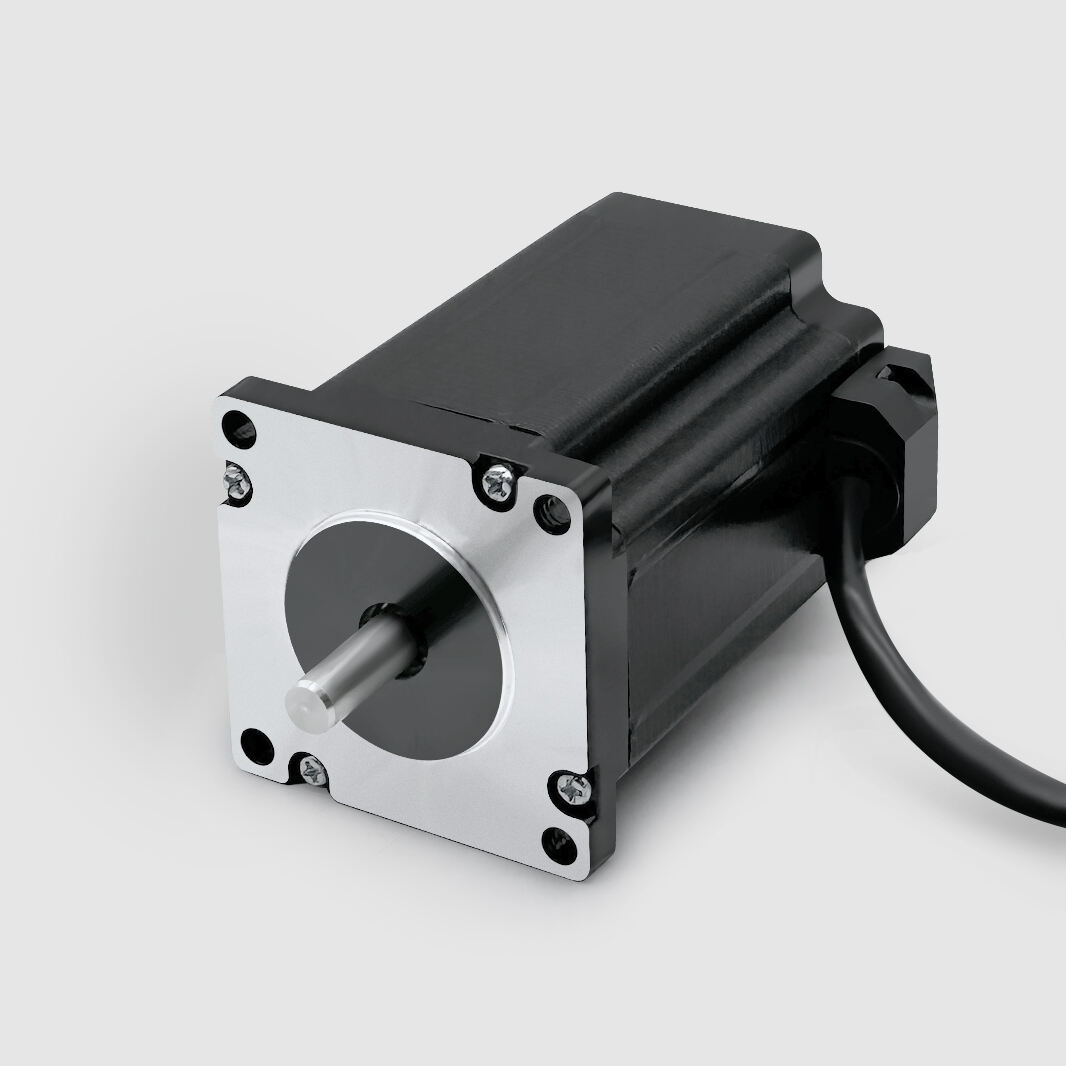

stepper motor for linear motion

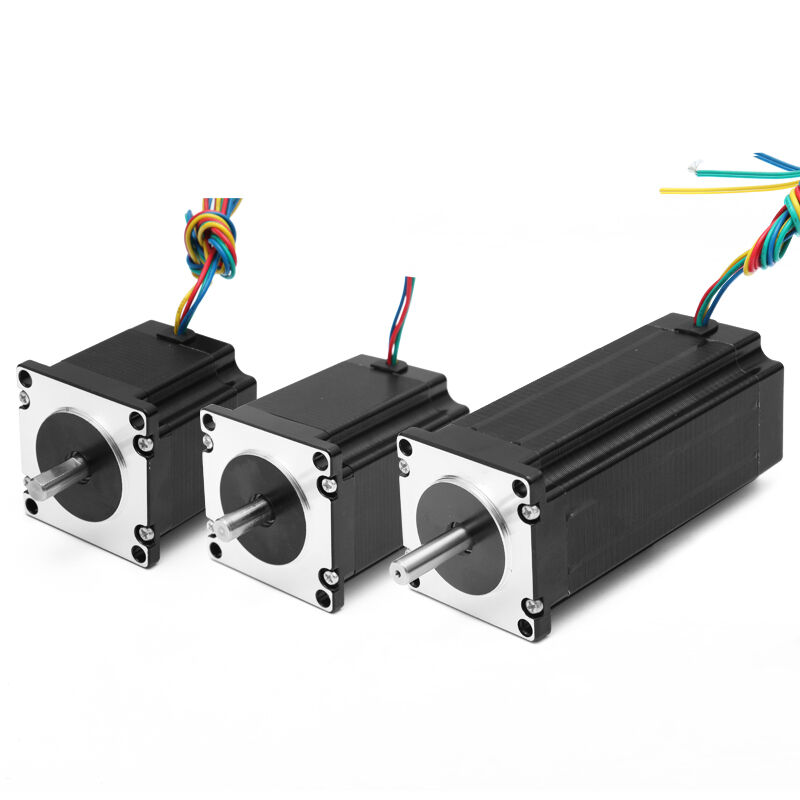

A stepper motor for linear motion represents an innovative solution that combines precise rotational control with direct linear displacement capabilities. This advanced electromechanical device transforms electrical pulses into exact linear movements without requiring complex mechanical conversion systems. The stepper motor for linear motion operates on electromagnetic principles, utilizing multiple coil windings that create controlled magnetic fields to drive a threaded shaft or lead screw mechanism. Each electrical pulse corresponds to a specific linear distance, typically measured in micrometers or millimeters, providing exceptional positioning accuracy. The primary function of a stepper motor for linear motion involves converting digital control signals into precise physical displacement along a straight path. This technology eliminates the need for traditional rotary-to-linear conversion mechanisms such as belt drives, rack and pinion systems, or complex gearing arrangements. The stepper motor for linear motion achieves this through integrated lead screws, ball screws, or specialized linear actuator designs that directly translate rotational motion into linear movement. Technologically, these motors feature multiple phases, commonly ranging from two to five phases, which enable smooth operation and enhanced torque characteristics. The stepper motor for linear motion incorporates advanced magnetic rotor designs with permanent magnets or variable reluctance configurations, ensuring consistent performance across varying load conditions. Modern versions include built-in encoders for position feedback, thermal protection circuits, and microprocessor-controlled drive electronics. Applications for stepper motor for linear motion span numerous industries including medical devices, laboratory automation, 3D printing, CNC machining, and precision manufacturing. In medical equipment, these motors provide accurate positioning for surgical instruments, imaging systems, and diagnostic tools. Manufacturing applications utilize stepper motor for linear motion technology in pick-and-place machines, assembly automation, and quality control systems. The aerospace industry employs these motors in satellite positioning systems, antenna alignment mechanisms, and flight control surfaces. Research laboratories depend on stepper motor for linear motion solutions for microscope positioning, sample handling, and analytical instrument automation.