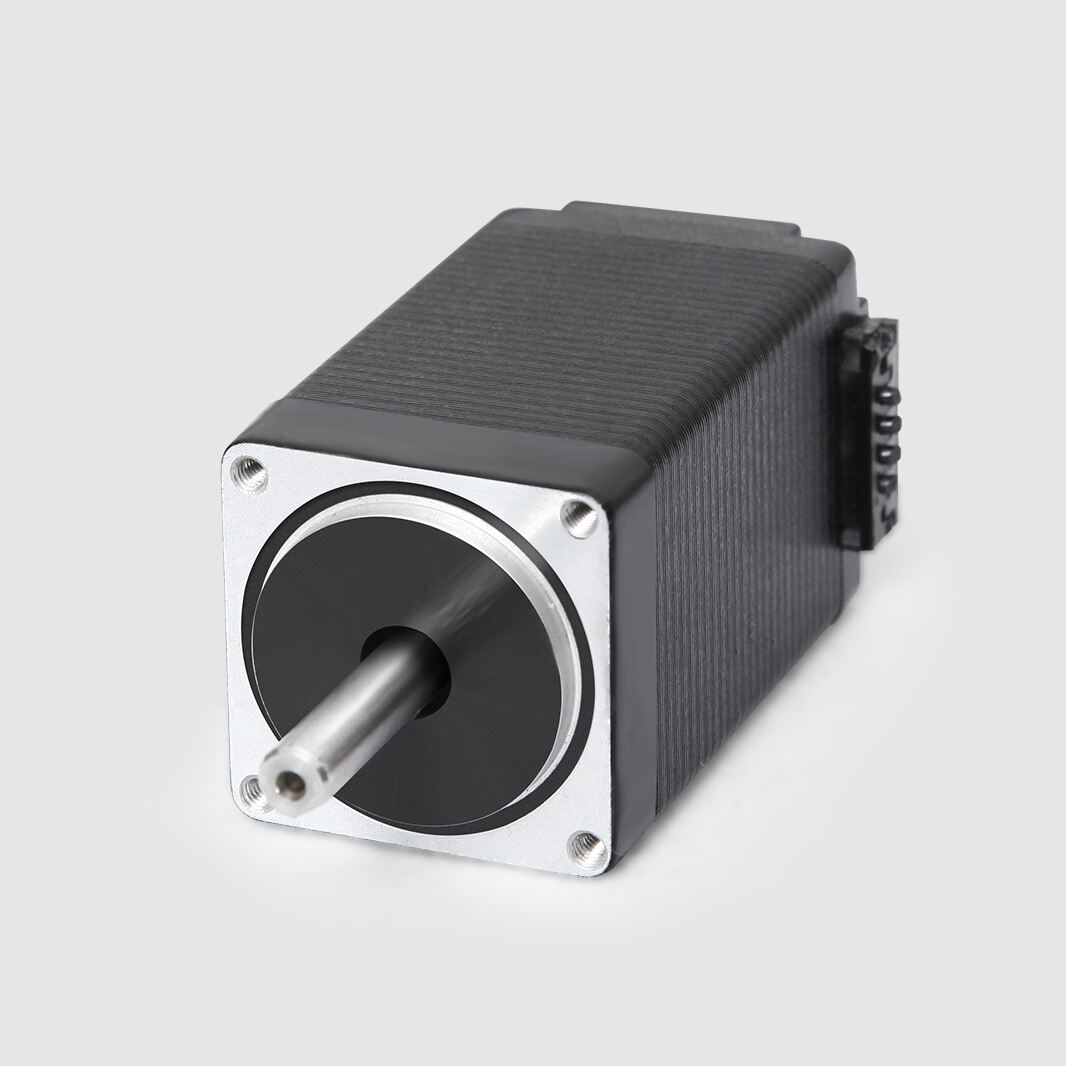

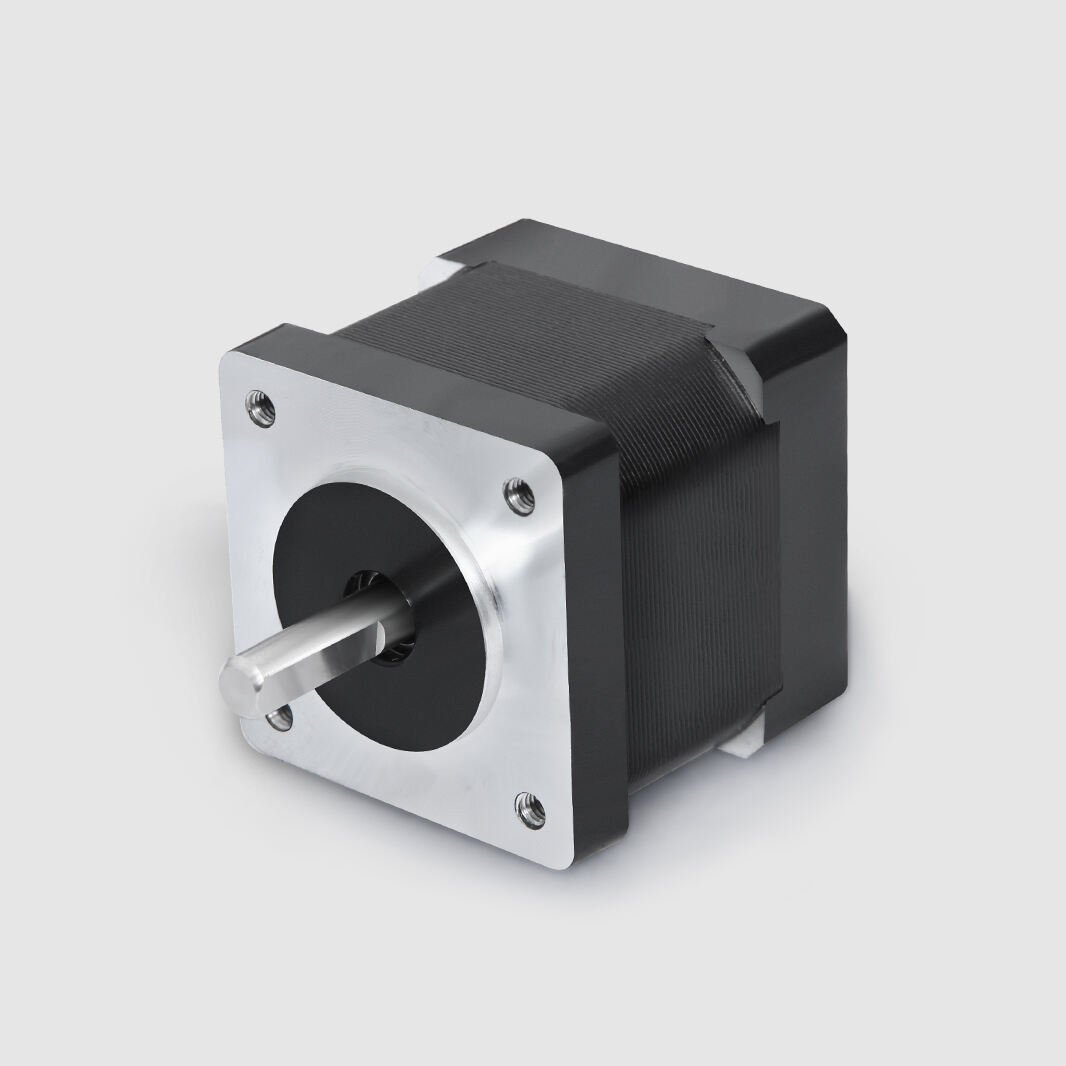

precise stepper motor

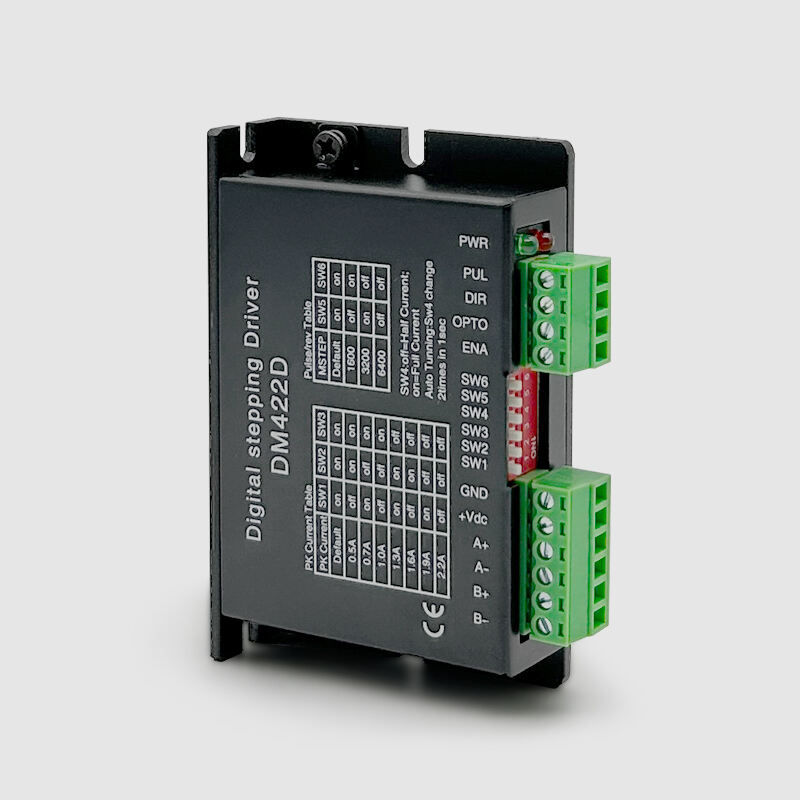

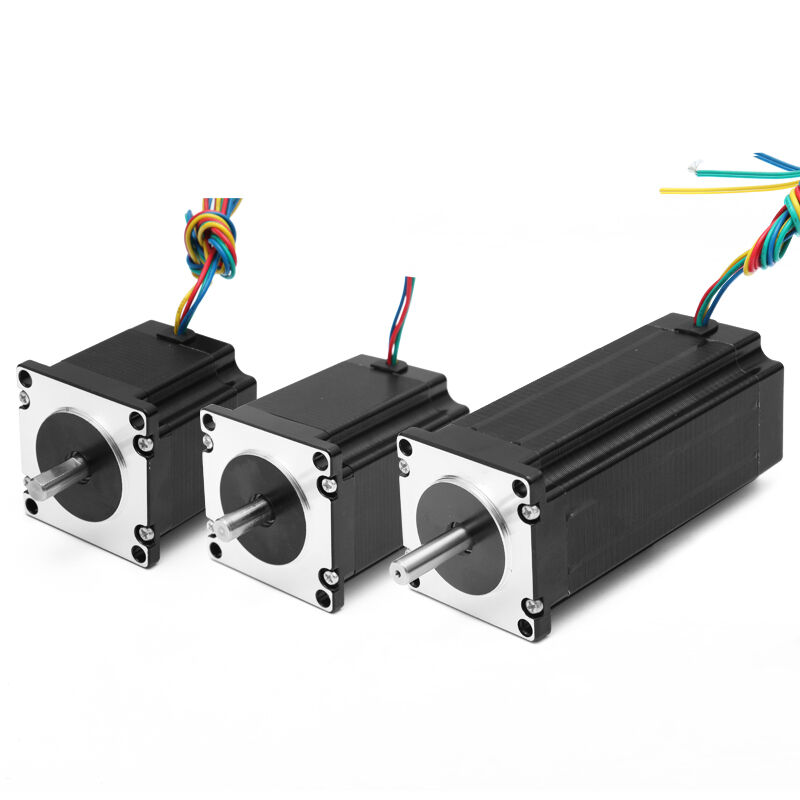

The precise stepper motor represents a revolutionary advancement in motion control technology, offering unparalleled accuracy and reliability for demanding industrial applications. This sophisticated electromechanical device converts digital pulses into precise mechanical rotation, making it an essential component in modern automation systems. Unlike traditional motors, the precise stepper motor operates without feedback sensors while maintaining exceptional positional accuracy, typically within 0.05 degrees per step. The motor's core functionality revolves around electromagnetic field manipulation, where carefully timed electrical pulses create rotating magnetic fields that drive the rotor in discrete, predictable increments. This digital control mechanism enables engineers to achieve exact positioning without complex feedback systems or encoders. The precise stepper motor incorporates advanced magnetic circuit designs, utilizing high-energy permanent magnets and optimized stator geometries to maximize torque density while minimizing power consumption. Modern variants feature microstepping capabilities, allowing subdivision of full steps into thousands of smaller increments, resulting in smoother operation and enhanced resolution. The motor's inherent ability to hold position without continuous power consumption makes it ideal for applications requiring static positioning accuracy. Key technological features include variable reluctance or hybrid construction, multi-phase winding configurations, and advanced driver electronics that enable sophisticated control algorithms. The precise stepper motor excels in applications demanding repeatable positioning, such as 3D printing, CNC machining, robotics, medical devices, and laboratory automation. Its open-loop control capability eliminates the need for expensive feedback devices while maintaining positional accuracy comparable to closed-loop servo systems. The motor's digital nature allows seamless integration with computer-controlled systems, enabling precise synchronization with other automated processes. Temperature stability, vibration resistance, and long operational life make the precise stepper motor suitable for harsh industrial environments where reliability is paramount.